- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 3-phase 5Hz

-

Dimension(L*W*H):

-

750*1040*1170mm

-

Power (kW):

-

26

-

Weight (KG):

-

290 KG

-

name:

-

Polyurea Spraying Machine

-

heating power:

-

22KW

-

Transformer power:

-

3.5KW

-

drive mode:

-

hydraulic drive

-

Unilateral pressure:

-

36MPa

-

raw material ratio:

-

1:1

-

raw material output:

-

2-10KG/Min

-

insulated pipes:

-

Support 105M

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FINEWORKCNC

-

Machine Type:

-

Injection machine

-

Voltage:

-

380V 3-phase 5Hz

-

Dimension(L*W*H):

-

750*1040*1170mm

-

Power (kW):

-

26

-

Weight (KG):

-

290 KG

-

name:

-

Polyurea Spraying Machine

-

heating power:

-

22KW

-

Transformer power:

-

3.5KW

-

drive mode:

-

hydraulic drive

-

Unilateral pressure:

-

36MPa

-

raw material ratio:

-

1:1

-

raw material output:

-

2-10KG/Min

-

insulated pipes:

-

Support 105M

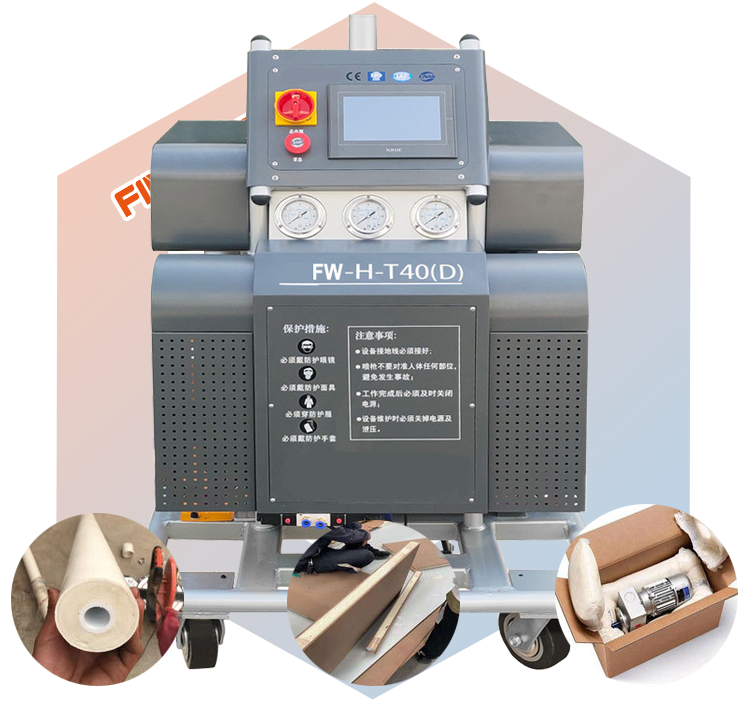

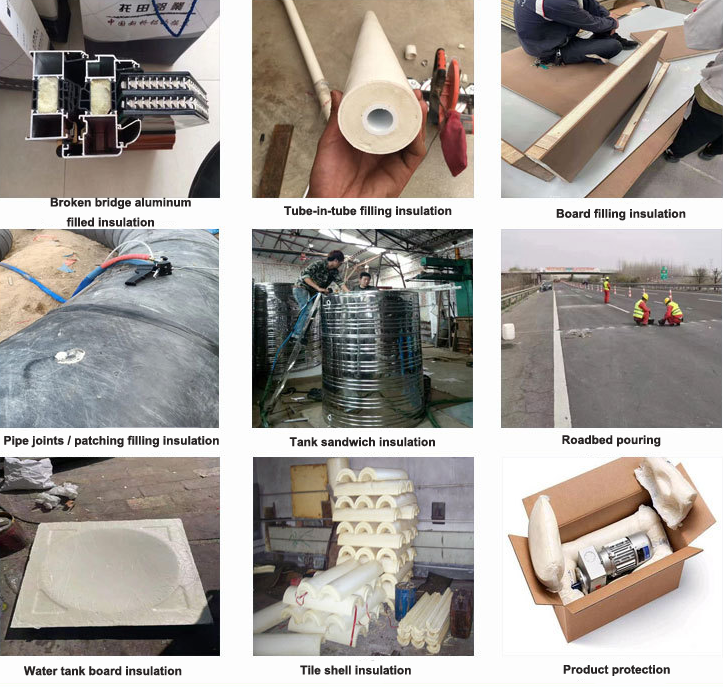

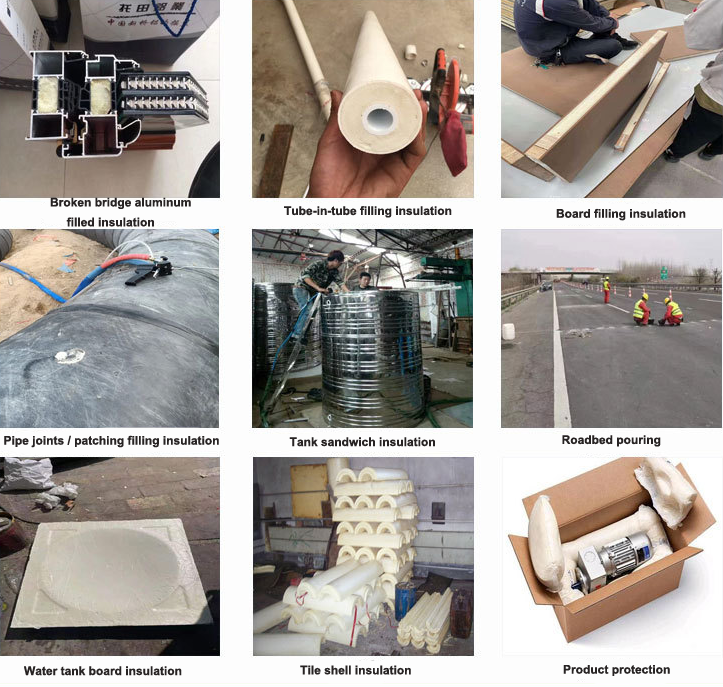

Application Sample

