- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HNOC

-

Power:

-

14KW

-

Weight:

-

6500 kg

-

Product name:

-

Tube Mill Machine

-

After-sales Service Provided:

-

Online Engineer Support

-

Pipe shape:

-

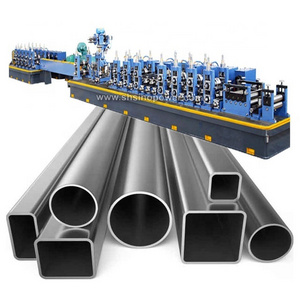

Round Square Rectangle Pipe

-

Raw material:

-

Stainless Steel

-

Keywords:

-

Pipe Make Machine

-

Usage:

-

Produce Industrial Steel Pipe

-

Welding type:

-

High Frequency Welding

-

Advantage:

-

Simple Operation

-

MOQ:

-

1 Set

Quick Details

-

Pipe Material:

-

Stainless steel

-

Production Capacity:

-

1-15m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Power:

-

14KW

-

Weight:

-

6500 kg

-

Product name:

-

Tube Mill Machine

-

After-sales Service Provided:

-

Online Engineer Support

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Raw material:

-

Stainless Steel

-

Keywords:

-

Pipe Make Machine

-

Usage:

-

Produce Industrial Steel Pipe

-

Welding type:

-

High Frequency Welding

-

Advantage:

-

Simple Operation

-

MOQ:

-

1 Set

Product Description

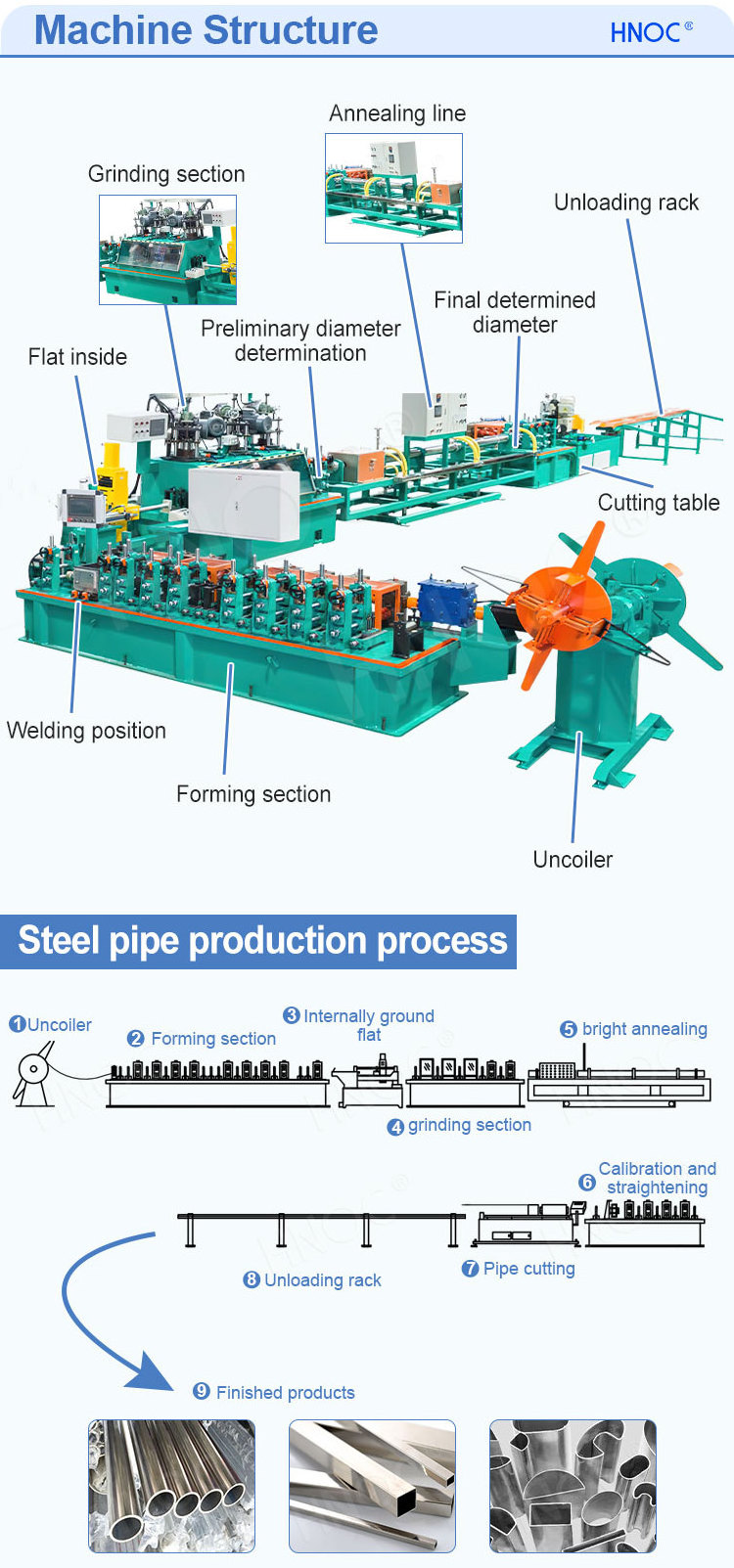

Tube mill is a mechanical equipment used for manufacturing pipes. It can process the original steel through multiple steps to form pipes of different specifications and shapes. The working principle of a pipe rolling machine is to put raw materials into the rolling machine, pass through the rolling process, heat treatment, cooling, and then precision machining to ultimately form pipes of different specifications.

