- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAZHEN

-

Voltage:

-

fit for local use

-

Weight:

-

500 kg

-

Marketing Type:

-

vibro sifter filter / filtration equipment

-

motion:

-

circular motion

-

layer:

-

1-4

-

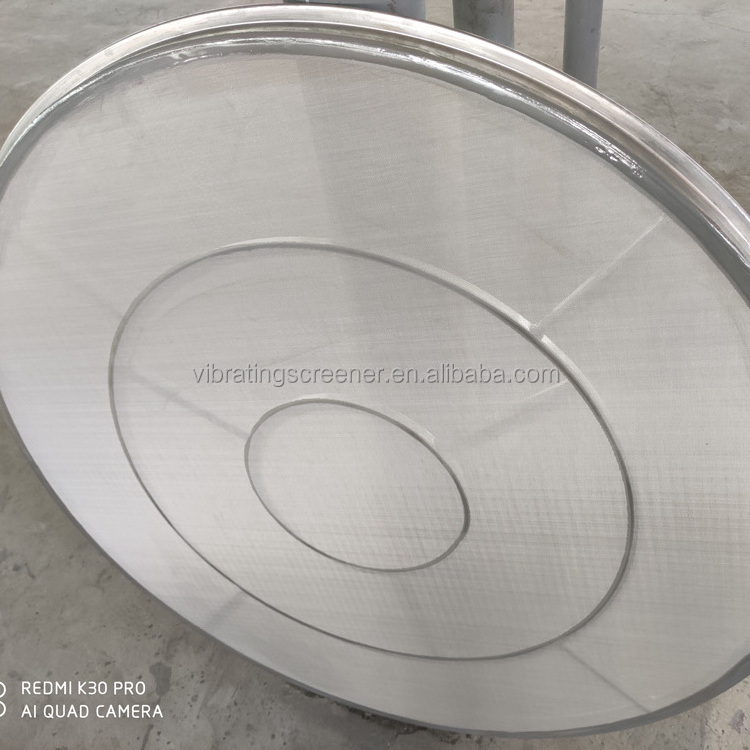

screen mesh:

-

as specified

-

construction material:

-

stainless steel

Quick Details

-

Type:

-

vibro sifter filter

-

Production Capacity:

-

based on models

-

Max. workable width:

-

N/A

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAZHEN

-

Voltage:

-

fit for local use

-

Weight:

-

500 kg

-

Marketing Type:

-

vibro sifter filter / filtration equipment

-

motion:

-

circular motion

-

layer:

-

1-4

-

screen mesh:

-

as specified

-

construction material:

-

stainless steel

round vibro sifter filter filtration equipment for

pulp and paper industry solid liquid separation

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

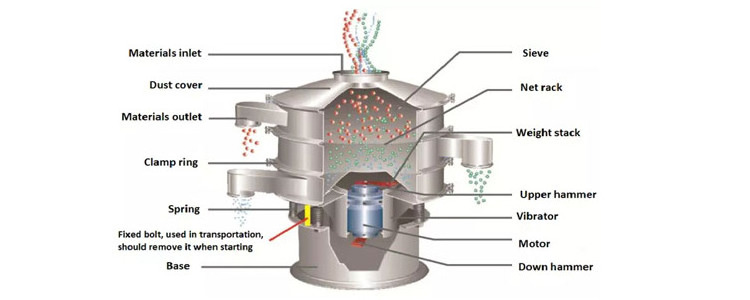

Product Description DZ vibro sifter, also known as vibro screen, vibro sieve, vibro filter, vibro separator, i s a kind of superior accurate screening / filtration equipment, which is ideal for screening powders, granules, liquids or slurries. DZ vibro sifter s filter filtration equipments are involved in ceramic, coating, pulp & paper, chemical, food & beverage, glass, abrasive, mining and other industries. Machine Structure

T echnical Parameters |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Features 1. Superior accurate separation efficiency 2. Lower noise levels 3. Ball tray or ultrasound for anti-blinding 4. Multi deck models available 5. Upper deck open or covered 6. Explosion-proof motors if required |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Q1. Are you a real factory? >> A1: Sure, we are a 30 years large factory which TUV certified.

Q2. What information to provide for getting quote? >> A2: 1. Material characteristics (including name, particle size range, bulk density, water content if slurry or liquid material, etc) 2. Capacity? 3. How many layers? 4. The mesh size for each layer? 5. local Voltage and frequency? V&HZ 6. Sea port name or address for shipment

Q3. How long for the delivery time? >> A3: 5-15 working days for general products.

Q4. How long for warranty time? >> A4: 12 months from the shipping date. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||