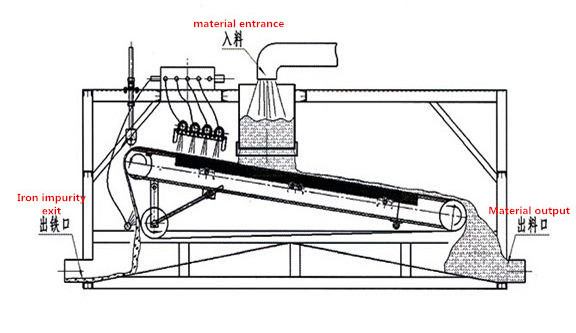

Under the action of gravity, the slurry flows downward along the inclined direction of the magnetic plate.

The ferromagnetic material contained in the slurry is firmly adsorbed on the iron-removing belt under the strong magnetic field provided by the magnetic plate,

the motor drive the