- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

2300x900x1800mm

-

Raw material:

-

Wood

-

Application:

-

Barbecue (BBQ)

-

Type:

-

Biomass Fule Briquetting Machine

-

Color:

-

Customers' Requirement

-

Keyword:

-

Sawdust Briquettes Charcoal Machine

-

Usage:

-

Make Coal Briquettes

-

Capacity:

-

300-600kg/h

-

Briquette Shape:

-

Square, Hexagon, Pillow, Pentagon, Hole, Columnar, Ball

-

Briquette size:

-

20-50mm

-

Certification:

-

CE

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

2300x900x1800mm

-

Raw material:

-

Wood

-

Application:

-

Barbecue (BBQ)

-

Type:

-

Biomass Fule Briquetting Machine

-

Color:

-

Customers' Requirement

-

Keyword:

-

Sawdust Briquettes Charcoal Machine

-

Usage:

-

Make Coal Briquettes

-

Capacity:

-

300-600kg/h

-

Briquette Shape:

-

Square, Hexagon, Pillow, Pentagon, Hole, Columnar, Ball

-

Briquette size:

-

20-50mm

-

Certification:

-

CE

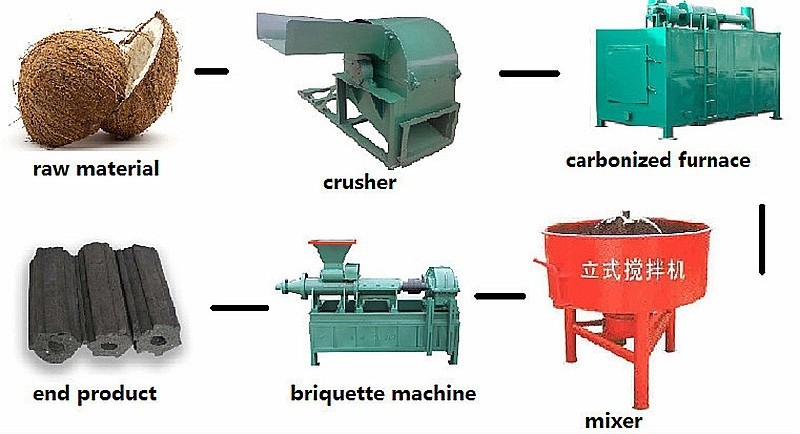

Product Application

Charcoal briquettes machine is known as biomass briquette machine, thanks to its raw materials come from all kinds of agro waste and forest residues. Therefore, starting a biomass charcoal briquette plant is very easy, if there are abundant biomass resource available, about built the charcoal biomass briquetting plant cost, our professional salesman very glad to give you suggestions to choose the most suitable type.

|

Specifications For Charcoal Briquettes Making Line

|

|

|

|

|

||||

|

Carbonization furnace

|

Model

|

YXC-1000

|

Cooling time

|

10-15hours

|

||||

|

|

Capacity

|

1000 kg/batch

|

Weight

|

4.5T

|

||||

|

|

Charring time

|

8-15hours

|

Machine size

|

5*1.6*2M

|

||||

|

Charcoal powder crusher

|

Model

|

YXC-500

|

Power

|

1.1KW

|

||||

|

|

Capacity

|

1000-2000 kg/h

|

Mesh

|

20-40

|

||||

|

Mixer

|

Capacity

|

500KG/H

|

Power

|

5.5KW

|

||||

|

Charcoal briquette press machine

|

Capacity

|

30000 pcs/h

|

Power

|

7.5KW

|

||||

|

|

Ф 30mm

|

12pcs/time

|

Diameter range

|

60mm - 1mm

|

||||

|

|

Ф 40mm

|

9pcs/time

|

Thickness range

|

16mm--0.5mm

|

||||

1. If your raw material is big block, you should choose a crusher.

2. If your raw material is with high moisture (higher than 12%), you should choose a dryer. If you prefer to use dry powder type briquette machine, the moisture should be less than 5%, also based on materials' performance.

3. Generally, it is better to add some binder/adhesive into the raw material. If you prefer to use dry powder type briquette machines, generally, no need binder.

4. About belt conveyor, you can buy from us, also can make by yourself. We would like to supply the detail drawing of conveyor for you.

5. The final briquettes can be dried under the sun or through mesh belt dryer and chain plate dryer.

What's your charcoal briquette look like?

The charcoal briquette mold and capacity can be customized for our client .