- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1.45*1.1*0.84m

-

Weight:

-

300 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

automatic tilapia fish food floating feed fish food pellet machine

-

Screw Diameter:

-

40mm

-

Feeding Power:

-

0.4kw

-

Cutting Power:

-

0.4kw

-

Function:

-

Producing cat dog Fish Feet Pellets etc

-

Main power:

-

5.5kw

-

Color:

-

Yellow,White,blue,red or customized

-

Final Pellet Size:

-

1-12mm

-

Raw material:

-

Corn starch,wheat powder,fish powder,soybean powder etc

Quick Details

-

Max. Capacity:

-

50kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1.45*1.1*0.84m

-

Weight:

-

300 kg

-

Marketing Type:

-

New Product 2022

-

Product name:

-

automatic tilapia fish food floating feed fish food pellet machine

-

Screw Diameter:

-

40mm

-

Feeding Power:

-

0.4kw

-

Cutting Power:

-

0.4kw

-

Function:

-

Producing cat dog Fish Feet Pellets etc

-

Main power:

-

5.5kw

-

Color:

-

Yellow,White,blue,red or customized

-

Final Pellet Size:

-

1-12mm

-

Raw material:

-

Corn starch,wheat powder,fish powder,soybean powder etc

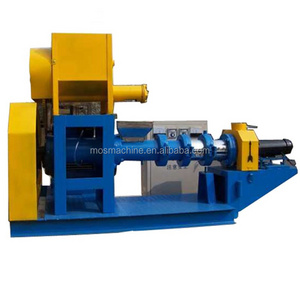

Floating Sinking Trout Fish Catfish Feed Processing machine automatic tilapia fish food floating feed fish food pellet machine

Fl oating fish feed machine is widely used for producing grains into high-grade aquatic feed pellets for fish,

catfish, shrimps, crab etc The feed pellet size can be from 0.9mm to 10mm by changing the moulds. It is suitable for making feed for small fish to big fish.

Working Principle:

The extruder is provided with a set of screw and screw sleeve, which have the function of mixing and kneading.After the raw material enters the expanded cavity, the material is squeezed, frictional, shear and other effects between the screw sleeve, and the internal pressure keeps rising, up to 4Mpa, and the temperature keeps rising, up to 140 degrees Celsius.With the sharp increase of temperature and pressure within 3-7s, the material's tissue structure changes, making starch further gelatinize, protein denaturation, crude fiber destruction, killing salmonella and other harmful bacteria.High temperature and high pressure materials come out from the outlet, the pressure is suddenly released in an instant, and part of the moisture occurs flash evaporation. After cooling, the material presents a loose and porous structure, while after expanding, the material presents a ball shape, flocculent shape or coarse debris shape.

Raw materials request:

Corn flour,wheat flour,soya flakes meal,wheat bran,bone meal,fish meal,meat meal,etc.

Fineness:60-80mesh; Moisture content:20-25%

Advantage:

|

1 |

With different moulds, the machine can produce different diameter food, from 0.9mm to 10 mm. The food can meet different stage fish. The food can be floating 24hours |

|

2 |

It can produce different shapes feed for fish, dog, cat etc. |

|

3 |

Through the pretreatment of the feed, it can reduce loss of nutrition and advance the protein ratio.So the feed will be digested easily by animals. |

Details Specification:

|

Model |

QS -40 |

QS -50 |

QS -60 |

QS -70 |

QS -80 |

QS -90 |

|

Screw Diameter |

Φ 40mm |

Φ 50mm |

φ60mm |

φ70mm |

φ80mm |

φ90mm |

|

Capacity |

40-50kg/h |

80-100kg/h |

120-150kg/h |

180-200kg/h |

260-300kg/h |

320-350kg/h |

|

Main Power |

5.5kw |

1 1 kw |

15kw |

18.5kw |

22kw |

37kw |

|

Feeding Powe r |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

1.1kw |

|

Cutting Power |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

1.1kw |

1.5kw |

|

Weight |

300kg |

350kg |

400kg |

450kg |

700kg |

900kg |

|

Overall size |

1.45*1.1*0.84m |

1.47*1.12*0.84 |

1.65*1.26*0.9 |

1.79*1.47*0.94 |

2.05*1.5*0.95 |

2.35*1.64*1.0 |

|

Voltage |

380V 50HZ 3phase or customized |

|||||

|

Final pellets |

Dia.1-12mm (standard 3pcs, other can add) |

|||||

|

Usages |

Aquatic feed pellets: fish, shrimp, frog etc.

|

|||||

Packing: Nude or plywood case or customized.

Delivery Date: 10-20 days after confirm the down payment.

Shipping Method: By sea

Shipping Port: Qingdao, China or any port in China

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life