Widely used in industrial maintenance, tunnels, subways, roadbed waterproofing,foam film and television props production,Pipe anticorrosion, roof waterproof,basement waterproof, wear-resistant lining, external wall insulation, etc.

It does the job of spraying the two-component polyurethane raw material in liquid form by mixing it with a certain temperature and pressure. Polyurethane, which is mixed and sprayed under certain heat and pressure, quickly adheres to the surface on which it is applied, swells and reaches the final foam form. It can be said that the obtained polyurethane foam is the highest point reached in the world in thermal insulation.

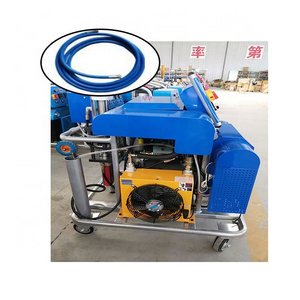

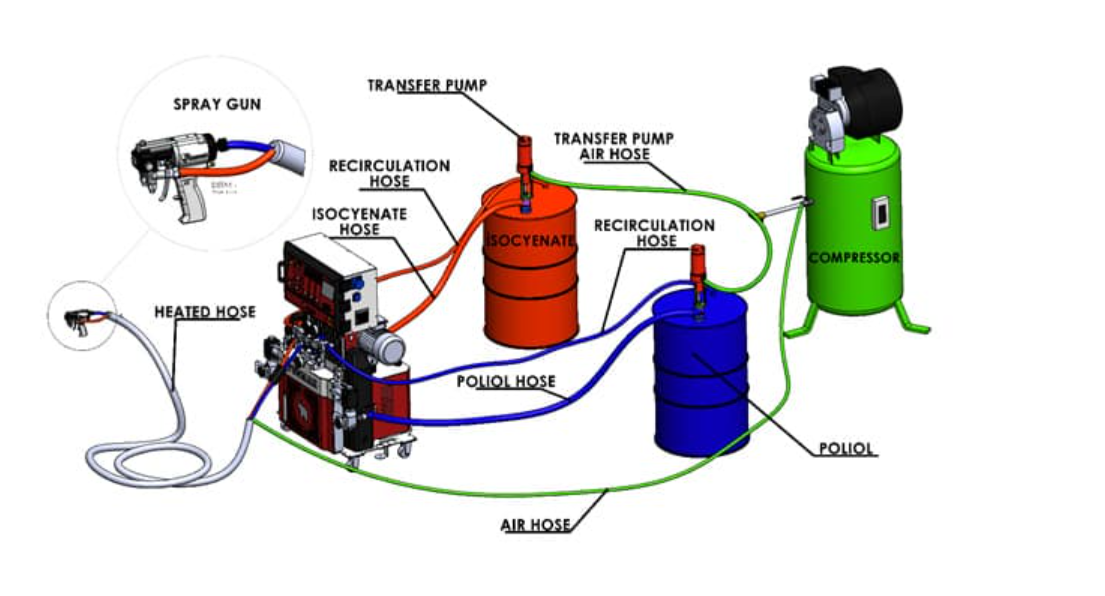

It would be more accurate to define spray foam machines as a machine set. Because this set consists of a high pressure spray foam machine, an air source compressor, two transfer pumps used to transfer the raw material from the barrels, a heated hose specially designed to maintain the temperature of the heated raw material, and a spray gun, which is the point where the mixture is made.

