Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAIVI-plastic machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20m

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plastic processed:

-

PE PP PVC

-

Screw design:

-

double screw

-

Max output:

-

400kg/h

-

Max power:

-

110kw

-

Motor:

-

SIEMENS

-

Shipping method:

-

Ocean shipping

-

Color:

-

Selectable

-

Certificate:

-

CE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAIVI-plastic machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20m

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plastic processed:

-

PE PP PVC

-

Screw design:

-

double screw

-

Max output:

-

400kg/h

-

Max power:

-

110kw

-

Motor:

-

SIEMENS

-

Shipping method:

-

Ocean shipping

-

Color:

-

Selectable

-

Certificate:

-

CE

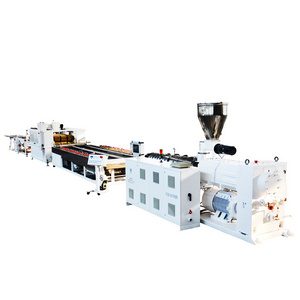

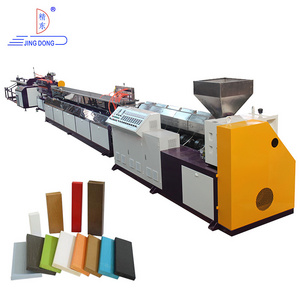

best price production line wood plastic composite / wpc profile making machine

Description of production line wood plastic composite:

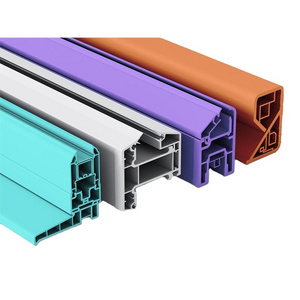

Our company successfully developed the PVC /PE/PP wood plastic foamed plate production line possess the advantages of wood and plastic, It not only has the appearance of nature wood, and also gets rid of the defaults of nature wood.

It has the same process ability of wood, can use wood tools to saw, plane, ingot and the nail effect is better than regular wood material.

The product has the same physical mechanical ability as rigid wood and its durable ability is better than regular wood material; wood plastic and its products is anti-corrosion, anti-acid, anti-alkali, water-proofed, moth-proofed, anti-bacteria, anti-aging, anti-static and flame-resistance.

Process Flow of production line wood plastic composite:

Raw material+wood power+Additive→Mixing → Granulating → Conical twin-screw extruder → Profile extrusion mould → Cool molding die → Vacuum calibration support → Belt haul-off → Cutter → Rack → Finished product inspecting& packing

Advantages of production line wood plastic composite :

1) Used to produce plastic-wood compound materials, special shape materials, plate materials, and floor or wall panels

2) Arrangement: Extruding machine, vacuum shape fitting table, hauling off and cutting machine unit, stacking frame

3) Uses RKC from Japan to control the whole line

4) Easy to operate, works steadily

5) Uses kinds of moulds to produce large range of materials

6) Widely used

Technical Parameters of production line wood plastic composite:

|

Extruder model |

SJZ55/110M |

SJZ65/132M |

SJZ80/156M |

SJZ92/188M |

||

|

Main motor powerkw |

22 |

37 |

55 |

110 |

||

|

Auxiliary equipment |

YF240S |

YF240A |

YF300A |

YF600 |

YF900 |

YF1200 |

|

Production widthmm |

Max240 |

Max240 |

Max300 |

Max600 |

Max900 |

Max1200 |

|

Vacuum pumpkw |

2×5.5 |

4×5.5 |

4×5.5 |

4×5.5 |

1×7.5 |

1×7.5 |

|

2×11 |

2×11 |

|||||

|

Water pumpkw |

1.5 |

4 |

4 |

7.5 |

7.5 |

7.5 |

|

Hauling speed |

0-5 |

0-5 |

0-5 |

0-3 |

0-2.5 |

0-2.5 |

|

Auxiliary equipment power |

22 |

35 |

35 |

44 |

52 |

62 |

|

Output kg/h |

70 |

120 |

120 |

180 |

400 |

400 |

Pictures of production line wood plastic composite:

Exhibition Show:

Shipping Show:

If you want more information about production line wood plastic composite,

please contact us, thanks!

Our company is near Shanghai, about 130km . Welcome to our factory anytime.

Whatsapp:86-13222233923