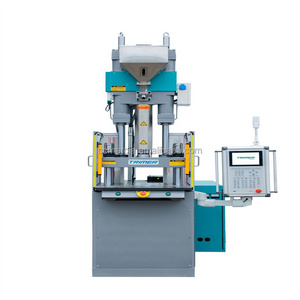

- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

44 g

-

Screw diameter (mm):

-

25 mm

-

Weight (KG):

-

750

-

Open Stroke(mm):

-

180 mm

-

Model Number:

-

YT-150A

-

Brand Name:

-

KEBIDA

-

Power (kW):

-

6 kW

-

Clamping Force (kN):

-

150 kN

-

Certification:

-

CE

-

Application:

-

Inserting Plastic Products

-

Voltage:

-

380V/220/415V

-

Space Between Tie-Bare:

-

320*180mm

Quick Details

-

Ejector Stroke(mm):

-

55 mm

-

Ejector Force(kN):

-

170 kN

-

Theoretical Shot Volume(cm³):

-

49 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

44 g

-

Screw diameter (mm):

-

25 mm

-

Weight (KG):

-

750

-

Open Stroke(mm):

-

180 mm

-

Model Number:

-

YT-150A

-

Brand Name:

-

KEBIDA

-

Power (kW):

-

6 kW

-

Clamping Force (kN):

-

150 kN

-

Certification:

-

CE

-

Application:

-

Inserting Plastic Products

-

Voltage:

-

380V/220/415V

-

Space Between Tie-Bare:

-

320*180mm

Product Description

Specification

|

Injection weight

|

1To 600g

|

|

Clamping Force

|

15 To 250Ton

|

|

Machinery Type

|

Standard And Single Plate And Double Plate And Rotray Vertical Machine

|

|

Machine Certificate

|

CE

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profie

18 Years Of Injection Molding Machine Manufacturing Experience.

Quality Guarantee.

Energy Saving Injection Machine .

ISO CE Certificate.

Standard And Single Plate And Double Plate And Rotray Vertical Machine

FAQ

Q:How to choose injection molding machine?

A:The injection weight should be about 1.2× product's weight; The tie bar space should be bigger than the mold dimension; Contact with us for more information.

Q:How to pay?

A:40% deposit T/T in advance, the balance 60% payment by T/T before delivery (we accept payment by T/T, L/C etc.)

Q:Is that possible for your company to send engineer to install machine for commissioning, even train our workers?

A:Yes, we can send our engineer to your factory for installing, commissioning, training. We have some engineers flying among different countries for after sale service and technical support. As per experience, if everything OK usually 5-15 days is enough.Therefore, before shipment, we need you to prepare invitation letter for visa. However, please be noted that all cost happened for visa, travel, hotel should be paid in advance by customers. In addition, we cannot guarantee each visa is successful.

Q:If we buy your machines, is there any warranty?

A:Yes, definitely. Totally 24-months warranty after shipment for mechanical parts, hydraulic parts, electric components (The screw just has 6-months). We are responsible for broken parts within 24-months. We will supply those parts in freeway but the possible transportation cost should be paid by clients.

Q:What is different with A,B,C screw, What is the price different?

A:The screw model is designed for different material and requirements, the screw diameter Changes from small, middle and big. There is no price difference in the price for choosing A/B/C screw types.

Q:How to choose the screw ?

A:For PC,Pa(Nylon)and other high viscosity material ,it's better to choose A screw .

For PP,PE,PS materials, better to choose B Screw .

For Recycled material , better to choose C screw .

Q:What's the delivery preriod after place the order?

A:Normally the delivery date will be in one month after receiving the down payment .

A:The injection weight should be about 1.2× product's weight; The tie bar space should be bigger than the mold dimension; Contact with us for more information.

Q:How to pay?

A:40% deposit T/T in advance, the balance 60% payment by T/T before delivery (we accept payment by T/T, L/C etc.)

Q:Is that possible for your company to send engineer to install machine for commissioning, even train our workers?

A:Yes, we can send our engineer to your factory for installing, commissioning, training. We have some engineers flying among different countries for after sale service and technical support. As per experience, if everything OK usually 5-15 days is enough.Therefore, before shipment, we need you to prepare invitation letter for visa. However, please be noted that all cost happened for visa, travel, hotel should be paid in advance by customers. In addition, we cannot guarantee each visa is successful.

Q:If we buy your machines, is there any warranty?

A:Yes, definitely. Totally 24-months warranty after shipment for mechanical parts, hydraulic parts, electric components (The screw just has 6-months). We are responsible for broken parts within 24-months. We will supply those parts in freeway but the possible transportation cost should be paid by clients.

Q:What is different with A,B,C screw, What is the price different?

A:The screw model is designed for different material and requirements, the screw diameter Changes from small, middle and big. There is no price difference in the price for choosing A/B/C screw types.

Q:How to choose the screw ?

A:For PC,Pa(Nylon)and other high viscosity material ,it's better to choose A screw .

For PP,PE,PS materials, better to choose B Screw .

For Recycled material , better to choose C screw .

Q:What's the delivery preriod after place the order?

A:Normally the delivery date will be in one month after receiving the down payment .

Hot Searches