Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

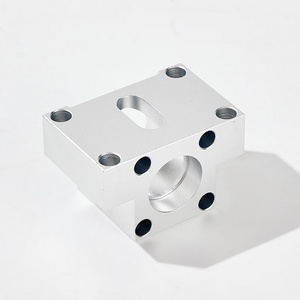

Model Number:

-

HLD-29

-

Brand Name:

-

OEM

-

Keyword:

-

cnc machining precision parts

-

Process:

-

cnc turning /cnc machining/cnc milling /lathe turning

-

Material:

-

stainless steel/aluminum/brasss

-

Surface treatment:

-

Powder coating,electroplating,oxide,anodization

-

Drawing Format:

-

STEP/3D/2D /PDF /Drawing

-

Tolerance:

-

precise cnc parts 0.01-0.02mm

-

Equipment:

-

cnc machining center/automatic lathe

-

Finish:

-

Matt/anodized/Polish

-

Application:

-

mechanical industry

-

Service:

-

Customized OEM Services

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, As your request

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

HLD-29

-

Brand Name:

-

OEM

-

Keyword:

-

cnc machining precision parts

-

Process:

-

cnc turning /cnc machining/cnc milling /lathe turning

-

Material:

-

stainless steel/aluminum/brasss

-

Surface treatment:

-

Powder coating,electroplating,oxide,anodization

-

Drawing Format:

-

STEP/3D/2D /PDF /Drawing

-

Tolerance:

-

precise cnc parts 0.01-0.02mm

-

Equipment:

-

cnc machining center/automatic lathe

-

Finish:

-

Matt/anodized/Polish

-

Application:

-

mechanical industry

-

Service:

-

Customized OEM Services

Products Description

|

Software/format

|

PRO/E, Auto CAD, Solid works, IGS, UG, CAD/CAM/CAE

|

|

|

Name

|

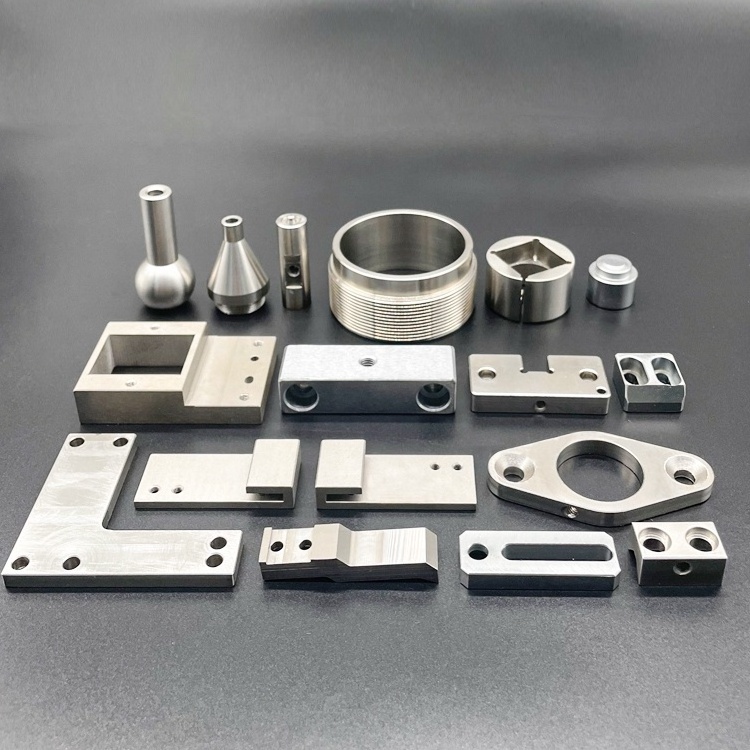

CNC Turning Machining Service Custom Precision Stainless Steel Fabrication Anodized Mechanical Parts

|

|

|

Tolerance

|

0.01~0.05mm, can customize as per request.

|

|

|

Dimension

|

Customized

|

|

|

Test equipment

|

Measurement instrument, projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin guage etc.

|

|

|

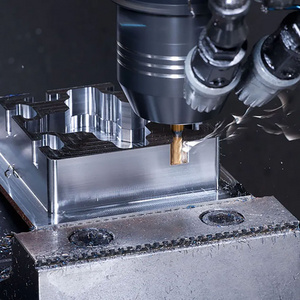

Processing

|

CNC turning, milling, drilling, auto lathe, tapping, bushing, surface treatment, anodized, casting ,injection,3D printing,etc.

|

|

|

Our Advantages

|

1.) 24 hours online service & quickly quote/delivery.

2.) 100% QC quality inspection before delivery, can provide quality

inspection form.

3.) 15+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions.

|

|

|

|

||

|

1.Main Materials

|

|

|

|

|

||||

|

Aluminum

|

Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc.

|

|

|

|

||||

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416, etc.

|

|

|

|

||||

|

Steel

|

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

|

|

|

|

||||

|

Brass

|

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

|

|

|

|

||||

|

Copper

|

C11000, C12000, C12200, C10100, etc.

|

|

|

|

||||

|

Iron

|

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

|

|

|

|

||||

|

Plastic

|

POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc

|

|

|

|

||||

|

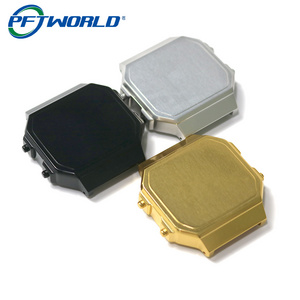

2. Surface Treatment

|

|

|

|

|

||||

|

Stainless Steel

|

Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc.

|

|

|

|

||||

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated

|

|

|

|

||||

|

Aluminum Parts

|

Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Powder Coated, Nickel Plated Etc.

|

|

|

|

||||

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving

|

|

|

|

||||

Technical Support

Shenzhen Henglongda is a professional factory at independent development and design. Our engineers are skilled at AUTO CAD, PROENGINEER, SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.

Shenzhen Henglongda is a professional factory at independent development and design. Our engineers are skilled at AUTO CAD, PROENGINEER, SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details beforethe production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality

control(IPQC)

control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC) 5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Shenzhen Henglongda Tech., Ltd is an ambitious ISO registered company, we specialized in

CNC Machining

and focusing on superior workmanship,

absolute quality

,

cleanliness

, and

lead time

. We're a firmly united team of talented and experienced engineers, machinists and technical consultants, who commit to helping solve problems relative to manufacturing precision and complex machined parts,including design, product costing, quality, assembly service, etc.

What makes Henglongda Tech different from other machining company is that Henglongda is the label of superior quality and high efficiency. We have imported much high-tech equipment during these years, for example,

4 axis CNC machining center

, which enables us to make complex and micro machine precision parts faster than ever.

Our purpose is to help millions of buyers for custom CNC machining parts to do business easily. Welcome to discuss your ideas with our technical team

>>>

Product packaging

FAQ

Q:What do I need for offering a quote?

A: Please offer us 2D or 3D drawings (conclude materials,dimension,tolerance,surface treatment or other technical requirement),quantity,application,or samples.Then we will quote the best price within 24 hours for you.

Q:How about the MOQ?

A:MOQ depends on your need ,besides,we welcome trial order before mass-production.

Q:What is the product cycle?

A:It varies a lot depending on product dimension,technical requirement and quantity.We always try to meet customer's

requirement by adjusting our workshop schedule.

Q:What kind of payment terms do you accept?

A:T/T,L/C,Escrow,paypal,western union,moneygram.

Q:Is it possible to know how is my product going on without visiting our company?

A:We will offer a detailed products schedule and send weekly reports with digital pictures and vedios which show the machining progress.

Hot Searches