- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zahdnent

-

Model Number:

-

ZDM-5T

-

Model:

-

ZDM-5T

-

Axis:

-

5

-

Milling mode:

-

Wet and Dry

-

Product type:

-

Crown/Coping,Bridge,Inlay/Onlay,Veneer etc

-

Max spindle speed:

-

60000RPM/min

-

Spindle cooling:

-

Water cooling

-

Spindle power:

-

2700W

-

Number of burs(Tools) housed:

-

12

-

Tool change:

-

Automatic

-

Potitioning accuracy:

-

0.002mm

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Place of Origin:

-

zhejiang

-

Brand Name:

-

Zahdnent

-

Model Number:

-

ZDM-5T

-

Model:

-

ZDM-5T

-

Axis:

-

5

-

Milling mode:

-

Wet and Dry

-

Product type:

-

Crown/Coping,Bridge,Inlay/Onlay,Veneer etc

-

Max spindle speed:

-

60000RPM/min

-

Spindle cooling:

-

Water cooling

-

Spindle power:

-

2700W

-

Number of burs(Tools) housed:

-

12

-

Tool change:

-

Automatic

-

Potitioning accuracy:

-

0.002mm

Overview:

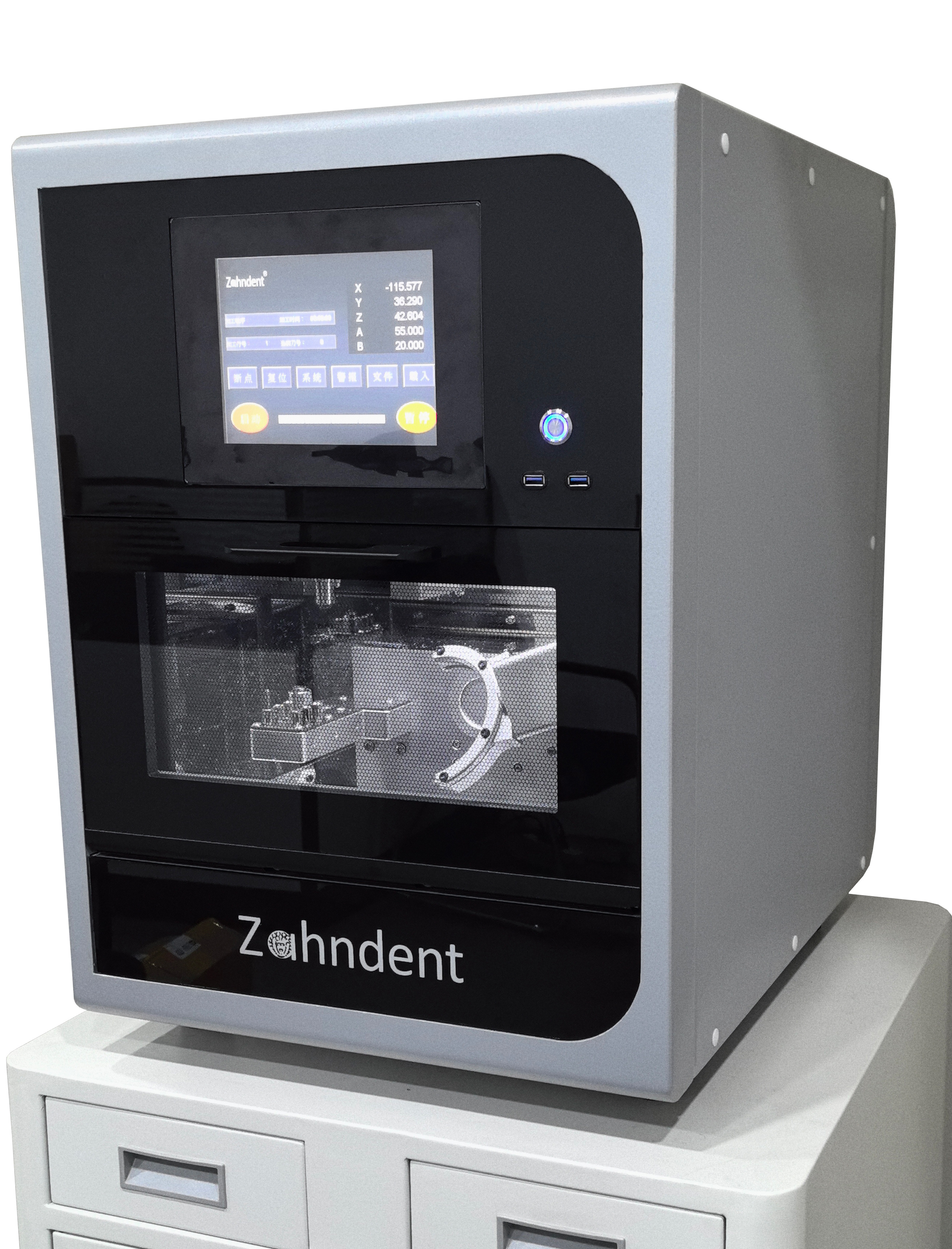

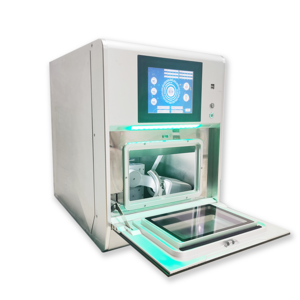

SDM5T is a 5-Axis dry-milling and wet-milling machine for dental CAD/CAM system with wide range of materials, featuring high accuracy, durable stability and excellent compatibility. It is an ideal choice for high-precision restorations including bridges, frames, splint, abutment, base and complicated operations like zirconia perforation. Equipped with premium spindle, imported core parts, smart CAM nesting system and intelligent touch screen, SDM5T offffers better disc handling, wider material capabilities,automatic tool change to deliver a higher efficiency

Key features:

1.Open controller system

This system supports international ISO standard G code, compatible with popular CAM software, such as HyperDent, SUM3D MillBox,GO2dental, WorkNC dental ,Delcam Dental etc.

2.Intelligent processing

