- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

U Zone

-

Place of Origin:

-

Zhejiang, China

-

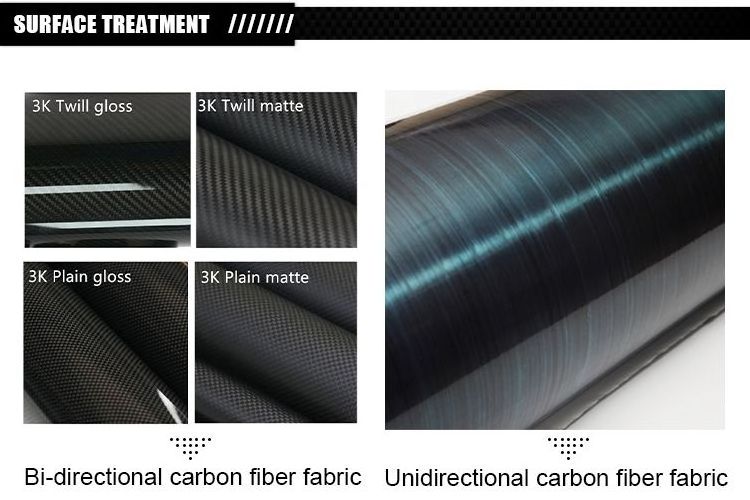

Surface treatment:

-

Glossy/Matte clear coating

-

Weave:

-

Plain/Twill weave

-

Service:

-

Carbon Fiber CNC Cutting, machining and Molded Products

-

Physical Property:

-

High Strength Low Weight

-

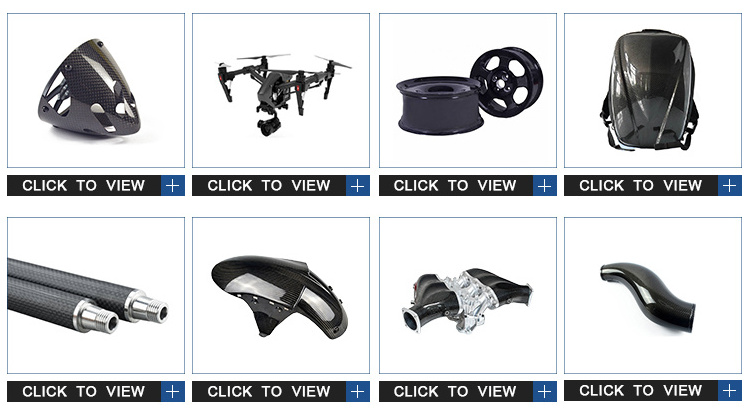

Application Area:

-

Auto car/ aircraft/ medical/ motorcycle/ bike/ and so on

Quick Details

-

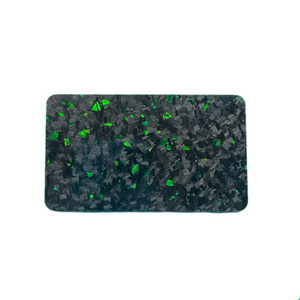

Color:

-

Red, Blue, Black

-

Weight:

-

Customized, Customized

-

Model Number:

-

Customized

-

Brand Name:

-

U Zone

-

Place of Origin:

-

Zhejiang, China

-

Surface treatment:

-

Glossy/Matte clear coating

-

Weave:

-

Plain/Twill weave

-

Service:

-

Carbon Fiber CNC Cutting, machining and Molded Products

-

Physical Property:

-

High Strength Low Weight

-

Application Area:

-

Auto car/ aircraft/ medical/ motorcycle/ bike/ and so on

U Zone Factory Customized Light Weight Carbon Fiber Air Intake For New Energy Vehicles Forged Fiberglass Auto Parts

|

Product Name

|

U Zone Factory Customized Light Weight Carbon Fiber Air Intake For New Energy Vehicles Forged Fiberglass Auto Parts

|

|

Tolerance

|

+/-0.05mm~5mm

|

|

Surface Roughness

|

Ra 0.6-3.2

|

|

Terms of Trade

|

EXW, FOB, CIF,D2D

|

|

Terms of Payment

|

T/T, Western Union, L/C, Paypal

|

|

Packing

|

Eco-packaging: EPE Foam, Carton, Wooden boxes, and other tailor-made packing per customer's requirement

|

Custom Carbon Fiber Parts:

3K Twill Gloss/ 3K Twill Matte/ 3K Plain Gloss/ 3K Plain Matte.

1. Mould Pressing for Custom Carbon Fiber

:

The method of adding a certain amount of prepreg into the metal pair mold and curing by heating and pressure. The main advantages of molding molding process are high production efficiency, easy to achieve professional and automatic production and product size precision is high, good repeatabilityand can be formed a complex structure of products, can be mass productionthe price is relatively low.

2. Autoclave Molding:

The composite billet composed of single layer prepreg material is placed in a hot pressing tank and the curing process is completed under a certain temperature and pressure. Autoclave molding is a special pressure vessel which can withstand and control a certain range of temperature and pressure.

3. Hand Lay-up Process:

The solidification process of hand paste process can be carried out at room temperature, without special mechanical equipmentlow cost not limited by the shape and size of the products, easy to operate, especially suitable for the production of small number of products, complex modeling.

4. Vacuum Diversion for Carbon Fiber Custom.

The carbon fiber reinforced material and resin are manually laid into the prefabricated molding mold in accordance with the fiber direction and order designed by the product itself. After the predetermined layer thickness is realizedthe product is covered with a vacuum bag, pressurized by vacuum pumpingand cured by heating. After that the carbon fiber products are demoulded and processed by the appearance. Compared with the hand-laying processthe compactness of the product is enhanced in the pressure curing process and the porosity is reduced to improve the quality of the product.

U Zone Factory Customized Light Weight Carbon Fiber Air Intake For New Energy Vehicles Forged Fiberglass Auto Parts

Hot Searches