- Product Details

- {{item.text}}

Quick Details

-

Form:

-

Paste

-

Flux:

-

0%-25% for flame/inductive brazing

-

Temperature:

-

1010-1175

-

Materials:

-

NiCrSiB

-

Powder:

-

200 um

-

Heating:

-

Flame, inductive, vacuum / continuous furnace

-

Application:

-

Tools, car pipes, valves

-

Density:

-

5~8

-

Color:

-

Red for Cu, Black for most of others

-

Delivery:

-

7 days

Quick Details

-

Warranty:

-

12 month

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tibright

-

Form:

-

Paste

-

Flux:

-

0%-25% for flame/inductive brazing

-

Temperature:

-

1010-1175

-

Materials:

-

NiCrSiB

-

Powder:

-

200 um

-

Heating:

-

Flame, inductive, vacuum / continuous furnace

-

Application:

-

Tools, car pipes, valves

-

Density:

-

5~8

-

Color:

-

Red for Cu, Black for most of others

-

Delivery:

-

7 days

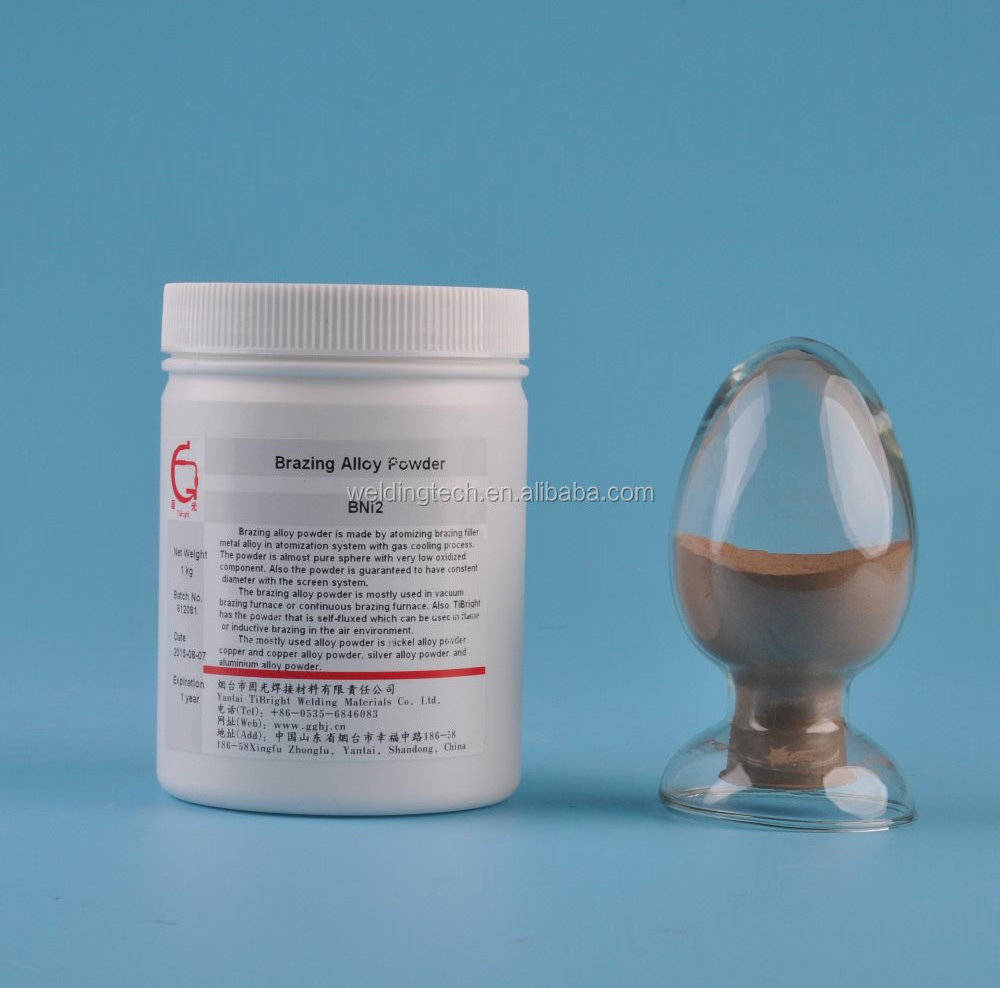

Nickel, Copper, Silver, Aluminium Brazing Filler Metal Paste

---for Flame, Inductive Vacuum and Continuous Furnace

We can supply a wide range of brazing and soldering powder and pastes. Pastes can be supplied with and without flux and with various metal content percentage. Brazing filler metal paste is widely used in vacuum and continuous furncace. Recetly, we developed the filler metal paste which can be used under air atmosphere, i.e. for flame and inductive brazing.

To select the most appropriate brazing paste, many factors have to be taken into account, such as: materials to be joined, heating method, type of atmosphere, etc.

We can also customize product for our customer.

