- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer Local Standard

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

10000 KG

-

Core Components:

-

Coil

-

Application:

-

Beneficiation of weakly magnetic minerals

-

Induced field intensity:

-

up to 24000 Gauss

-

Feeding size:

-

-1 mm

Quick Details

-

Production Capacity:

-

Varies

-

Place of Origin:

-

Shandong, China

-

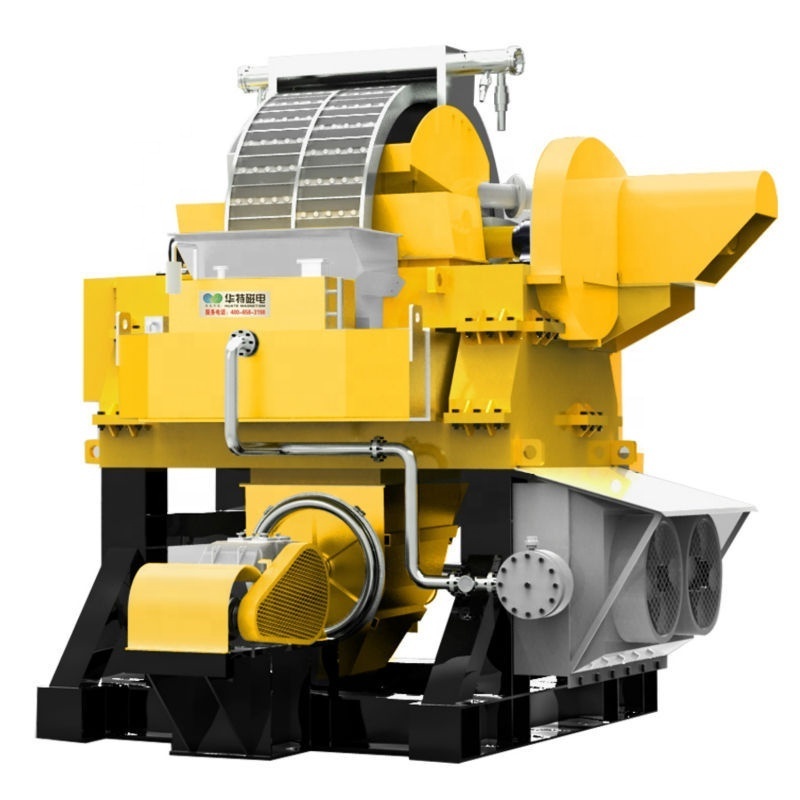

Brand Name:

-

Huate

-

Voltage:

-

Customer Local Standard

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

10000 KG

-

Core Components:

-

Coil

-

Application:

-

Beneficiation of weakly magnetic minerals

-

Induced field intensity:

-

up to 24000 Gauss

-

Feeding size:

-

-1 mm

Product Description

Application:

Vertical ring w

et high gradient magnetic separator is used for wet beneficiation of particles below 1.2 mm (30~100% passing 200 mesh) of fine-grained liberated red ore (hematite), limonite, manganese ore, ilmenite and other kinds of weakly magnetic minerals, and can also be used for removing of iron impurity and purification of non-metallic minerals, such as silica sand, feldspar, nepheline, kaolin.

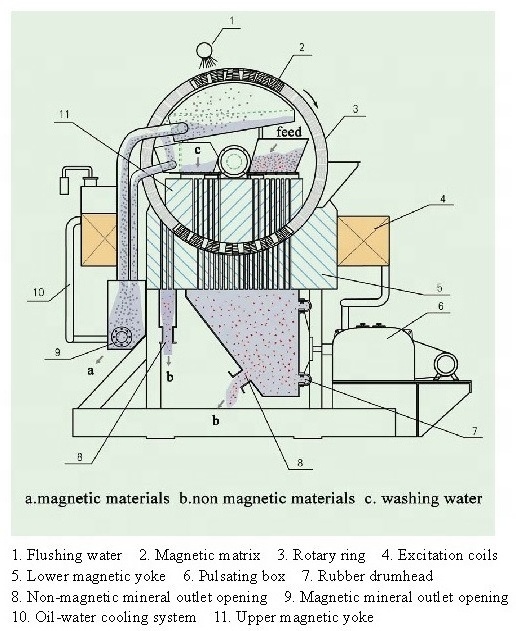

Working Principle:

Slurry is introduced to the matrix - housed inside the vertical separating ring - through slots in the upper yoke. The magnetic particles are attracted to the matrix and are then carried outside the magnetic field where they are subsequently flushed to the magnetic concentrate trough. The non-magnetic, or less magnetic, particles pass through the matrix through slots in the lower yoke to the non-magnetic collection hoppers.