Excellent and simple man-machine interface, touch screen control, simple operation, unique CAD/CAM processing strategy, no need for professional CNC programmers, one-button operation, stable operation.

3.High Accuracy

The body structure adopts the industrial standard cast iron and cast aluminum structure, high rigidity, no deformation, stable precision, long service life. The mechanical transmission part adopts Taiwan/Germany C3 grade high precision ball screw and Pgrade linear guide rail.

4.Double side support at A and B axis

This system supports international ISO standard G code, compatible with popular CAM software, such as HyperDent, SUM3D MillBox,GO2dental, WorkNC dental ,Delcam Dental etc.

2.Intelligent processing

Excellent and simple man-machine interface, touch screen control, simple operation, unique CAD/CAM processing strategy, no need for professional CNC programmers, one-button operation, stable operation.

3.High Accuracy

The body structure adopts the industrial standard cast iron and cast aluminum structure, high rigidity, no deformation, stable precision, long service life. The mechanical transmission part adopts Taiwan/Germany C3 grade high precision ball screw and Pgrade linear guide rail.

4.Double side support at A and B axis

Strong rigidity, the tool does not rebound during high intensity cutting.

5.High Efficiency

It adopts high power frequency conversion and high speed tool changing spindle with large torque, high precision, and it can process various materials with high effiffifficiency.

6.OEM customize

This machine is completely developed and designed by us, so we can provide customers with OEM service.

5.High Efficiency

It adopts high power frequency conversion and high speed tool changing spindle with large torque, high precision, and it can process various materials with high effiffifficiency.

6.OEM customize

This machine is completely developed and designed by us, so we can provide customers with OEM service.

