- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

3KW

-

Dimension(L*W*H):

-

2800*1400*1700mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

small egg tray manufacturing machine

-

Capacity:

-

1000pcs/h

-

Moulds:

-

3 chucks

-

Raw materia:

-

waster paper

-

Total Power:

-

35kw

-

Paper consumptiong:

-

75kg.h

-

workers:

-

3-5 people

-

Dryer:

-

SunNy drying

-

Application:

-

Small businiss,family business

-

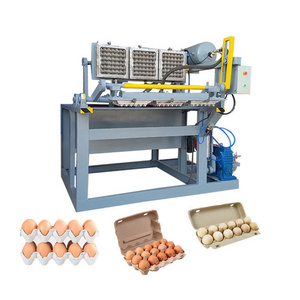

Finished Products:

-

paper egg tray, shoe tree, fruit tray,industrial packaging

Quick Details

-

Production Capacity:

-

200sets/year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zengtuo

-

Voltage:

-

220V/380V

-

Power:

-

3KW

-

Dimension(L*W*H):

-

2800*1400*1700mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2024

-

Name:

-

small egg tray manufacturing machine

-

Capacity:

-

1000pcs/h

-

Moulds:

-

3 chucks

-

Raw materia:

-

waster paper

-

Total Power:

-

35kw

-

Paper consumptiong:

-

75kg.h

-

workers:

-

3-5 people

-

Dryer:

-

SunNy drying

-

Application:

-

Small businiss,family business

-

Finished Products:

-

paper egg tray, shoe tree, fruit tray,industrial packaging

Small factory machine paper production machinery hebei egg tray machine factory

Brife Introduction

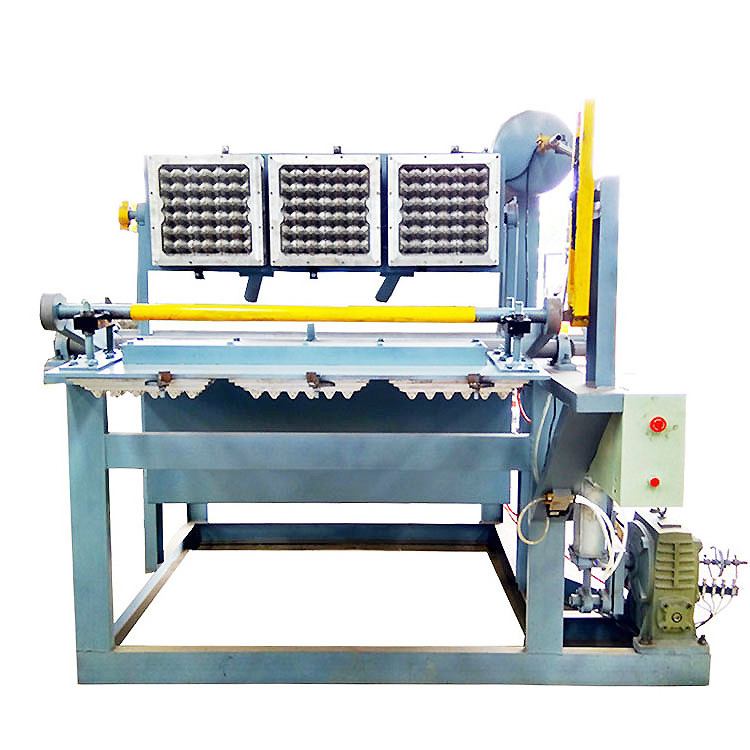

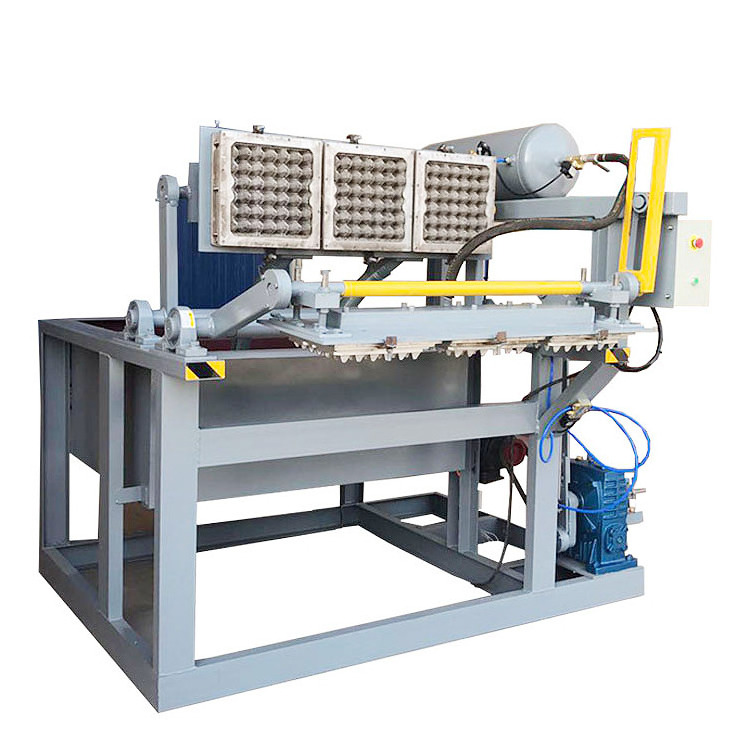

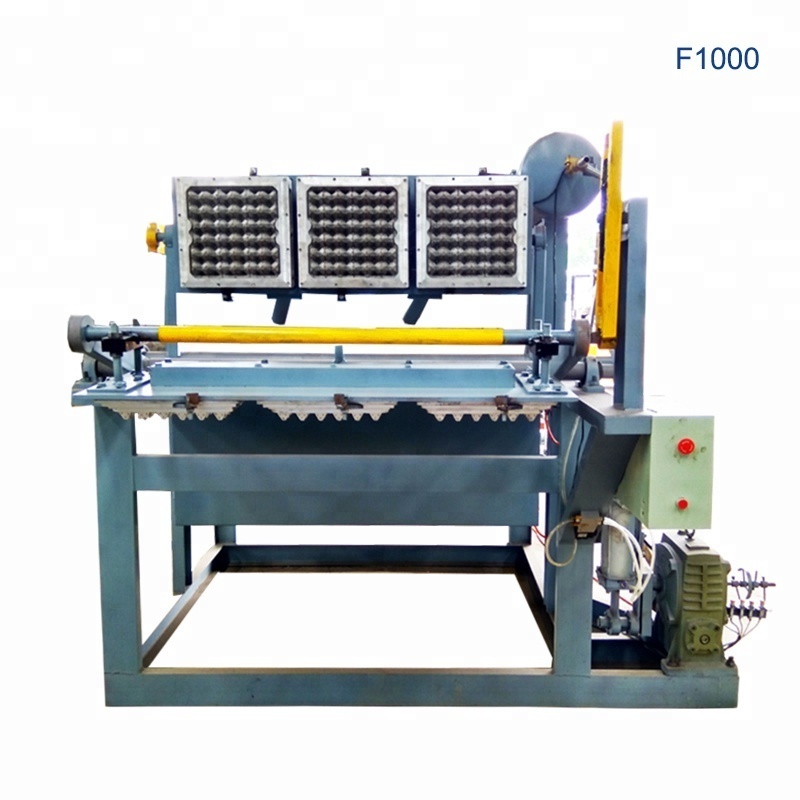

1. Model : F1000 Egg Tray Machine

2. Capacity: 1000 pcs/ hr (30 eggs tray)

3. This equipment is the 1-sided automatic rotary Molding machine, 3 chunks mould per side,total 3 chunks egg tray mould. The mould can be customized as required, plastic mould and aluminum mould are available.

4. It is applicable to the small production of all kinds of paper tray as required, such as such as egg tray, egg box, shoes tree etc.

|

Model

|

F1000 Small egg tray machine

|

|

|

||

|

Type

|

1-sides rotary making machine

|

|

|

||

|

Drying method

|

Dry the egg tray by natrual sun and wind

|

|

|

||

|

Capacity

|

1000 pcs/h

|

|

|

||

|

Votage

|

220v/380v/440v, or as required

|

|

|

||

|

Total Power

|

33kw

|

|

|

||

|

Paper consumption

|

85kg/h

|

|

|

||

|

Water consumption

|

260kg/h

|

|

|

||

|

Production line Space

|

10m*10m

|

|

|

||

|

Container

|

1*20 GP

|

|

|

||

|

Delivery time

|

15 days

|

|

|

||

1.Egg Tray Machine (a kind of pulp molding machine) uses all kinds of waste paper as raw material to produce different kinds of pulp trays products, such as egg tray, egg box, shoes tree etc

2. We have different types mould machine for choosing according to market requirements.

1.The whole production line include pulp making system , egg tray molding system , egg tray drying system , egg tray packing system

* Packing detail: The egg tray machine are nude packing or Packed in wooden case as request.

