Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TURUI

-

Voltage:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

3.6m*1.1m*2.1m

-

Weight:

-

1000

-

Machine:

-

Pvc Sheet Extruder Machine

-

Screw Diameter:

-

55/110

-

Material:

-

PVC Powder

-

Inverter:

-

DELTA AND ABB

-

Contactor:

-

France SCHNEIDER Contactors

-

Product:

-

PVC conduit trunking,PVC windows,PVC channels

-

Usage:

-

Plastic Forming Machine

-

Power:

-

22KW

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE ISO9001

Quick Details

-

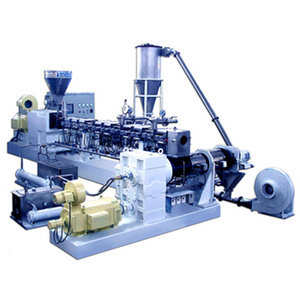

Screw Design:

-

Double-screw

-

Screw Speed (rpm):

-

1050 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

TURUI

-

Voltage:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

3.6m*1.1m*2.1m

-

Weight:

-

1000

-

Machine:

-

Pvc Sheet Extruder Machine

-

Screw Diameter:

-

55/110

-

Material:

-

PVC Powder

-

Inverter:

-

DELTA AND ABB

-

Contactor:

-

France SCHNEIDER Contactors

-

Product:

-

PVC conduit trunking,PVC windows,PVC channels

-

Usage:

-

Plastic Forming Machine

-

Power:

-

22KW

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE ISO9001

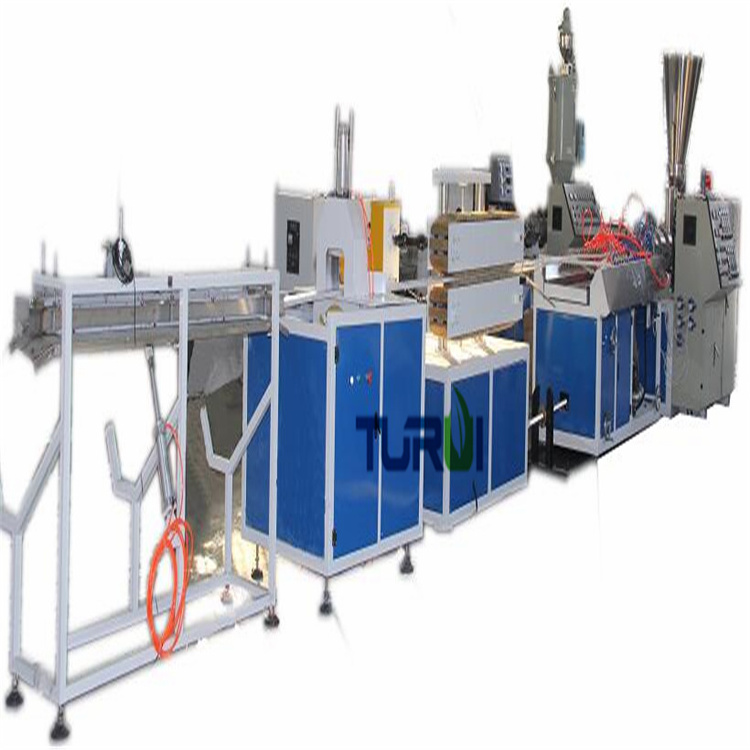

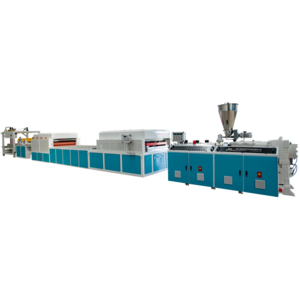

plastic pvc profiles production machine/extrusion line made in TURUI

Features for pvc wire conduit trunking extrusion machine:

* PLC control system is available

* All electrical components adopts famous brand : OMRON, ABB, SIEMENS etc

* Over current protective of motor

* With online protection film wrapping device

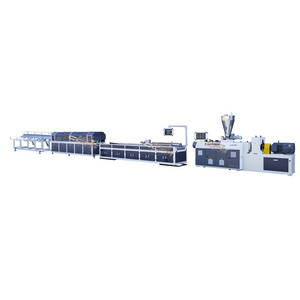

Process flow:

Raw material +wood power+ additive → mixing → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & pac

PART A:Conditions of production technology:

1, The application of supply voltage:380V/3 phase/50Hz

2, Raw materials:PVC power + auxiliary power(Like Calcium,CPE,ACR,PE wax,SA1801,Stabilizer)

3, Upon your request,we can offer you the formula,and guide price for additives in the market.