Technical Features

1. The oil-water cooling vertical ring high gradient magnetic separator has an advanced cooling system. The coil is fully sealed and with forced oil-cooling external circulation. The principle of oil-water heat exchange is adopted, and the heat generated by the coil is quickly taken away by the flush water, so that the coil temperature rise is less than 25 °C, and the magnetic field thermal decay is minimal.

2. Both ends of the coil are wrapped with iron shields, which improves the magnetic energy utilization rate, and increases the magnetic field strength in the separation area by more than 8%, and the background magnetic field is above 1.4 T.

3. The coil housing is fully sealed, rainproof, dustproof and corrosion resistant, ensuring that the equipment can work in a variety of harsh environments.

4. Using the flushing water to cool the transformer oil, which eliminates the need for additional cooling water, saves the energy, protects the environment and saves water resources.

5. The magnetic medium is a rod medium structure with different cross-sections, adopting a four-point restraint mechanism, having large magnetic field gradient, high field strength and long service life.

6. With advanced fault diagnosis system and remote control system, realizing intelligent operation control of equipment.

7. Optional pneumatic-water flushing and pulsation device can be equipped according to the characteristics of different materials, featuring high flushing efficiency, good separation effect and low water consumption.

2. Both ends of the coil are wrapped with iron shields, which improves the magnetic energy utilization rate, and increases the magnetic field strength in the separation area by more than 8%, and the background magnetic field is above 1.4 T.

3. The coil housing is fully sealed, rainproof, dustproof and corrosion resistant, ensuring that the equipment can work in a variety of harsh environments.

4. Using the flushing water to cool the transformer oil, which eliminates the need for additional cooling water, saves the energy, protects the environment and saves water resources.

5. The magnetic medium is a rod medium structure with different cross-sections, adopting a four-point restraint mechanism, having large magnetic field gradient, high field strength and long service life.

6. With advanced fault diagnosis system and remote control system, realizing intelligent operation control of equipment.

7. Optional pneumatic-water flushing and pulsation device can be equipped according to the characteristics of different materials, featuring high flushing efficiency, good separation effect and low water consumption.

Technical Specifications

|

Model No.

|

LHGC- 1000F

|

LHGC- 1500F

|

LHGC- 1750F

|

LHGC- 2000F

|

LHGC- 2250F

|

LHGC- 2500F

|

LHGC- 3000F

|

LHGC- 3600F

|

||||||||

|

Background magnetic field (T)

|

1.0/

1.4

continuously adjustable

|

|

|

|

|

|

|

|

||||||||

|

Rated excitation power (kW)

|

17/

28

|

27/

48

|

37/

58

|

42/

70

|

51/

73

|

57/

76

|

74/

108

|

90/

115

|

||||||||

|

Solids capacity (t/h)

|

2 ~3.5

|

10 ~15

|

15 ~25

|

25 ~40

|

40 ~60

|

50 ~75

|

75 ~125

|

125~200

|

||||||||

|

Pulp capacity (m3/h)

|

12.5~20

|

50 ~100

|

75 ~150

|

100~200

|

160~300

|

200~400

|

350~650

|

550~950

|

||||||||

|

Feed concentration (%)

|

10~35

|

|

|

|

|

|

|

|

||||||||

|

Feed size(mm)

|

-1.2

|

|

|

|

|

|

|

|

||||||||

|

Ring rotation speed (r/min)

|

2~3

|

|

|

|

|

|

|

|

||||||||

|

Ring outer diameter (mm)

|

1000

|

1500

|

1750

|

2000

|

2250

|

2500

|

3000

|

3600

|

||||||||

|

Motor power for ring rotation (kW)

|

1.1

|

3

|

4

|

5.5

|

7.5

|

11

|

18.5

|

30

|

||||||||

|

Motor power for pulsation (kW)

|

2.2

|

4

|

4

|

7.5

|

7.5

|

11

|

18.5

|

30

|

||||||||

|

Flushing water pressure (MPa)

|

0.2~0.4

|

|

|

|

|

|

|

|

||||||||

|

Flushing water consumption (m3/h)

|

8 ~12

|

20 ~30

|

30 ~50

|

40 ~80

|

60 ~100

|

80 ~120

|

120~220

|

150~250

|

||||||||

|

Machine weight (t)

|

9.5/

13

|

24/

27

|

35/

48

|

48/

60

|

75/

85

|

105/

120

|

165/

185

|

275/

310

|

||||||||

|

Weight of the heaviest part (t)

|

2.3/

3.3

|

8/

10

|

13/

18

|

16/

22

|

25/

28

|

23/

32

|

24/

35

|

32/

36

|

||||||||

|

Note: The data in blue is for 1.4 T background magnetic field.

|

|

|

|

|

|

|

|

|

||||||||

Related Products

Production Flow

Hot Searches