- Product Details

- {{item.text}}

Quick Details

-

Tensile Strength:

-

10Mpa

-

Wall Thickness:

-

0.12mm

-

Color:

-

Black, Clear or customized

-

Shrink ratio:

-

2:1

-

Flammability:

-

VW 1

-

Adhesive:

-

without adhesive

-

Sample:

-

Sample Avaliable

-

Packing:

-

100m/roll

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Flyron

-

Model Number:

-

KYNAR

-

Tensile Strength:

-

10Mpa

-

Wall Thickness:

-

0.12mm

-

Color:

-

Black, Clear or customized

-

Shrink ratio:

-

2:1

-

Flammability:

-

VW 1

-

Adhesive:

-

without adhesive

-

Sample:

-

Sample Avaliable

-

Packing:

-

100m/roll

Kynar PVDF 150-175 heat shrink tubing

Products Description

It is made of radiation cross-linked special fluoropolymer PVDF. It has excellent chemical resistance and solvent resistance. It is a strong, semi-hard, thin-walled heat shrinkable tube, especially suitable for high temperature resistance and wear resistance. Environments that require high mechanical performance, such as insulation protection of cable connections and parts in aerospace, radar, locomotives, etc. It is used for the insulation protection and stress relief of the connection and the identification of the covered components. It can also be used for the protection of cable signs.

|

Characteristics

:

|

|

|

|

|

||||

|

* Shrink ratio 2:1

|

|

|

|

|

||||

|

* Semi-rigid, thin-walled insulation

|

|

|

|

|

||||

|

* Excellent flame retardancy

|

|

|

|

|

||||

|

* High temperature resistance 185℃

|

|

|

|

|

||||

|

* Good toughness, excellent wear resistance and chemical corrosion resistance

|

|

|

|

|

||||

|

Operating Temperature Range:

|

|

|

|

|

||||

|

* Continuous use temperature: -55℃~185℃

|

|

|

|

|

||||

|

* Minimum initial shrinkage temperature: 155℃

|

|

|

|

|

||||

|

* Minimum complete shrinkage temperature: 175℃

|

|

|

|

|

||||

|

Technical Performance

|

|

|

|

|||

|

Property

|

Requirement Date

|

Test method/condition

|

Typical Value

|

|||

|

Longitudinal Shrinkage Rate

|

≤10%

|

ASTM D 2671

|

≤5%

|

|||

|

Tensile strength

|

34.5 MPa min.

|

ASTM D 638

|

≥45MPa

|

|||

|

Ultimate elongation

|

150% min.

|

ASTM D 638

|

≥300%

|

|||

|

Ultimate elongation after aging

|

50% min.

|

250℃×168h

|

≥200%

|

|||

|

Volume Resistivity

|

≥10 13 Ω.cm

|

ASTM D 876

|

≥10 13 Ω.cm

|

|||

|

Cold bending flexible

|

No tracks

|

-55℃×4h

|

No tracks

|

|||

|

Heat shock

|

No tracks

|

300℃×4h

|

No tracks

|

|||

|

corrosive characteristics

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|||

|

Flammability

|

VW-1

|

UL 224

|

VW-1

|

|||

Product Paramenters

|

Dimensions (2:1)

|

|

|

|

|

||||

|

Size(mm)

|

As Supplied D (mm)

|

After full recovered (mm)

|

|

Standard package

|

||||

|

|

|

Inner diameter D

|

Wall thickness W

|

(M/Roll)

|

||||

|

Φ0.8

|

≥0.8

|

≤0.4

|

0.25±0.05

|

200

|

||||

|

Φ1.0

|

≥1.0

|

≤0.5

|

0.25±0.05

|

200

|

||||

|

Φ1.2

|

≥1.2

|

≤0.6

|

0.25±0.05

|

200

|

||||

|

Φ1.6

|

≥1.6

|

≤0.8

|

0.25±0.05

|

200

|

||||

|

Φ2.4

|

≥2.4

|

≤1.2

|

0.25±0.05

|

200

|

||||

|

Φ3.2

|

≥3.2

|

≤1.6

|

0.25±0.05

|

200

|

||||

|

Φ4.8

|

≥4.8

|

≤2.4

|

0.25±0.05

|

100

|

||||

|

Φ6.4

|

≥6.4

|

≤3.2

|

0.30±0.08

|

100

|

||||

|

Φ9.5

|

≥9.5

|

≤4.8

|

0.30±0.08

|

100

|

||||

|

Φ12.7

|

≥12.7

|

≤6.4

|

0.30±0.08

|

100

|

||||

|

Φ15.0

|

≥15.0

|

≤7.5

|

0.40±0.08

|

100

|

||||

|

Φ19.1

|

≥19.1

|

≤9.5

|

0.43±0.08

|

50

|

||||

|

Φ25.4

|

≥25.4

|

≤12.7

|

0.48±0.08

|

50

|

||||

|

Φ38.1

|

≥38.1

|

≤19.1

|

0.51±0.08

|

50

|

||||

|

Φ50.8

|

≥50.8

|

≤25.4

|

0.58±0.08

|

50

|

||||

|

* Other specifications and sizes can be customized

|

|

|

|

|

||||

|

* Standard color: transparent, black

|

|

|

|

|

||||

|

* Other colors can be customized

|

|

|

|

|

||||

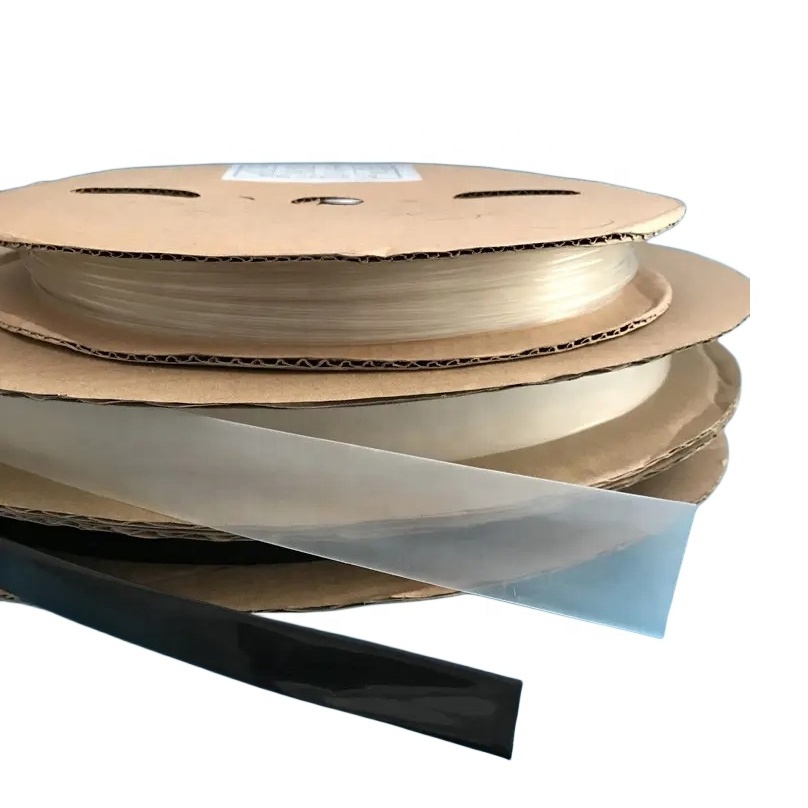

Details Images

Product packaging

Hot Searches