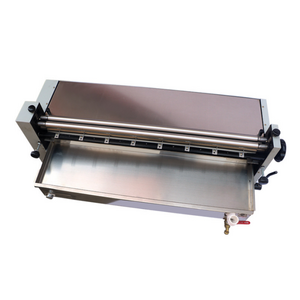

1. PUR hot-melt adhesive machine-adopts a gear motor controller and imported gear pump to precisely control the amount of glue.

2. Centralized control of PLC operation panel, easy to use and operate.

3. The cylinder and gear pump double work, and at the same time cooperate with the pressure regulating valve to make the glue

output pressure can be adjusted to maximize.

4. The tightness of the rubber cylinder is strong, avoiding the internal materials contacting the air during the working process

to cause deterioration.

5. It can be equipped with a single nozzle or flexible hot-melt hose, which can save costs by using one machine for multiple

purposes.

6. Pur hot melt adhesive machine has strong internal pressure-holding ability and constant temperature ability, which eliminates

and reduces gum carbonization and meets environmental protection and energy-saving requirements.

7. Forged high-pressure platen with imported technology, the melting speed is fast.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1070x500x1380mm

-

Weight:

-

100 KG, 100kg

-

Model Number:

-

PUR-050C

-

Inner diameter of barrel:

-

280/286mm

-

Maximum operating temperature:

-

180℃

-

Output line:

-

1-2

-

Useage:

-

Woodworking,printing, packaging, clothing, shoes, , furniture, etc

-

MOQ:

-

1set

-

Warranty Service:

-

Online support

-

warranty period:

-

1year

-

Maximum viscosity:

-

50000Cps

Quick Details

-

Voltage:

-

AC380V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KEQIRUI

-

Dimension(L*W*H):

-

1070x500x1380mm

-

Weight:

-

100 KG, 100kg

-

Model Number:

-

PUR-050C

-

Inner diameter of barrel:

-

280/286mm

-

Maximum operating temperature:

-

180℃

-

Output line:

-

1-2

-

Useage:

-

Woodworking,printing, packaging, clothing, shoes, , furniture, etc

-

MOQ:

-

1set

-

Warranty Service:

-

Online support

-

warranty period:

-

1year

-

Maximum viscosity:

-

50000Cps

Product Overview

PUR-050C

Advantage:

Equipment features:

1. The design of the whole machine is composed of two parts: mechanical and electrical control system, which has reasonable

structure, convenient operation and maintenance, and increased internal space, so that there is enough space for heat dissipation

in the electronic control box, greatly reducing the damage of electronic components and power loss.

2. The connection mode of the gear pump and the motor is connected by a universal joint. Its function is to make the angle between

the two ends of the transmission shaft equal, to ensure that the instantaneous angular speed of the output shaft and the shaft

input shaft is always equal, and to ensure the stability of the melter in high-speed operation. , Evenly.

3. The pressure plate is made of aluminum alloy precision casting and processed by precision processing technology. The surface

layer is formed by DuPont Teflon deep penetration sintering treatment surface. It has the advantages of high coating strength and

is not easy to fall off, reducing the phenomenon of hot melt adhesive carbonization. .

4. The main machine adopts high-precision return valve (return valve sensitivity ± 1bar). It is equipped with a locking function

to avoid damage to equipment or personnel due to operational errors. The filter design of the whole machine adopts heavy

multi-layer filtration to prevent PUR When the glue expires, it is suspected that it causes blockage, and the inside of the

pressure plate is protected by overpressure of pur glue to ensure the stable and reliable operation of the system.

structure, convenient operation and maintenance, and increased internal space, so that there is enough space for heat dissipation

in the electronic control box, greatly reducing the damage of electronic components and power loss.

2. The connection mode of the gear pump and the motor is connected by a universal joint. Its function is to make the angle between

the two ends of the transmission shaft equal, to ensure that the instantaneous angular speed of the output shaft and the shaft

input shaft is always equal, and to ensure the stability of the melter in high-speed operation. , Evenly.