Nickel Brazing Filler Metal Paste

Nickel brazing filler metal paste are widely used to braze diamond and carbide with steel, stainless steel for tools. also in car industry, nickel brazing filler metal paste is used to braze car pipe because of its corrosion resistence. Most nickel brazing filler metal paste are used in vacuum or continuous furnace.

|

AWS standard |

Chinese Standard

|

Tempearature |

Materials |

Form |

||||||

|

Cr |

B |

Si |

Fe |

C |

P |

Ni |

||||

|

BNi-1 |

BNi74CrSiB |

1065-1205 |

13.0-15.0 |

2.75-3.5 |

4.0-5.0 |

4.0-5.0 |

0.6-0.9 |

0.02 |

Bal. |

Powder/paste |

|

BNi-1A |

BNi75CrSiB |

1075-1205 |

13.0-15.0 |

2.75-3.5 |

4.0-5.0 |

4.0-5.0 |

0.06 |

0.02 |

Bal. |

Powder/paste |

|

BNi-2 |

BNi82CrSiB |

1010-1175 |

6.0-8.0 |

2.75-3.5 |

4.0-5.0 |

2.5-3.5 |

0.06 |

0.02 |

Bal. |

Powder/paste |

|

BNi-3 |

BNi92SiB |

1010-1175 |

N/A |

2.75-3.5 |

4.0-5.0 |

0.5 |

0.06 |

0.02 |

Bal. |

Powder/paste |

|

BNi-4 |

BNi93SiB |

1010-1175 |

N/A |

1.5-2.2 |

3.0-4.0 |

1.5 |

0.06 |

0.02 |

Bal. |

Powder/paste |

|

BNi-5 |

BNi71CrSi |

1150-1205 |

18.5-19.5 |

0.03 |

9.75-10.5 |

N/A |

0.1 |

N/A |

Bal. |

Powder/paste |

|

BNi-6 |

Ni89P |

927-1093 |

N/A |

N/A |

N/A |

N/A |

0.06 |

10-12 |

Bal. |

Powder/paste |

|

BNi-7 |

BNi76CrP10 |

927-1093 |

13.0-15.0 |

0.02 |

0.10 |

0.2 |

0.06 |

9.7-10.5 |

Bal. |

Powder/paste |

|

BNi-12 |

Ni65Cr25P10 |

980-1095 |

24.0-26.0 |

0.02 |

0.1 |

0.2 |

0.06 |

9.0-11.0 |

Bal. |

Powder/paste |

|

BNi-152 |

Ni63Cr29P4Si |

1050-1121 |

28.0-30.0 |

N/A |

4.0 |

N/A |

N/A |

4.0 |

Bal. |

Powder/paste |

Copper Brazing Filler Metal Paste

| Material | Temperature | Application | Color |

| Cu 99.9% | 1100 C | Furnace heating for steel, stainless steel. | Red |

| CuZn | 850C~900C | Flame, inductive, continuous furnace heating for steel, copper diamond, carbide. | Black |

| CuP | 650C~850C | Flame, inductive, vacuum, continuous furnace heating for steel, copper. | Black |

| Bronze | Special occasions | Black |

Silver Brazing Filler Metal Paste

| code | Composition% | metling range | standard | ||||

| Ag | Cu | Zn | Sn | Si | °c | EN1044 | |

| Ag45 | 45 | 30 | 25 | 677-743 | |||

| Ag35 | 35 | 32 | 33 | 680-730 | |||

| Ag30 | 30 | 38 | 32 | 690-760 | AG204 | ||

| Ag25 | 25 | 40 | 35 | 690-800 | AG205 | ||

Aluminium Brazing Filler Metal

| Filler metal | Temperature | Color |

| AlSi12, 4047 | 570 C | Black |

| AlSiCu | 480~550 C | Black |

| Zn98Al | 450C | Black |

| ZnSnCu | 380 C | Black |

50grm per pack, 100grm per pack, 1 kg per can, 5kg per can

Yantai Tibright Welding Materials Co. Ltd. is a manufacturer of all kinds brazing materials, equipments, and utensils. The company has started since 2000. We are the most professional researcher and developer of brazing materials in China. We have accumulated dozens of different product technology and sunsequenly abundant product pool. We are also glad to customize product for specific costomers.

When choose from our product pool, please check out our recommended product list and if you have any questions, please let us know and we will try our best to satisfy your inquiry. Some thime we need our customers to try different sample to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your to-be-brazed parts.

2. Heat method. (eg. flame, induction, vacuum furnace etc. )

3. Dimensions of your parts, photoes or graphes are preferred. (Different dimensions requires different procesure.)

4. If available, what kind of brazing materials are currently being used.

5. What industry you are in. (help us refer to similar samples.)

One headlight of our service is that we provide costomized product specially designed for specific costomer. We have a lot of successful cases in which the customer had the product suitable for their own procedure, environment and operation habits perfectly.

We also provide entire brazing solution for customers to solve all the problems related to brazing process. For those brazing parts, materials and dimensions which are hard to braze we can come up with a solution after enough research for our customers.

About sixty percent of our equipments are designed and crafted in our own machine workshop. We also produce the service of special designed brazing tools and machines. We have the ability to reserch product together with our customers.