- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw-18kw

-

Weight:

-

200KG-2000KG

-

Dimension(L*W*H):

-

800*800*1200MM

-

Processing Types:

-

bottle

-

Certification:

-

CE ISO SGS

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

King Machine

-

Voltage:

-

220V/380V

-

Power:

-

2.2kw-18kw

-

Weight:

-

200KG-2000KG

-

Dimension(L*W*H):

-

800*800*1200MM

-

Processing Types:

-

bottle

-

Certification:

-

CE ISO SGS

|

Containers and specifications

|

|

|

|

|

||||

|

Project Name:

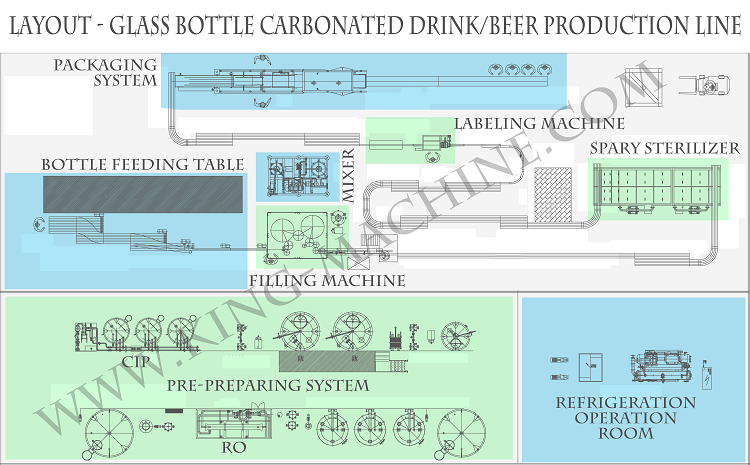

Complete full automatic 3-in-1 glass bottle beer filling machine 400-25000BPH |

|

|

|

Carbonated water

/ Soft Drink / Beer |

||||

|

Material

|

Shape

|

Filling volume

|

Filling level(mm)

|

Cap type

|

||||

|

Glass Bottle

|

Round Bottle

|

200-2000ml

|

Distance from bottle neck

According request

|

Screw cap

Crown cap |

||||

|

Adjustable specifications of the bottle type

|

【Middle Mould Base】Bottle diameter Φ50~Φ85mm Bottle Height 105~300mm

|

|

|

|

||||

|

|

Customers need to buy additional change-over parts for the different bottles.

If using square bottles, then bottle separating system will be added. |

|

|

|

||||

|

Carbonated Drink

Preparation |

Syrup melter/ Mixing machine/Filter/Co2 Filter/CO2 Mixer .....

|

|

|

|

||||

|

Machine Filling

Processing |

Washing bottle --- CO

2

into bottle --- Vacuum --- CO

2

--- Vacuum --- Filling Beer --- Capping

|

|

|

|

||||

|

Container Label & Control Mode

|

|

Packaging system

|

|

Palletizing system

|

||||

|

Hot Melt Roll-Fed

PVC Shrink Label

Full Label/ Half Label

Manual / Automatic

|

|

Packing system

|

Min, Spec.

|

Manual

Low position gantry palletizer

Robot Palletizer

High position gantry palletizer

Single Arm Palletizer

Manual Palletizer

|

||||

|

|

|

Manual

Film shrinker

Wrap Around packer

Robert Packing Machine

|

1*2

2*3

3*4

4*6

3*5

|

|

||||

|

User Ambient Conditions

|

|

Temperature:10~40℃;Humidity:No dew

|

|

|

||||

|

User Electrical Supply Specification

|

|

Voltage:380V±5%, 3phase; Frequency:50HZ±1%

|

|

|

||||

The Beer Bottling Line adopts the advanced international technology .The design is scientific and reasonable ,appearance is beautiful ,operation and maintenance are convenient ,and it is with high degree of automatization. It is the good machine for choosing by the drinking filling factory.

Washing Parts.

Filling Parts.

Filling Heads.

Adopting the way of filling by holding the necks of the bottle, plus the function of pre-cover of the centralizing cover with high precise centralization,which ensure the right seating of mouth of the bottle and filling valve,with low liquid loss.

Capping Parts.

This series of Automatic Glass Bottle Beer Filling Machine can meet the filling-sealing requirements of different sealing manners for crown cap /screw cap or others.

Adopting crowning the caps with magnetic force,which passes the torque with powerful and constant magnet,and the torque can be adjusted to meet the need of many kind of caps.

Flat Conveyor.

<2> Special lubrication system, keep products clean, health, safety

<3>Extended service life

<4>Electric eyes design keep whole line running safety and quickly

<5>Overload protection mechanism to effectively ensure the safety of the machine

Water treatment system.

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

Drink Mixing Machine.

1. suitable beverage types: Cola and lemon.

2. mixing ratio range: 3:1 - 6:1

3. CO2 content: 4 times

4. volume: CO2 consumption of about 4 M3/h

5. CO2 supply pressure: 0.8-1 Mpa

6. CO2 Purity: 99.9%

7. consumption of ethylene glycol solution: water=30M3/h

8. ethylene glycol solution pressure: 1.0Mpa

9. ethylene glycol solution inlet temperature: -2 C.

Empty Bottle Feeding Table.

The table is specially designed for the bottle up-loader and bottle collect ,or you also can prepare them yourself .

Material :Stainless steel SUS304.

Conveyor.

2.Supporting leg: 304 stainless steel pressing structure

3.Bearing housing: 304 stainless steel cage

4.With domestic brand motor speed adjustable

5.It should be designed by your factory layout

Shower Cooling Machine.

1/

Mainly for cooling and sterilization

2/

The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3/

Nozzles are manufactured using U.S. technology and spray water evenly

4/

Conveyor belt adopts Rexnor technology, flat surface with small wear

5/

Smooth and reliable operation with low energy consumption

Automatic labeling machine.

1/Heat shrink sleeve labeling machine

2/OPP Hot melt labeling machine<in picture>

3/PVC label stick labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

Bottle Packaging Machine.

1/PE film shrink wrapping machine<in picture>

2/Half-tray shrink wrapping machine

3/Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

<1> Standardized workshop of total 12,000 square meters .

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier & korea daewoo, ensure the precision of parts.

<2>International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments:

ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:

standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.

<3>The equipment will be tested and run for 24 hours before leaving the factory , to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

<4> Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<5>The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<6> Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

Delivery.

Package Type :

As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

Transport :

By sea. By train. By aircraft.