- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

210 KG

-

Product name:

-

Rotary Vibrating Screen

-

Keyword:

-

Vibratory Sieve

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Color:

-

Customers' Request

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball

-

Capacity:

-

100Kg-10Tons/hour

-

Diameter:

-

400-2000mm

-

Mesh size:

-

2-500mesh

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

sanyuantang

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

According to different model

-

Weight:

-

210 KG

-

Product name:

-

Rotary Vibrating Screen

-

Keyword:

-

Vibratory Sieve

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Function:

-

Screening\separation\sorting\sieving

-

Color:

-

Customers' Request

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball

-

Capacity:

-

100Kg-10Tons/hour

-

Diameter:

-

400-2000mm

-

Mesh size:

-

2-500mesh

Product description

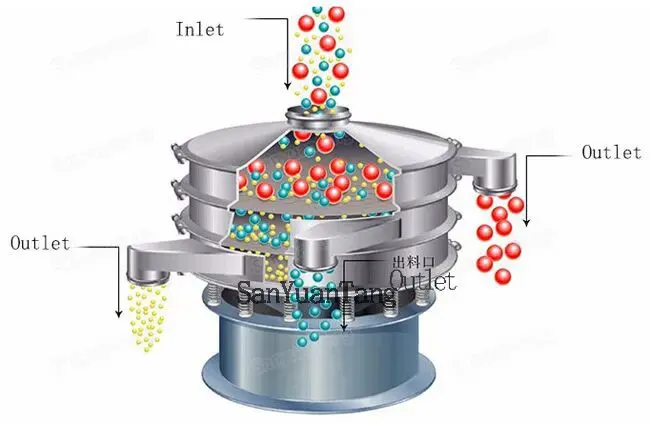

Rotary vibrating screen is a kind of sieving machine which is widely used for filtering, sieving and removing the impurity.

Rotary vibrating screen can handle the material into the precision screening or probability screening by adjust the upper and lower ends of the phase angle of the hammer so as to change the movement trajectories of materials on the screen surface.

Application field

Product details

|

Model

|

Screen Deck

|

Screen Diameter

|

Motor Power

|

Dimensions(mm)

|

Weight

|

|

SY-400

|

1

|

400mm

|

0.25KW

|

580×580×560

|

55kg

|

|

|

2

|

400mm

|

|

580×580×670

|

65kg

|

|

|

3

|

400mm

|

|

580×580×780

|

75kg

|

|

SY-600

|

1

|

600mm

|

0.55KW

|

800×800×750

|

98kg

|

|

|

2

|

600mm

|

|

4575×1546×890

|

118kg

|

|

|

3

|

600mm

|

|

4854×1549×1030

|

138kg

|

|

SY-800

|

1

|

800mm

|

0.75KW

|

900×900×750

|

158kg

|

|

|

2

|

800mm

|

|

4765×2159×890

|

196kg

|

|

|

3

|

800mm

|

|

4765×2159×1030

|

238kg

|

|

SY-1000

|

1

|

1000mm

|

1.47KW

|

1160×1160×810

|

245kg

|

|

|

2

|

1000mm

|

|

1160×1160×950

|

305kg

|

|

|

3

|

1000mm

|

|

1160×1160×1090

|

365kg

|

|

SY-1200

|

1

|

1200mm

|

1.84KW

|

1360×1360×885

|

330kg

|

|

|

2

|

1200mm

|

|

1360×1360×1050

|

408kg

|

|

|

3

|

1200mm

|

|

1360×1360×1275

|

488kg

|

|

SY-1500

|

1

|

1500mm

|

2.2KW

|

1850×1850×990

|

478kg

|

|

|

2

|

1500mm

|

|

1850×1850×1185

|

578kg

|

|

|

3

|

1500mm

|

|

1850×1850×1380

|

678kg

|

Product configuration

Frame

Machine Cover

Sieve Frame

Ultrasonic System

Motor

Base

San Yuan Tang Co., LTD

Xinxiang Sanyuantang Machine Co., Ltd., an ISO9001 certified enterprise, specializes in manufacturing series of vibrating screens and vibrating machines. We welcome both old and new customers from home and abroad visiting our company and discussing businesses.

Similar Products

FAQ

Q1:

What is the real delivery time of your factory

A1:

7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q2:

How do your after-sale service work if the product got damaged?

A2:

In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fixed cost and refund this part of cost.

(Note: Vulnerable parts do not include. If you are interested in our products, please feel free to send me an inquiry or contact any time. I will provide you with the best service and the most favorable price.

Q3:

How To Choose Suitable Model?

A3:

1. If you have ever used the screen machine, kindly please tell us its DIAMETER, LAYERS, MESH SIZES, MATERIALS.

2. If never use the machine until now, please offer us the info about material as below: 1> Material name: _____, bulk density :_____kg/m³ or ____g/cm³, and water content about _____%.

2> Capacity required___kg/h

3> How many layers?____ layers.

4>The mesh size for each layer: ____ mm, ____ mm, ____mm. Or ____ mesh, ____ mesh, ____ mesh.

5> Voltage and frequency:____V, ___HZ, 3 phase

6> Sea port name or address for shipment.

Hot Searches