3. The pressure plate is made of aluminum alloy precision casting and processed by precision processing technology. The surface

layer is formed by DuPont Teflon deep penetration sintering treatment surface. It has the advantages of high coating strength and

is not easy to fall off, reducing the phenomenon of hot melt adhesive carbonization. .

4. The main machine adopts high-precision return valve (return valve sensitivity ± 1bar). It is equipped with a locking function

to avoid damage to equipment or personnel due to operational errors. The filter design of the whole machine adopts heavy

multi-layer filtration to prevent PUR When the glue expires, it is suspected that it causes blockage, and the inside of the

pressure plate is protected by overpressure of pur glue to ensure the stable and reliable operation of the system.

High-performance customized cylinder

Teflon® Coated Platen

Programmable controller and servo

Workshop

Specification

|

Product name

|

PUR Hot melt adhesive machine

|

|

Inner diameter of barrel

|

5 Gallons

|

|

Model / System

|

PUR-050c

|

|

Maximum working temperature

|

180°C

|

|

Maximum viscosity(Cps)

|

50000

|

|

Number of rubber output

|

1-2

|

|

Temperature control mode

|

touch screen

|

|

power

|

9kw

|

|

Dimensions

|

1070*500*1380mm

|

|

Circuit requirements

|

AC 380V/50HZ

|

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

Manual glue gun or automatic glue gun can be chose;

Glue output way, bead spraying, strip spraying, spiral spraying, scrape spraying, Fiberized spraying.Accept the customized nozzle

service.

Glue output way, bead spraying, strip spraying, spiral spraying, scrape spraying, Fiberized spraying.Accept the customized nozzle

service.

Successful project

project1

project2

project3

Similar products

Contact US

For more info.

lf you want to know more information please feel free to contact me.

Thank you!

Guangzhou KEQIRUI Machinery Equipment Co., Ltd

Shiloh

Sales Manager

E-mail: keqiruisales@163.com

Mob/Wechat/WhatsApp/facebook:

+86 13352802879

www.keqirui.com

Thank you!

Guangzhou KEQIRUI Machinery Equipment Co., Ltd

Shiloh

Sales Manager

E-mail: keqiruisales@163.com

Mob/Wechat/WhatsApp/facebook:

+86 13352802879

www.keqirui.com

FAQ

Q: Are you the factory or trading company?

A: We are professional manufacturer for Hot Melt Glue Machine/ dispenser since 2012;

Q: What is your Minimum Order Quantity of your Product?

A: Normally the MOQ is 1 set;

Q: What's your after-sales service?

A: Free online technology services 24h hours;

Q: Where is the factory location?

A: The Guangzhou Keqirui Machinery Equipment Co., Ltd. is located in Huadu District, Guangzhou City,Guangdong Province, China;

Q:Whether the products can be made of different standard?

A: Of course yes. We could produce product according to custom need.

Q: Do you provide samples?

A: Yes, i set ample order is acceptable.

Q: How about the warranty?

A: 1 year.

Q; What about package?

A: Cartons with foam inside & wooden case.

A: We are professional manufacturer for Hot Melt Glue Machine/ dispenser since 2012;

Q: What is your Minimum Order Quantity of your Product?

A: Normally the MOQ is 1 set;

Q: What's your after-sales service?

A: Free online technology services 24h hours;

Q: Where is the factory location?

A: The Guangzhou Keqirui Machinery Equipment Co., Ltd. is located in Huadu District, Guangzhou City,Guangdong Province, China;

Q:Whether the products can be made of different standard?

A: Of course yes. We could produce product according to custom need.

Q: Do you provide samples?

A: Yes, i set ample order is acceptable.

Q: How about the warranty?

A: 1 year.

Q; What about package?

A: Cartons with foam inside & wooden case.

Hot Searches