4, Maximum design output:80-150kg/h

(Note:Production may have a corresponding change in accordance with the processing of materials and different operating conditions)

5, Operation direction:Right To Left

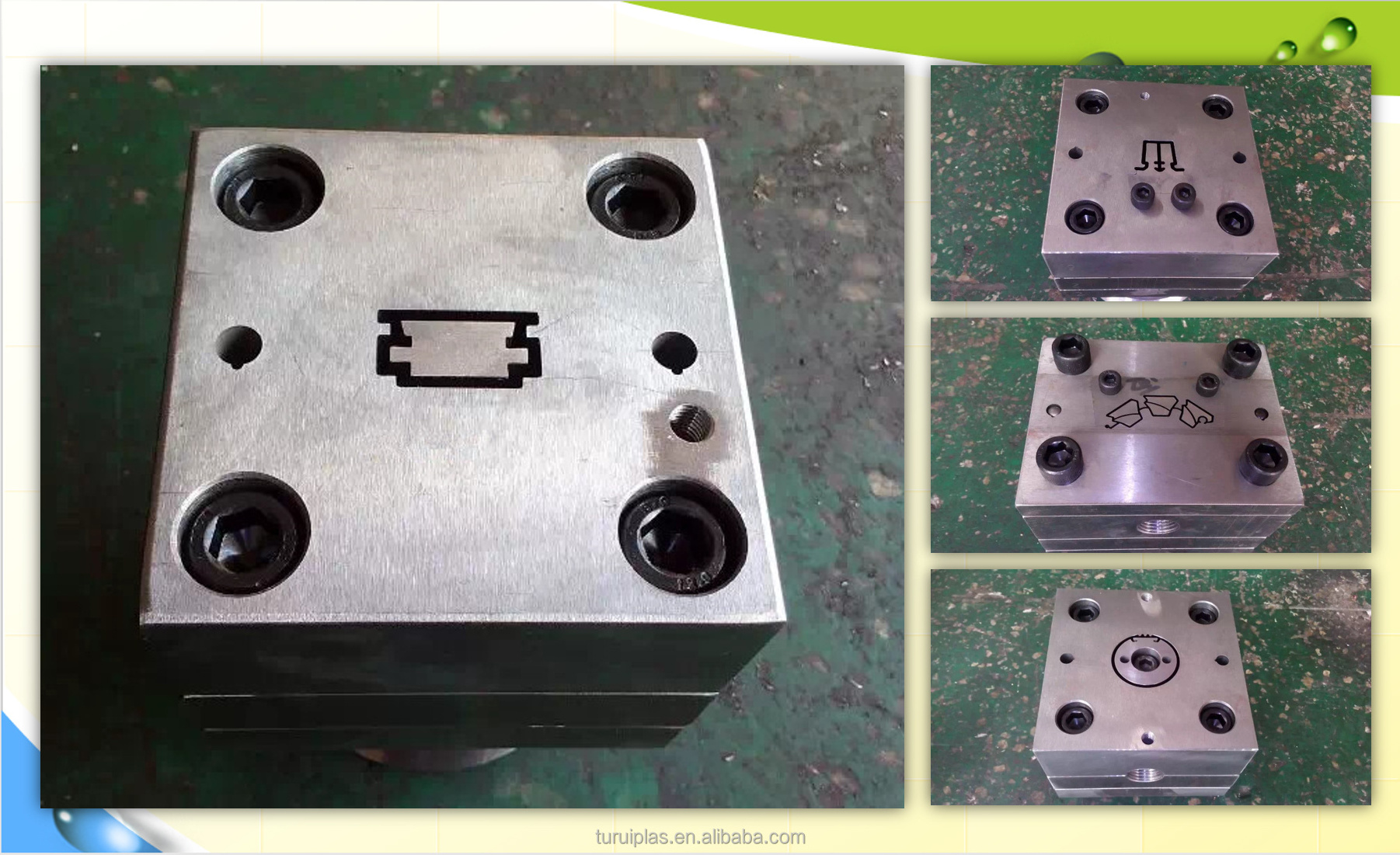

Die details

PVC profile

1.Any inquires will be replied in the first time.

2.High quality products, competitive price, fast lead time.

3.Our sales staff will be have a good communication with you ,let you fully understand the situation of our enterprises and products.

4.We will provide high quality overseas service ,our technical staff will be able to provide you with technical support ,for you personally to overseas assembly and test equipment.

5.Our customer service staff will put your feedback to the technical staff in the first time, timely solve your problem.

If you want any information about our production ,please contact with us!

melanie