* Batch

Tyre

Plastic Pyrolysis Plant

* Waste

Tyre

Plastic Pyrolysis Plant

* Skid Mounted Small Pyrolysis Plant

* Semi-continuous

Tyre

Plastics

Recycling Machine

Oil

Sludge

Pyrolysis Plant

* Fully Continuous

Tyre

Plastics

Recycling Machine

Oil Sludge

Pyrolysis Plant

* Waste

Tyre

Pyrolysis Machine

Oil Sludge

To Oil Plant

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

40000 KG

-

Raw material 1:

-

Rubber/Tire

-

Raw material 2:

-

Plastic(PP/PE/ABS/PS...)

-

Raw material 3:

-

Oil sludge

-

Raw material 4:

-

Medical waste

-

Heating material:

-

Combustible gas/Diesel/Natural gas/LPG

-

Capacity:

-

12-15TPD

-

End product 1:

-

pyrolysis oil

-

End product 2:

-

Combustible gas

-

End product 3:

-

Carbon black

-

End product 4:

-

Steel wire(For tyre)

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MINGJIE

-

Equipment Capacity:

-

12-15 tons per day

-

Weight (KG):

-

40000 KG

-

Raw material 1:

-

Rubber/Tire

-

Raw material 2:

-

Plastic(PP/PE/ABS/PS...)

-

Raw material 3:

-

Oil sludge

-

Raw material 4:

-

Medical waste

-

Heating material:

-

Combustible gas/Diesel/Natural gas/LPG

-

Capacity:

-

12-15TPD

-

End product 1:

-

pyrolysis oil

-

End product 2:

-

Combustible gas

-

End product 3:

-

Carbon black

-

End product 4:

-

Steel wire(For tyre)

