- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

1 - 6000

-

Spindle Taper:

-

BT50

-

Positioning Accuracy (mm):

-

0.01

-

Repeatability (X/Y/Z) (mm):

-

±0.005

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JZ

-

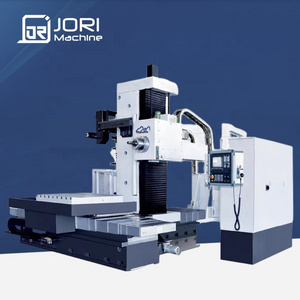

Model Number:

-

XK714

-

Table Travel (mm):

-

650*400*500

-

Year:

-

2023

-

Voltage:

-

220

-

Dimension(L*W*H):

-

650*400*500

-

Weight (KG):

-

3200

-

Max. Table Load(kg):

-

500 kg

-

Product name:

-

Homemade mini cnc lathe machine,used mini cnc milling machine

-

Machine Type:

-

XK Series CNC Milling Machine

-

Worktable T-grooves(mm):

-

3~18

-

Distance between Spindle & Worktable(mm):

-

125-625

-

Worktable Loading Capacity(mm):

-

500

-

Feeding Rate(mm/min):

-

1-5000

-

Precision:

-

High Precision

-

Main Features:

-

High reliability and excellent stability

-

Certification:

-

CE

-

Power (kW):

-

5.5/7.5

Quick Details

-

Table Travel (X) (mm):

-

650

-

Table Travel (Y) (mm):

-

400

-

Table Travel (Z) (mm):

-

500

-

Range of Spindle Speed(r.p.m):

-

1 - 6000

-

Spindle Taper:

-

BT50

-

Positioning Accuracy (mm):

-

0.01

-

Repeatability (X/Y/Z) (mm):

-

±0.005

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JZ

-

Model Number:

-

XK714

-

Table Travel (mm):

-

650*400*500

-

Year:

-

2023

-

Voltage:

-

220

-

Dimension(L*W*H):

-

650*400*500

-

Weight (KG):

-

3200

-

Max. Table Load(kg):

-

500 kg

-

Product name:

-

Homemade mini cnc lathe machine,used mini cnc milling machine

-

Machine Type:

-

XK Series CNC Milling Machine

-

Worktable T-grooves(mm):

-

3~18

-

Distance between Spindle & Worktable(mm):

-

125-625

-

Worktable Loading Capacity(mm):

-

500

-

Feeding Rate(mm/min):

-

1-5000

-

Precision:

-

High Precision

-

Main Features:

-

High reliability and excellent stability

-

Certification:

-

CE

-

Power (kW):

-

5.5/7.5

| Item | XK714 | XK715 | XK716 | XK717 | XK718 | XK719 |

| Worktable Size(mm) | 400×840 | 500×1050 | 600×1300 | 710×1400 | 800×1700 | 900×2000 |

| Worktable T-grooves(mm) | 3~18 | 3~18 | 5~18 | 5~18 | 5~22 | 5~22 |

| Travel(X,Y,Z)(mm) | 650×400×500 | 800×500×550 | 1000×600×600 | 1300×700×650 | 1500×800×700 | 1800×900×800 |

| Distance between Spindle & Worktable(mm) | 125-625 | 150-700 | 180-780 | 150-800 | 170-870 | 160-960 |

| Distance between Spindle Center & Z-axis Guidewheel Surface(mm) | 495 | 550 | 600 | 785 | 800 | 950 |

| Taper of Spindle | BT40 | BT40 | BT40 | BT50 | BT50 | BT50 |

| Max.RPM of Spindle(rpm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Motor Power of Spindle(kw) | 5.5/7.5 | 5.5/7.5 | 9/11 | 15 | 15 | 15 |

|

Feeding Rate (mm/min) |

1-5000 | 1-5000 | 1-5000 | 1-5000 | 1-5000 | 1-5000 |

| Positioning Accuracy(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Repeated Positioning Accuracy(mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Machine Weight(kg) | 3200 | 4500 | 7000 | 11200 | 13500 | 14000 |

|

Overall Dimension (mm) |

2450×2200 ×2660 |

2700×2200 ×2660 |

3400×2250× 2800 |

4000×2300× 2900 |

4420×2350× 3200 |

4450×2400× 3200 |

| Worktable Loading Capacity(mm) | 500 | 600 | 800 | 1000 | 1500 | 1600 |

| Homepage | Get back to homepage! | Price | Get the latest price here! | |||

Introduction

The CNC milling machine has the following advantages:

- Good rigidity, high precision, low noise, reasonable price and easy to operate and maintain.

- It can automatically mill planes, grooves, inclined planes and various complex curved surfaces and drilling, reaming, etc.

- The machine tool has a large range of applications, wide applicability and superior performance.

- It is especially suitable for mold processing.

Main Features

- High reliability and excellent stability

- German Siemens or Japanese Fanuc or Mitsubishi NC system

- three-axis linkage or four-axis linkage

- Imported bearing

- Imported coupling

- High-quality resin sand cast parts

- Taiwan made spindle, unclamping cylinder, precision ball screw and locking nut

- Part programming

- Error compensation

- Drilling and milling processing functions

Warranty period: one year

During warranty period, if you have any parts broken because of qulity problem, we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact with us, we will supply our best service to you as usual.

1.Technical support online service provided .

2.Technical files service provided.

3.Machine operation video provided

4.On-site training service provided.

5.Spare parts replacement and repair service provided.

6.All of the questions will be replied within 24 hours