* Shipping detail: Usually we deliver the small egg tray machine within 20 days, 60 days for big production line.

1. Company Info.

We are a professional factory with 25 Years experiences on manufacture various Kinds of Egg Tray Machine, 3x4 Series, 4x4 Series, 4x8 Series, 4x12 Series, 5x8 Series, 5x12 Series, F1000 Series, F1500 Series. We produce the whole system including molding machine, pulp machines, dryer.The capacity is variety from 1000 pcs per hour to 6000 pcs per hour. Every year we produce and sell 200 sets egg tray machine to world 80 countries.

2.Visited Client s

Our egg tray machine factory located in Zhengding Town, Shijiazhuang City, Hebei Province. The nearest airport is Beijing Capital International Airport and Shijiazhuang Airport, We welcome your visit.

3.Overseas Installation

There are more than 12 engineers in our factory, they install egg tray machine overseas all year round. So we can make sure install the project in time. We have installed in Saudi Arabia, Egypt, Mali, Algeria, Angola, Cote d'Ivoire UZ, Kazakhstan, Pakistan, Nepal, Burma, Bangladesh, Philippines, Indonesia and so on.

Pre-sale service

* Reply within 24 hours by phone or email.

*As required, we will design low cost, low consumption, high efficient egg tray production line.

* Free design for production plant.

*Finish the machine within 25 working days after get the 30% deposit, deliver within 5 days after get 70% balance.

After-sale service

* When the machine arrived the destination, as the time require to install, we will send the engineer within 1 month.

*The engineer is responsible for installing the production line, and training the worker freely.

* Within 1 year warranty period, except the quick-wear parts, If there is any problems with the machines , we will free repair ( we will pay the engineer ticket and salary).

* After 1 year warranty period, as require, we will free repair. The air ticket is paid by buyer.

* lifelong technical support service.

1.What kinds of machines do you produce?

We produce

(1)pulp moulding machines,egg tray machines,egg packing machines,egg box/cartonmachines, fruit tray machines,industrial machines,seeding tray machines .and thewhole production line etc.

(2)all kinds of moulds ,such as egg tray moulds, egg box/carton moulds, fruit tray moulds,seeding tray moulds,industrial moulds etc.

(3)drying line

2.What capacity per hour do you offer ?

Our machines' capacity is from 1000pcs/hr to 6000pcs/hr.

3.What is the raw material of the paper egg tray production line?

Generally, waste office paper,newspaper,old magazine, carton board and other kinds of waste paper material. We can also make use of waste pulp from paper machine factory.

4.Do your products come with a warranty ?

Yes , we have one year warranty according the international practice.

5.Can I customize this kind of product from your factory?

Yes ,we offer custom-made service to our customers, you need to provide us some samples,such as photos,dimensions etc.

6.Can you give me a low price?

Yes,we are the manufacturer, at the same moment we guarantee the quality,we will give you a lower price.

7.How to install?

The seller dispatches engineers to buyer's factory. Buyer should help installation. Seller is responsible for installation, testing and training for 30 days, the buyer should insure the safety of the engineers.

|

Click the model to learn more specification

|

|

|

|

|

||||

|

Model

|

Moulds

|

Capacity

|

Suggest drying method

|

Total Power

|

||||

|

3 Chunks

|

1000pcs/h

|

Without dryer, drying by natural

|

34kw

|

|||||

|

|

|

|

Brick oven dryer or metallic dryer

|

59kw

|

||||

|

4 Chunks

|

1500 pcs/h

|

Brick oven dryer or metallic drye

|

62kw

|

|||||

|

12 Chunks

|

2000-2500pcs/h

|

Without dryer, drying by natural

|

53.7kw

|

|||||

|

|

|

|

Brick oven dryer or metallic dryer

|

73kw

|

||||

|

16 Chunks

|

2500-3000 pcs/h

|

Brick oven dryer or metallic dryer

|

77kw/91kw

|

|||||

|

16 Chunks

|

3500-4500 pcs/h

|

Brick oven dryer or metallic dryer

|

129kw/135kw

|

|||||

|

48 Chunks

|

5000-5500 pcs/h

|

Brick oven dryer or metallic dryer

|

150kw/160kw

|

|||||

|

60 chunks

|

6000-7000pcs/h

|

Brick oven dryer or metallic dryer

|

153kw/178kw

|

|||||