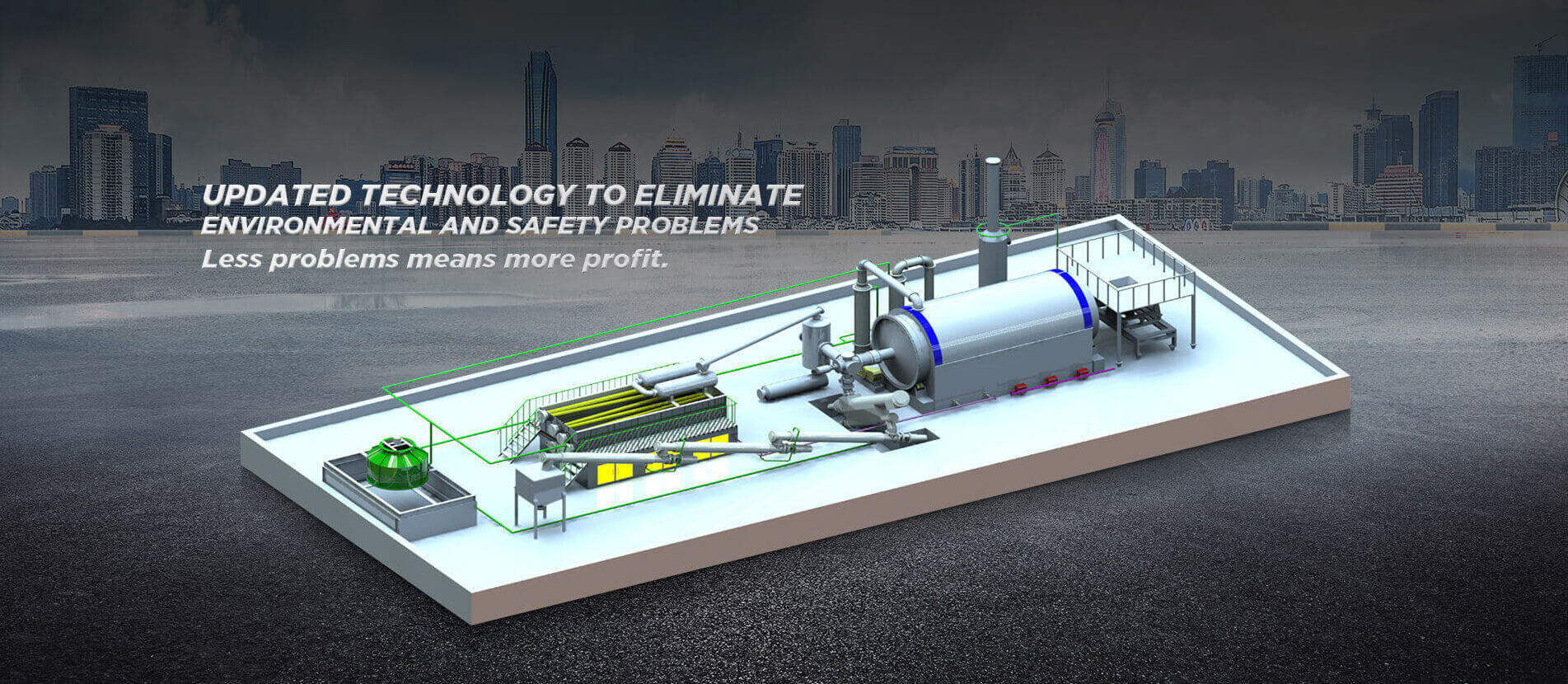

PRODUCT DESCRIPTION

Pyrolysis plant

|

Item

|

|

Content

|

|

|

|||

|

Models

|

No

|

Capacity

|

Reactor size

|

Operation

|

|||

|

|

MJ-2

|

1-2T Per Batch

|

1400*4000mm

|

Batch

|

|||

|

|

MJ-6

|

6T/D

|

2200*6000mm

|

Batch

|

|||

|

|

MJ-10

|

8-10T/D

|

2600*6600mm

|

Batch

|

|||

|

|

MJ-12

|

12T/D

|

2800*7100mm

|

Batch

|

|||

|

|

MJ-15

|

13-15T/D

|

2800*8000mm

|

Batch

|

|||

|

|

MJL-15

|

16-20T/D

|

2800*7100mm

|

Semi-continuous

|

|||

|

|

MLL-20P

|

30T/D

|

16000*26000mm

|

Fully continuous

|

|||

|

|

MLL-30T

|

35-40T/D

|

16000*26000mm

|

Fully continuous

|

|||

Raw materials

Raw materials could be waste tyre, waste plastic, oil sludge, waste cables, medical waste, MSW and so on.

Final product

PYROLYSIS OIL

Waste tyre to pyrolyssis plant can get fuel oil. Can be sold directly, widely used for cement factory, ceramic factory, boiler factory, iron factory, etc.Part of it can be used back to the pyrolysis plant for heating the reactor. Can be further refined to the non standard diesel. Can be used directly in heavy oil generator for producing electricity.

CARBON BLACK

Can be pressed to be briquettes and used as fuel for burning. Can be further reprocessed to be higher quality and used as fortifier, filler of plastic and rubber industry or as color master batch. Can be used to produce rubber pads, rubber belt, soles, etc.

STEEL WIRE

Can be sold directly to steel factory.

SYNGAS

Will be recycled to the furnace for heating the reactor.