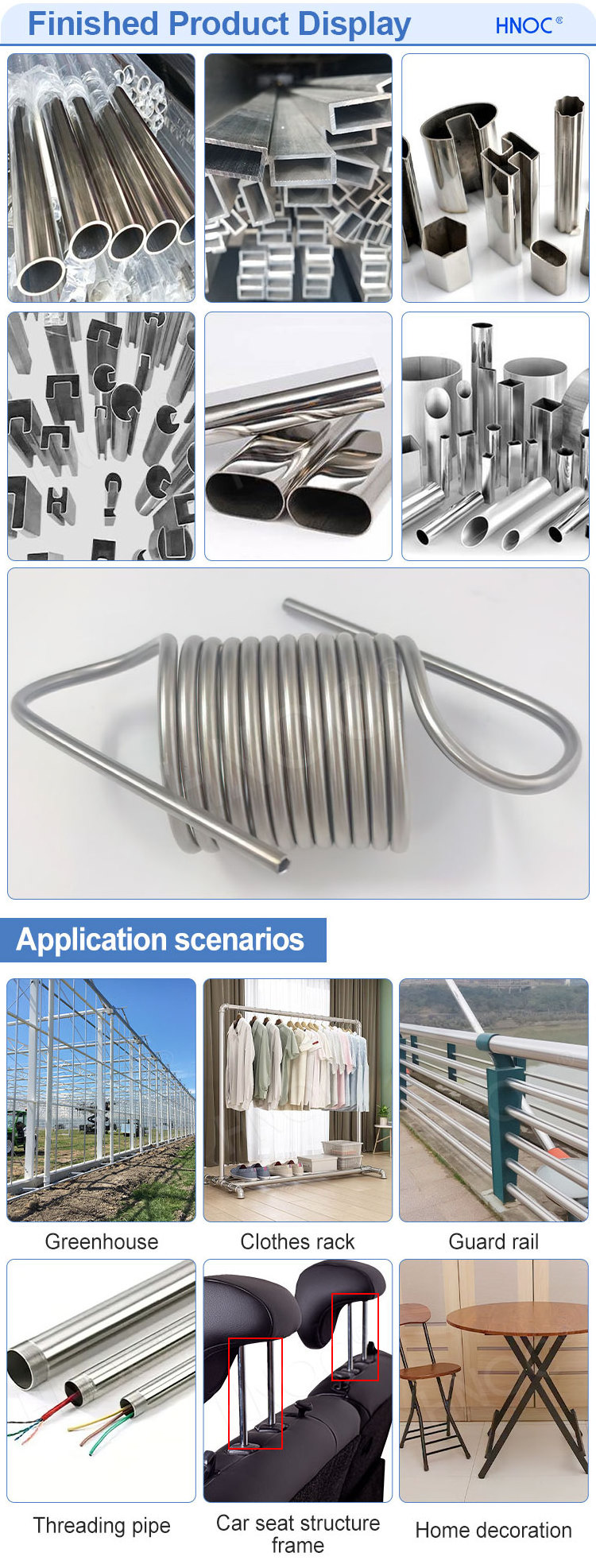

Application

Widely used in the production of food pipelines, beverage pipelines, natural gas pipelines, petrochemical pipelines, ventilation pipelines, stainless steel water pipes, metal products, household appliances, bathroom fixtures, building decoration, catering and kitchenware, edible machinery, structural piping, and other fields.

Features

1. Efficient production capacity.

Features

1. Efficient production capacity.

The automatic pipe rolling machine can complete large-scale processing tasks in a very short time, improving production efficiency and saving production costs.

2. Easy to operate, easy to learn and master.

2. Easy to operate, easy to learn and master.

The automatic pipe rolling machine has advanced automatic technology and control system, which is convenient to use, has high accuracy.

3. Stable working effect.

3. Stable working effect.

The automatic pipe rolling machine adopts high-end technology and has high-precision and high-efficiency processing capabilities. The processed products have stable quality and meet national standards.

4. Save production costs and improve competitiveness.

4. Save production costs and improve competitiveness.

The automatic pipe rolling mill effectively reduces production costs and has advantages in market competition, which can enhance the competitiveness of enterprises.

Product Parameters

|

Model

|

Horizontal shaft

|

Vertical shaft

|

Diameter

|

Thickness

|

Motor power

|

Grinding head

|

Turkish head

|

Main Engine Size(LXW)

|

|

HNOC-40

|

Φ40mm

|

Φ25mm

|

Φ9.5-50.8mm

|

0.21-3.0mm

|

7.5kw x 2

|

3 x 3kw

|

2PCS

|

7600*1150mm

|

|

HNOC-50

|

Φ50mm

|

Φ30mm

|

Φ25.4-76mm

|

0.3-3.5mm

|

11kw x 2

|

3 x 3kw

|

2PCS

|

9000*1200mm

|

|

HNOC-60

|

Φ60mm

|

Φ40mm

|

Φ50.8-114mm

|

0.5-4.0mm

|

15kw x 2

|

3 x 4kw

|

2PCS

|

11000*1500mm

|

|

HNOC-80

|

Φ80mm

|

Φ50mm

|

Φ89-159mm

|

1.0-5.0mm

|

22kw x2

|

3x 5.5kw

|

2PCS

|

12900*2100mm

|

|

HNOC-100

|

Φ100mm

|

Φ70mm

|

Φ114-273mm

|

1.0-6.0mm

|

30kw x 2

|

3x 5.5kw

|

3PCS

|

14000*2300mm

|

|

HNOC-Precision 40

|

Φ40mm

|

Φ25mm

|

Φ5-20mm

|

0.25-1.2mm

|

5.5kw

|

3x3kw

|

1PCS

|

6600*950mm

|

Product Details

Product Photograph

Hot Searches