- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Weight (KG):

-

8000 kg

-

Product name:

-

E-Waste Recycled Machine

-

Application:

-

Waste Recycling Plant

-

Raw material:

-

Waste PCB

-

Final product:

-

Metal,resin powder

-

Advantage:

-

High Separator Rate 98%

-

Capacity:

-

100-1000 Kg/h

-

Function:

-

E Waste Recycling

-

Keywords:

-

Waste Circuit Board Recycling Plant

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Field Installation

Quick Details

-

Production Capacity:

-

100-1000KG/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Renewable

-

Marketing Type:

-

Hot Product 2024

-

Weight (KG):

-

8000 kg

-

Product name:

-

E-Waste Recycled Machine

-

Application:

-

Waste Recycling Plant

-

Raw material:

-

Waste PCB

-

Final product:

-

Metal,resin powder

-

Advantage:

-

High Separator Rate 98%

-

Capacity:

-

100-1000 Kg/h

-

Function:

-

E Waste Recycling

-

Keywords:

-

Waste Circuit Board Recycling Plant

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Field Installation

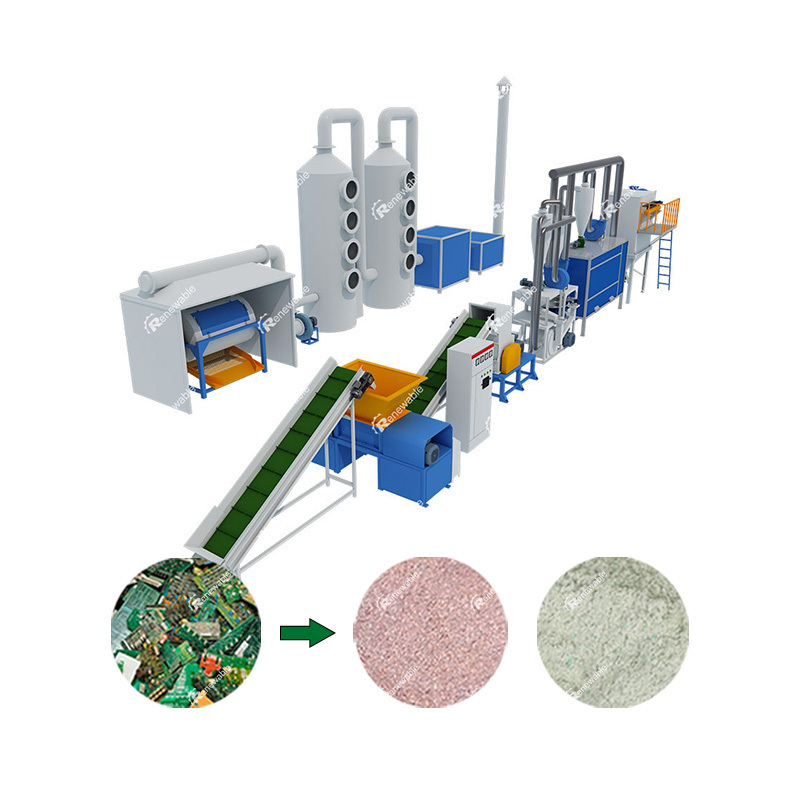

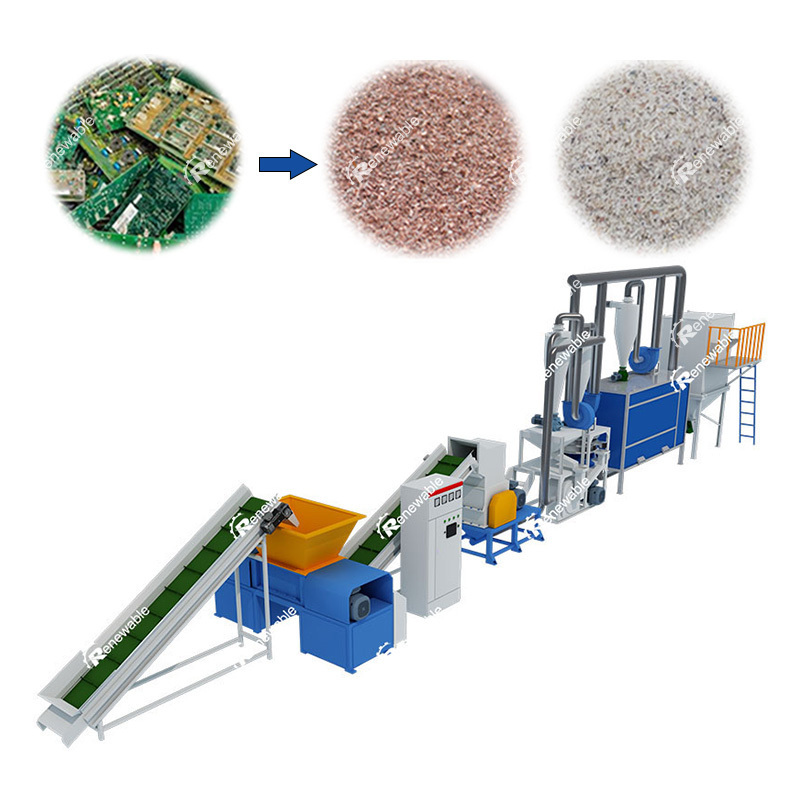

E WASTE RECYCLING PLANT

E-waste recycling machine is also called E-waste crushing and separating machine, printed circuit boards separator, electric waste process equipment, which is for recycling the circuit boards inside the TV, computer and other home appliances.

After the E-waste recycling process, it can separate the metal and nonmetal materials to get recycle use. E-waste recycling machine is apply to recycle all kinds of circuit boards, PCB boards, FPCB boards and other electric wastes.

Raw Materials

Various E waste materials such as:

Computer boards, Cell phone boards, TV boards, Copper-clad laminate

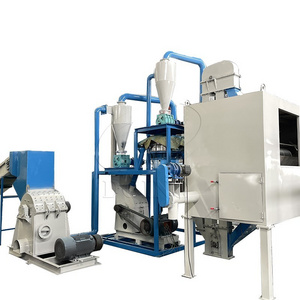

Technology Introduction

The first crusher adopts double-shaft shredding,

The second crusher adopts hammer crusher, and the third crusher adopts high-speed turbine crusher.

The material is pulverized into powder through three-stage pulverization, and then sorted by air separation equipment and electrostatic separation equipment.

