- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

10KW

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

2400X1200X2200MM

-

Processing Types:

-

SUS304 316 STEEL

-

Product name:

-

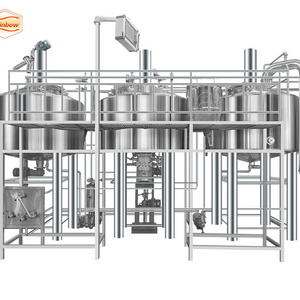

Mash Tun Beer Brewing 10hl Beer Brewery System Bar Brewery Plant

-

Material:

-

Stainless Steel 304 316L

-

Keyword:

-

Commercial Distillation System

-

Capacity:

-

50L-5000L

-

Application:

-

Craft Spirit Production Line

-

Origin:

-

CHINA

-

Control System:

-

PLC

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OKMACHINE

-

Model Number:

-

OK-B

-

Voltage:

-

380V

-

Power:

-

10KW

-

Weight:

-

5000 KG

-

Dimension(L*W*H):

-

2400X1200X2200MM

-

Processing Types:

-

SUS304 316 STEEL

-

Product name:

-

Mash Tun Beer Brewing 10hl Beer Brewery System Bar Brewery Plant

-

Material:

-

Stainless Steel 304 316L

-

Keyword:

-

Commercial Distillation System

-

Capacity:

-

50L-5000L

-

Application:

-

Craft Spirit Production Line

-

Origin:

-

CHINA

-

Control System:

-

PLC

Our service

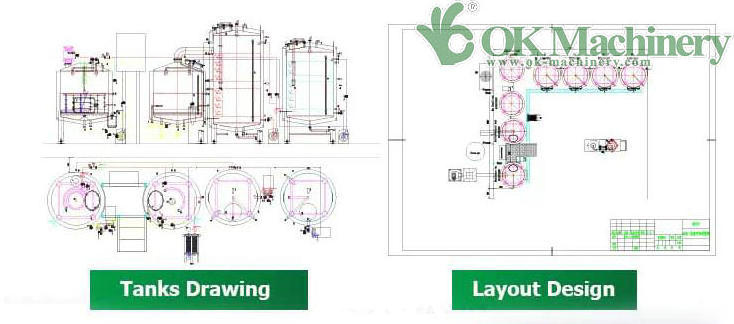

1. OKMACHINE provides a turnkey solution from project consulting, benefit analysis, space layout design, 3D rendering, production site, equipment design, manufacturing, installation, commissioning, training, and other one-stop services.

2. OKMACHINE provides installation and debugging service at a service fee (100usd) per day.

3. OKMACHINE factory marks all piping with numbers, solve any questions during your installation.

4. OKMACHINE technicians will train the brewer to produce qualified craft beer.

5. OKMACHINE provides installation and maintenance manual book, piping installing layout.

6. Sales&engineers could be keeping 24 hours online for service.

7. OKMACHINE provides a 3-year warranty on tanks sold with manufacturing defects from the factory. Micet provides a 1-year warranty on tank accessories, pumps, electronic components.

8. Any extra spare parts required, send and deliver immediately.

Product Description

Specification

|

Fermentation tank series

|

Volume in US Gallon

|

Diameter

|

Height

|

|

100l Fermentation tank

|

26US Gallon

|

640mm

|

1500mm

|

|

200l Fermentation Tank

|

53US Gallon

|

760mm

|

1800mm

|

|

300l Fermentation Tank

|

79US Gallon

|

860mm

|

2000mm

|

|

500l Fermentation Tank

|

132US Gallon

|

960mm

|

2350mm

|

|

1000l Fermentation Tank

|

264US Gallon

|

1260mm

|

2650mm

|

|

2000l Fermentation Tank

|

528US Gallon

|

1560mm

|

3150mm

|

|

3000l Fermentation Tank

|

793US Gallon

|

1800mm

|

3550mm

|

|

5000l Fermentation Tank

|

1321US Gallon

|

2000mm

|

4450mm

|

|

10000 Fermentation Tank

|

2642US Gallon

|

2200mm

|

6100mm

|

Product Advantages

1.The Mash tank is equipped with a clamped level gauge for easy observation. All the lauter tun use milled sieve plates, which have higher filtration accuracy and better effect.

2.The grains outdoor of lauter tun is equipped with a dustpan, which is convenient for grains out and cleaning. The drain outlet is separated from the discharge outlet, which is convenient for customers to discharge directly.

3.According to the customer’s brewing process, the mash system can not only meet the feeding in the boiling kettle but also meet

the feeding in the lauter tun.

4.Our mash system can realize both natural filtration and pumping filtration. The lauter tun stirring motor is equipped with a frequency converter, which can realize the step-less speed regulation. The rake motor can also be designed up and down to lift the rake.

5.To avoid too much water vapor in the mashing area, the kettle is equipped with an indoor exhaust device or outdoor exhaust device depends on customer needs.

6.Equipping with a special inline hop filter to make the wort clearer before fermenting.

7.The pump motor uses ABB or JLEM American brand, long service life, and low sound.

8.The mash tun is equipped with a grist hydrator to ensure uniform malt moistening.

9.The brewhouse piping design is equipped with a cold and hot water mixing device, thermometer, and flow meter, which can evenly mix the cold and hot water before mashing.

10.The bottom of lauter tun is equipped with a wort collection loop and an under-the-flush device.

11.Equipping with wort balance tank to check the clarity of wort and protect the sieve plate.

12.Equipping with sparge arm and double CIP cleaning loop on top of the tank.

13.Milling sieve plate, wedge-shaped gap 0.7mm, 4mm thickness, can be disassembled and cleaned, and the bottom is supported and fixed.

14.The HLT was designed with a return port, CIP cleaning port, and water inlet, which can realize the recovery and utilization of hot water between the heat exchanger.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches