- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

NA

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinghe

-

Model Number:

-

CR EMSG-231

-

Type:

-

one component

-

Product name:

-

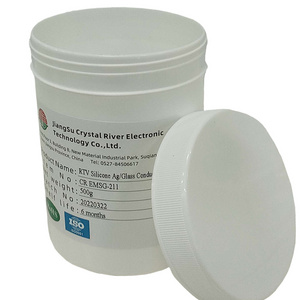

RTV Silicone Ag/Ni Conductive Glue

-

Material:

-

Silicone

-

Application:

-

Communication base

-

Curing method:

-

Moisture curing

-

Shielding effectiveness:

-

>100 dB

-

Working temperature:

-

- 50~125℃

-

Density@ Cured:

-

3.8±0.1 g/cm³

-

Shore A hardness:

-

60

-

Storage condition:

-

-20℃

-

Shelf life:

-

6 months

Quick Details

-

CAS No.:

-

mixture

-

Other Names:

-

RTV Silicone conductive Adhesive

-

MF:

-

mixture

-

EINECS No.:

-

NA

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinghe

-

Model Number:

-

CR EMSG-231

-

Type:

-

one component

-

Product name:

-

RTV Silicone Ag/Ni Conductive Glue

-

Material:

-

Silicone

-

Application:

-

Communication base

-

Curing method:

-

Moisture curing

-

Shielding effectiveness:

-

>100 dB

-

Working temperature:

-

- 50~125℃

-

Density@ Cured:

-

3.8±0.1 g/cm³

-

Shore A hardness:

-

60

-

Storage condition:

-

-20℃

-

Shelf life:

-

6 months

Product Description

CR EMSG-231

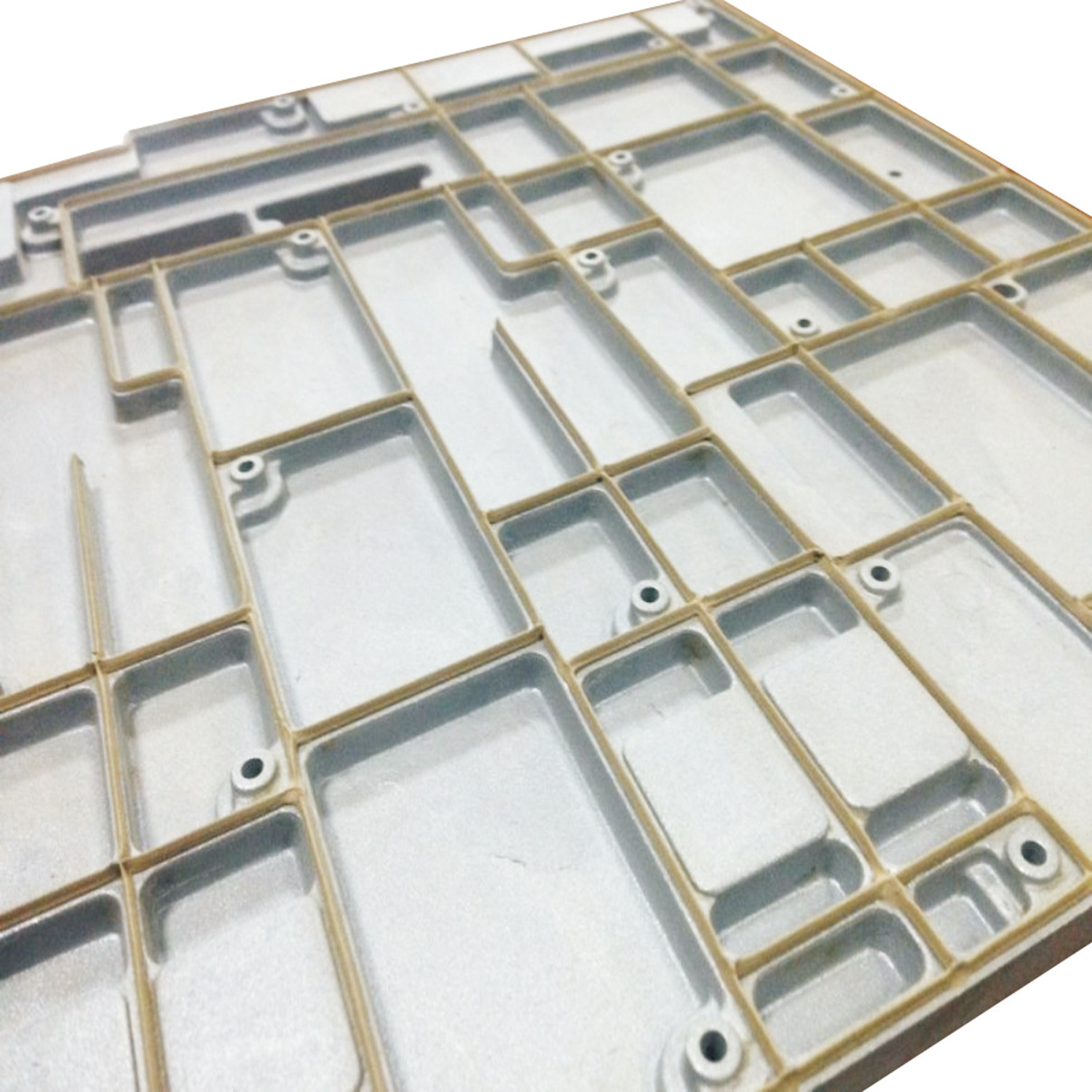

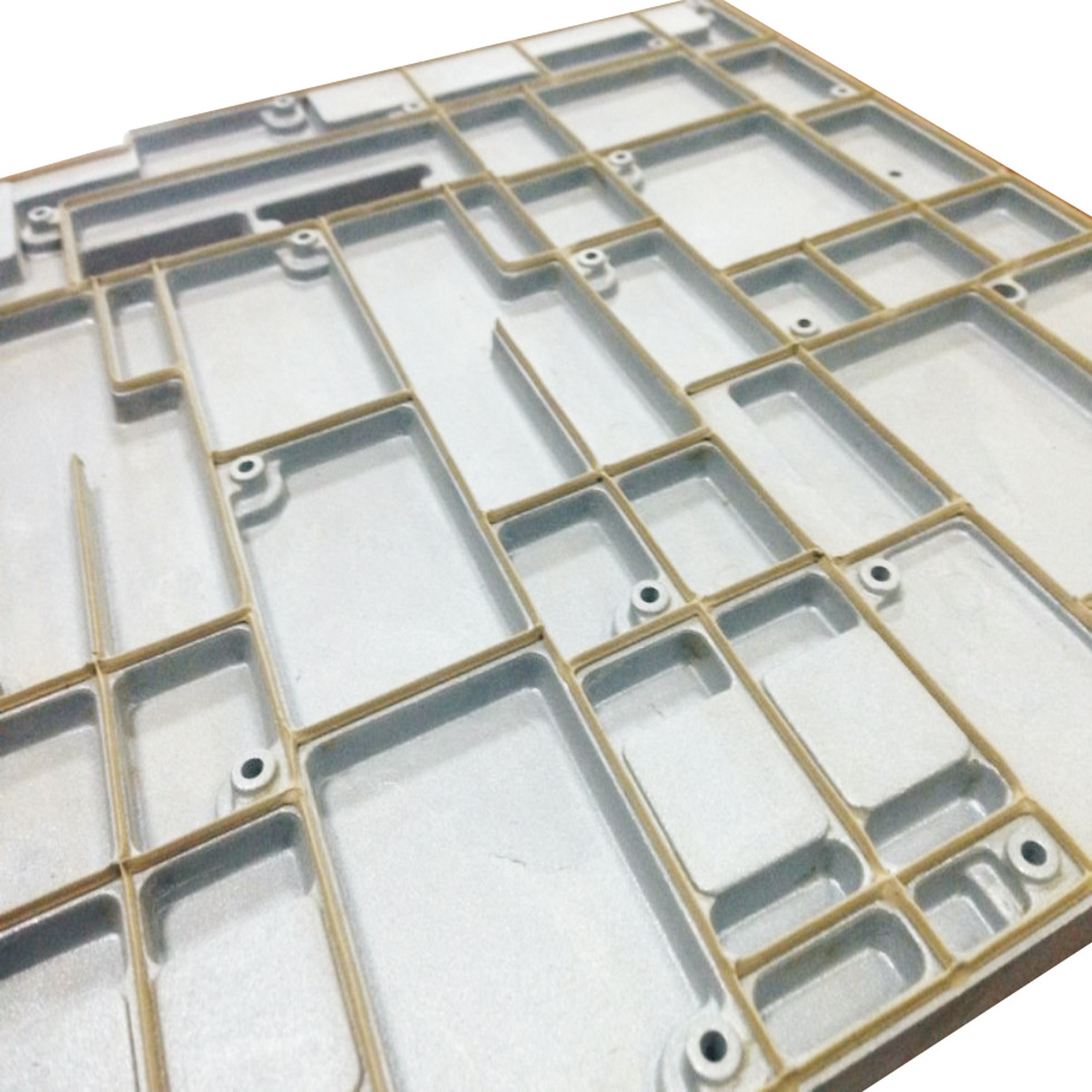

is a one-part room temperature moisture curing silicone conductive glue filled with silver-coated nickel powder. It can be molded using FIP dispensing process. With low viscosity, it can guarantee short production cycle on any type of dispenser. Tack dry time and full cure time decrease with increasing temperature and humidity. It has excellent shielding effectiveness and excellent bond strength. In low compression set, it has good heat resistance and moisture resistance.

Properties

●Can be dispensed on metal or plastic substrates

●Excellent electromagnetic shielding performance

●Good thixotropy and adhesion

Applications

●

Military electronic equipment

●Communication base station

●Automotive Electronics

Specification

|

TYPICAL VALUES

|

TEST METHOD

|

UNITS

|

CR EMSG-231

|

|

Compposition

|

/

|

/

|

One-part

|

|

Elastomer type

|

/

|

/

|

Silicone

|

|

Filler type

|

/

|

/

|

Ag/Ni

|

|

Curing way

|

/

|

/

|

Moisture curing

|

|

Curing conditions

|

Jinghe lab

|

℃/RH

|

15~40/50

|

|

Time before handling@ 23℃/50RH

|

Jinghe lab

|

hour

|

1

|

|

Full cure@23℃/50RH/△Sample dimension::W=1.3mm&T=1.6mm

|

Jinghe lab

|

hours

|

24

|

|

Volume resisvity@Sample dimension:Φ14.3mm&T=2.1

mm/Compression rate:15% |

MIL-DTL-83528C

para4.5.10

|

Ohm-cm

|

≤0.005

|

|

Shielding effectiveness@0.2~10GHz

|

Cavity to cavity testmethod

|

dB

|

>100

|

|

Density@ Uncured

|

ASTM D1475

|

g/cm

3

|

3.6±0.1

|

|

Density@ Cured

|

ASTM D792

|

g/cm

3

|

3.8±0.1

|

|

Hardness@ Sample dimension: ϕ45mm&T=6.3mm

|

ASTM D2240

|

Shore A

|

60±5

|

|

Tensile strength@ Die C

|

ASTM D412

|

MPa

|

≥1.3

|

|

Elongation at break@Die C

|

ASTM D412

|

%

|

>110

|

|

Compression set@100℃&72hours/Sample dimension:Φ13.0mm&T=6.0mm/Compression rate:25%

|

ASTM D395

Method B

|

%

|

<65

|

|

Adhesion to surface@Aluminum alloy substrate/△Gasket dimension: W=1.3mm&T=1.6mm

|

Jinghe

|

N/cm

|

>15

|

|

Operating temp.range

|

/

|

℃

|

-50~125

|

|

Flame retardant grade

|

UL94

|

/

|

V0

|

|

Storage condition,±2

|

/

|

℃

|

-20

|

|

Shelf life@ -20±2℃

|

/

|

months

|

6

|

Hot Searches