- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Gap Filling

-

Material:

-

Polyuerthane

-

Shelf life:

-

12 Months

-

Packing:

-

12 Pcs/Carton

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

General Purpose One Component Polyurethane Foam

-

Color:

-

White

-

Application:

-

Gap Filling

-

Material:

-

Polyuerthane

-

Shelf life:

-

12 Months

-

Packing:

-

12 Pcs/Carton

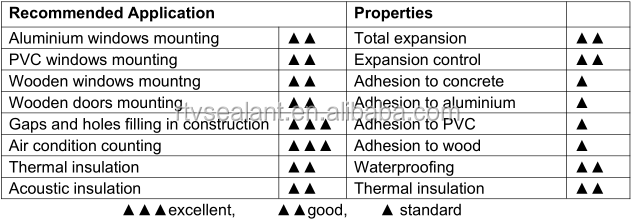

STC PU foam is one-component polyurethane foam which expands and cures through absorption of moisture from tha air. The product is recommended for mouncting windows and construction projects.The PU foam is available in gun/pipe applied version and with manual adaptor.

STC PU Foam is for all-season, all weather, multi-purpose use such as:

Mounting of window and door frames Sealing of all types of cracks and holes

Insulation of water-pipe network, central heating

Soundproofing of partition walls, car and boat cabins e tc.

PRODUCT FEATURES

Economically insulates, fills, seals and bonds Easy to use

Bonds to and seals most popular construction materials, wood, concrete, plaster, plumbing etc.

Excellent for interior and exterior applications

Durable airtight seal-stops air infiltration, drafts and energy loss

High insulating value-saves energy and money

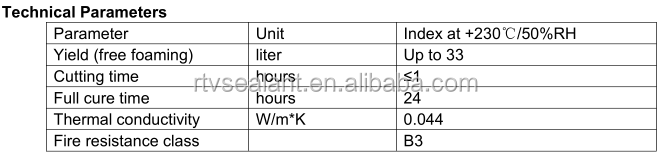

Technical Data:

|

Basic Component |

Polyurethane |

|

Type |

Gun type and straw type available |

|

Appearance |

Foam |

|

Color |

Light yellow |

|

Tack-Free Time ( min ) |

8 ~ 10 |

|

Cutting Time ( min ) |

30 ( +25 ℃ ) |

|

Density ( kg/m2) |

16 ~ 20 |

|

Yield ( L ) |

60 ~ 65 |

|

Thermal conductivity ( mW/ ( m·K )) |

< 34 |

|

Adhesive strength ( kPa ) |

> 80 |

|

Tensile strength(kPa) |

> 30 ( 10% ) |

|

Compressive strength(kPa) |

> 120 |

|

Close cells content% |

45 ~ 52 |

|

Water absorption(up to 24h) |

≤1.5% (no epidermis) |

|

Fire Class of the cured foam |

B3 |

|

Dimensional stability ( 23 ℃ ) |

0 ~ 1.0%(foaming direction) |

|

|

0 ~ 1.8%(flat direction) |

|

Environment |

Contains no CFC’s, no HCFC’s, Ozone friendly |

|

Toxicity of cured foam |

Non-toxicity |

|

Service temperature range of cured foam ℃ |

-40 to +100 |

|

Processing temperature range ℃ |

0 to +40 |

|

Shelf life(month) |

18 |

Surface preparation

Surface should be cleaned of dust and mortar colds

Surface should be sprayed with water using water sprayer

Protect window profiles from the foam's outgrow

HOW TO USE

1. Shake can well to make the foam ready for use

2. Clean the substrate and spray some water on it

3. Screw foam dispenser on tightly and turn can upside down

4. Vertical fills the gaps from the bottom upwards

5. Foam is tack-free (dry to the touch) in 7 to 15 minutes in temperatures between +18℃ and +25℃ (65℉ ~77℉). Higher temperatures will result in faster curing times

6. Remove fresh foam over spray with GORIVA Foam Cleaner or solvents such as acetone. Cured foam can only be removed mechanically.

PRODUCT STORAGE

Store in cool, dry area.

Do not expose to open flame.

Excessive heat can cause premature aging of components resulting in shorter shelf life.

PRODUCT