As a working principle, machine to spray foam insulation function as a part of the set. First, the raw materials are transferred to the spray foam insulation machine by means of 2 separate pumps, the spray foam machine preheaters and the hydraulic pump ensure that the raw materials reach the appropriate consistency in terms of required heat and pressure.

Then, the liquid polyurethane raw material, which has reached the required temperature, is delivered to the gun in high pressure through the specially designed heated hose. In this whole process, the two components of the polyurethane are processed without mixing with each other. In the polyurethane gun, which is the last point of the process, these two components are mixed and sprayed under high pressure.

Finally, it should be noted that a compressor with the required power for the operation of the transfer pumps and the cleaning of the spray gun at the moment the spraying stops is a part of the set.

The following diagram shows the general view of a spray foam machine set.

Specification

|

name

|

Polyurethane injection machine

|

Transformer power

|

1KW

|

|

model

|

FW-H-T40D

|

Drive mode

|

Hydraulic drive

|

|

power supply

|

380V three-phase 50HZ

|

Output pressure

|

36MPa

|

|

total power

|

23.5KW

|

Raw material ratio

|

1:1

|

|

heating power

|

19.5kW

|

Raw material output

|

2~12kg/min

|

Factory real shots

Certifications

Packing & Delivery

Payment:

1. T/T

*We accept T/T , you can pay 30% in advance, 70% before delivery.

*The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the

testing video.

*After you agree, please finish the balance. Finally. we arrange the delive

2. Trade Assurance

Delivery:

*Outside package: Standard marine export plywood case .

*Inner package: Stretch film and plastic film for humidity .

*To better ensure the safety of your goods, we can package according to your requests.

1. T/T

*We accept T/T , you can pay 30% in advance, 70% before delivery.

*The machine will be produced after received your deposit.after the machine is ready, we will show you the machine photos and the

testing video.

*After you agree, please finish the balance. Finally. we arrange the delive

2. Trade Assurance

Delivery:

*Outside package: Standard marine export plywood case .

*Inner package: Stretch film and plastic film for humidity .

*To better ensure the safety of your goods, we can package according to your requests.

FAQ

1. W

ho are we?

Re: We are based in Shandong, China, start from 2016,sell to Domestic Market(50.00%),North America(15.00%),South America(15.00%) ,North Africa(5.00%), Middle East(5.00%), Europe(10.00%).

2. H ow can we guarantee quality?

Re: Always a pre-production sample before mass production;Always final Inspection before shipment.

3. W hat can you buy from us?

Re: foam machine,spray machine,polyurea machine,pu machine .

4. W hy should you buy from us not from other suppliers?

Re: The company has passed high-tech and ISO9001 international quality system certification; its products have passed EU CE certification; it has more than 50 national patents, with advanced technology and quality assurance.

5. W hat services can we provide?

Re: Accepted Delivery Terms: fob ,cif ,ddu and ddp Accepted Payment Currency: usd and euro Accepted Payment Type: TT

6. Do we have a discount if buy more?

Re: We have favorable prices for agents. Welcome you to become our long-term business partner.

Re: We are based in Shandong, China, start from 2016,sell to Domestic Market(50.00%),North America(15.00%),South America(15.00%) ,North Africa(5.00%), Middle East(5.00%), Europe(10.00%).

2. H ow can we guarantee quality?

Re: Always a pre-production sample before mass production;Always final Inspection before shipment.

3. W hat can you buy from us?

Re: foam machine,spray machine,polyurea machine,pu machine .

4. W hy should you buy from us not from other suppliers?

Re: The company has passed high-tech and ISO9001 international quality system certification; its products have passed EU CE certification; it has more than 50 national patents, with advanced technology and quality assurance.

5. W hat services can we provide?

Re: Accepted Delivery Terms: fob ,cif ,ddu and ddp Accepted Payment Currency: usd and euro Accepted Payment Type: TT

6. Do we have a discount if buy more?

Re: We have favorable prices for agents. Welcome you to become our long-term business partner.

Hot Searches