- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

LIHUA

-

Model Number:

-

20-180MESH

-

Usage:

-

For Welding

-

Material:

-

carbide Carbide Alloy Particles

-

Product name:

-

carbide grain/Carbide Grits/tungsten granules

-

color:

-

black

-

size:

-

5-170mesh

-

certificaton:

-

ISO2008

-

density:

-

14.8g/cm3

-

hardness:

-

89.5HRA

-

Packaging:

-

Iron drums

-

Characteristic:

-

Long life time

-

Application:

-

Wear Resistance ,hardfacing ,welding

Quick Details

-

Type:

-

blasting media, Welding

-

Abrasive Grain Sizes:

-

1-170 mesh crushed carbide grits

-

Warranty:

-

None

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

LIHUA

-

Model Number:

-

20-180MESH

-

Usage:

-

For Welding

-

Material:

-

carbide Carbide Alloy Particles

-

Product name:

-

carbide grain/Carbide Grits/tungsten granules

-

color:

-

black

-

size:

-

5-170mesh

-

certificaton:

-

ISO2008

-

density:

-

14.8g/cm3

-

hardness:

-

89.5HRA

-

Packaging:

-

Iron drums

-

Characteristic:

-

Long life time

-

Application:

-

Wear Resistance ,hardfacing ,welding

Product Description

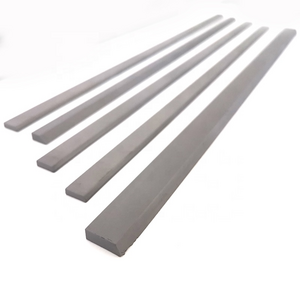

Tungsten Carbide Black Crashed Grits

Tungsten carbide grits also called tungsten grits,carbide grits,it is used to welding or solder onto a steel body, to increase thewear resistance properties. For example, if a steel cutter can cut 24 hours without grits, it will cut 240 hours after with the tungsten carbide grits.

Application

The tungsten carbide grits is suitable for hard facing material.

1 mesh to 12 mesh: used for wear-resistance electrode and mace electrode;

10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

The tungsten carbide grits is suitable for hard facing material.

1 mesh to 12 mesh: used for wear-resistance electrode and mace electrode;

10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

1) Ceramic, metal lapping, and polishing applications

2) Slicing of silicon carbide wafers

3) Rock and stone polishing and engraving

4) Slicing, lapping,and polishing glass and germanium wafers

5) Lapping of piston rings and gears

6) Grinding of nonferrous materials

7) Finishing tough and hard materials

8) Bonded abrasive tool applications

9) Glass etching and glass carving industries

2) Slicing of silicon carbide wafers

3) Rock and stone polishing and engraving

4) Slicing, lapping,and polishing glass and germanium wafers

5) Lapping of piston rings and gears

6) Grinding of nonferrous materials

7) Finishing tough and hard materials

8) Bonded abrasive tool applications

9) Glass etching and glass carving industries

Advantage

1) High thermal conductivity rating of 100 W/m-k

2) Extremely hard : Mohs 9.1 or 2550 Knoop. Harder than aluminum oxide

3) Blocky grain, will splinter as it breaks down, fast cutting speeds,great for recycling

4) High strength at elevated temperatures

5) Great for glass frosting & engraving,stone carving & etching, rock tumbling

6) Grades 16 through 1500 available

1) High thermal conductivity rating of 100 W/m-k

2) Extremely hard : Mohs 9.1 or 2550 Knoop. Harder than aluminum oxide

3) Blocky grain, will splinter as it breaks down, fast cutting speeds,great for recycling

4) High strength at elevated temperatures

5) Great for glass frosting & engraving,stone carving & etching, rock tumbling

6) Grades 16 through 1500 available

Recommend Products

Hot Searches

![[ AiFan Dental ] Best Price FG High Speed Dental lab Tungsten Carbide Burs](https://cdn.bestsuppliers.com/seo_products_img/aifandental/bc00aabadb0636ebbdd9068494ac2120.jpg!/rotate/180/sq/300)