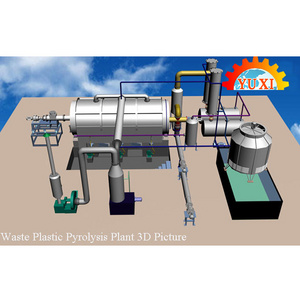

PRODUCT CONFIGURATION

Reactor

Flue condenser

Integrated condenser

Carbon black discharging Screw

Carbon black Discharging Screw with water-cooling system

Water cooling Carbon black storage tank

Heavy oil tank

Desulfurization Scrubber Tower

Cooling tower

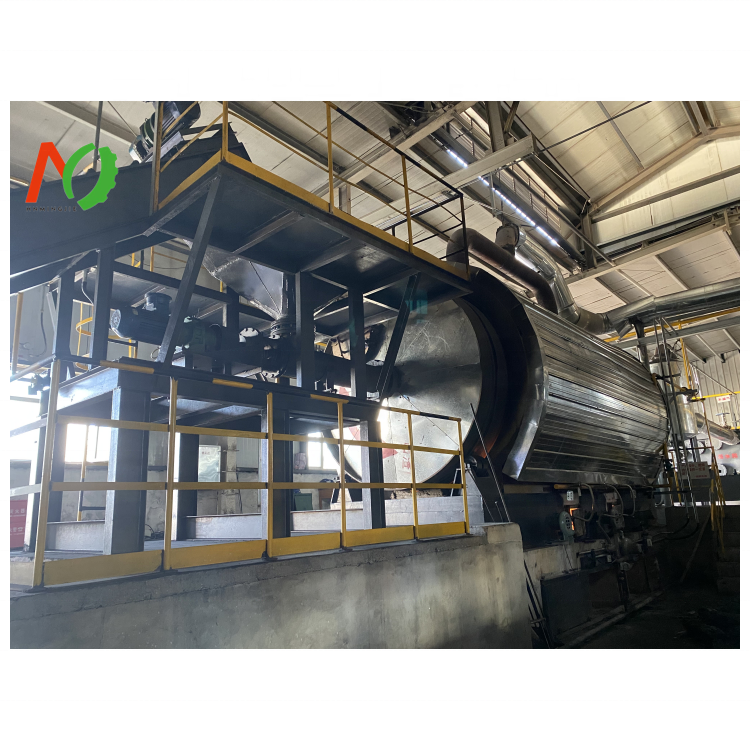

SUCCESSFUL PROJECT

Project in India

Project in

China

Project in

Malaysia

Project in

Germany

Project in

Czech Republic

Project in

Philippines

COMPANY INTRODUCTION

About MINGJIE Machinery

Henan Mingjie Environmental Equipment Co., Ltd is a high-tech environmental enterprise, covering R&D, manufacturing , sales and

exporting, We are committed to provide comprehensive solution for solid waste recycling , specializing in waste tires, waste

plastics, and oil sludge recycling pyrolysis plant, to get fuel oil and other renewable energy.

With almost 20 years manufacturing experience, a professional team for foreign trade and after-sale service, we take “ To Create Sustainable Value for Clients “ as pursuit. With abundant experience and foreseeing ability of this industry, we will continuously to provide excellent service for clients. All the products from Mingjie have been certified by CE and ISO, have been exported to India, Pakistan, Romania, Jordan , Thailand, Malaysia, and England etc, has very stable clients and good reputation in Chinese

market, Mingjie company will continuously to create value for our clients , strive to be the No.1 in the industry.

OUR ADVANTAGES

CLIENTS FROM WORLD

CERTIFICATE

FAQ

Q1:Pyrolysis yield ratio?

Tire recycling to oil pyrolysis plant.

A1:Can get about pyrolysis oil 40-45%, carbon black 30-35%, steel wire 15%, combustible gas 10%.

Q2:Whether the plastic needs to be cleaned?

A2:Plastic can be cleaved without cleaning. Cleaning plastic to increase the cost of raw materials, but the cleanliness of plastic will affect the rate of oil.

Q3:How to reduce sulfur content?

A3:Tire cracking oil sulfur content is high, because in the tire production process, there is a sulfurization process, so the tireoil sulfur content is high. Further processing by distillation can reduce the sulfur content of tire oil. In other large

refineries, there are hydrogenation processes, which can also reduce sulfur content.

A3:Tire cracking oil sulfur content is high, because in the tire production process, there is a sulfurization process, so the tireoil sulfur content is high. Further processing by distillation can reduce the sulfur content of tire oil. In other large

refineries, there are hydrogenation processes, which can also reduce sulfur content.

Hot Searches