The recovery rate of copper in waste circuit boards is over 98% through separation and sorting equipment.

The first crushing machine we choose the double shaft shredder,

And the second crushing machine we use the hammer crusher, and the third crushing machine we use the high speed turbine grinding machine.

The waste material will be separated by the air separator and the electrostatic separator.

This production line has the advantages of unique structure,large output and power saving.

Several machines cooperate to work after once feeding of materials.

The whole production line are controlled by PLC.

This machine has good performance in mixed metal recycling and also prevent against secondary pollution.

Final Products: Metal Powder And Resin Powder

E Waste Recycling Plant Features

1. Compact structure, reasonable layout, stable performance, low noise.

2. The recycling equipment of waste circuit board adopts two stage crushing, which can make the processing capacity reach 800kg per hour.

3. The whole production line adopts negative pressure feeding to effectively reduce dust overflow.

4. The sorting rate of airflow sorting equipment is up to 99%.

5. High voltage electrostatic separator makes sorting more fine and efficient, effectively control the loss of non-ferrous metal.

6. Equipped with magnetic separation function, iron can be separated from the material.

7. The waste circuit board recycling equipment adopts PLC to control the complete production line for uniform feeding and coordinated operation.

8. The grinding chamber adopts circulating water temperature control and noise reduction.

9. The return system makes crushing more efficient.

10. The efficiency of pulse dust removal equipment is as high as 99%, which effectively inhibits dust volatilizati

Technical Parameters

|

Model

|

Capacity

|

Power

|

Dimension

|

|

RNB-PCB 300

|

200-300 Kg/H

|

102 Kw

|

20*5*5 m

|

|

RNB-PCB 500

|

400-500 Kg/H

|

134 Kw

|

25*6*5 m

|

|

RNB-PCB 800

|

600-800 Kg/H

|

194 Kw

|

30*6*5 m

|

|

RNB-PCB 1000

|

800-1000 Kg/H

|

238 Kw

|

35*8*5 m

|

Quality Assurance

Installation And After-Sales Service

Hot Searches