|

Model

|

SDM5T

|

|

Axis

|

5

|

|

Milling mode

|

Dry/Wet

|

|

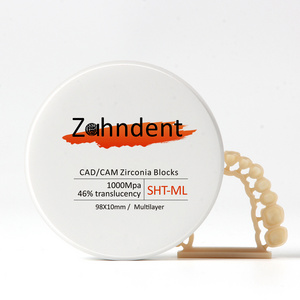

Millable material

|

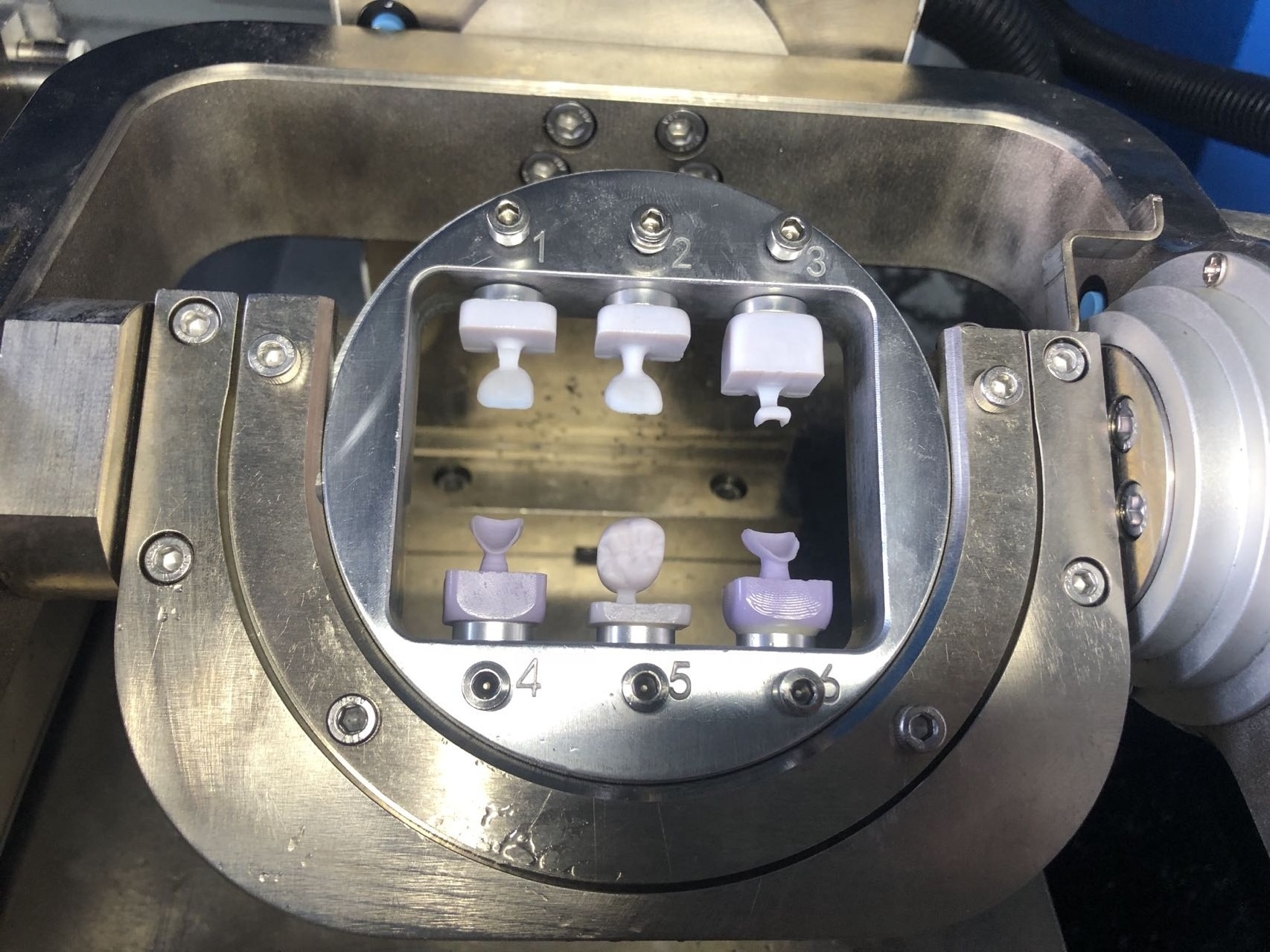

Coping/Crown, Inlay/Onlay, Bridge, Veneer, Premilled abutment, Customized abutment.Partial framework, Surgical guide, Model, Full

denture, abutment bridge, implant bar |

|

Product type

|

Crown/coping, Bridge, Inlay/onlay, Veneer, Premilledabutment

|

|

Average milling time(Dental crown)

|

Zirconia 6-10 min, PMMA 12 min, Wax 3-6 min, Titanium 22-28min

|

|

Max spindle speed

|

3000-60000 RPM/min

|

|

Loadable workpiece shape

|

External Diameter 98 mm, Max. height 25 mm, Min. height 10 mm

|

|

Spindle cooling

|

Water cooling

|

|

Spindle power

|

1500W

|

|

Number of burs(Tools) housed

|

14 pcs

|

|

External dimension

|

890*700*1590mm

|

|

Packing dimension

|

1050*850*1850mm

|

|

N.W/G.W

|

115 kg/137 kg

|

|

Language

|

English/Chinese

|

More Models

Hot Searches