- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TL-20

-

Voltage:

-

220V/DC24V

-

Power:

-

26KW

-

Dimension(L*W*H):

-

1300*900*1600

-

Weight:

-

380 kg

-

Application:

-

Waste Oil Refinery Equipment

-

Advantages:

-

Environmentally Friendly

-

Usage:

-

Used Oil Regeneration Device

-

Heating method:

-

Indirect Heating

-

Working temperature:

-

30~80

-

Feature:

-

Effecient

Quick Details

-

Marketing Type:

-

New Product 2021

-

Flow:

-

20L/min

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

TL-20

-

Voltage:

-

220V/DC24V

-

Power:

-

26KW

-

Dimension(L*W*H):

-

1300*900*1600

-

Weight:

-

380 kg

-

Application:

-

Waste Oil Refinery Equipment

-

Advantages:

-

Environmentally Friendly

-

Usage:

-

Used Oil Regeneration Device

-

Heating method:

-

Indirect Heating

-

Working temperature:

-

30~80

-

Feature:

-

Effecient

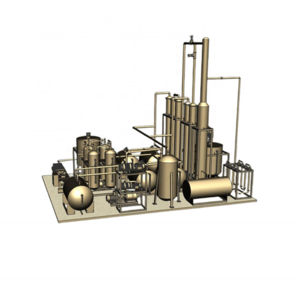

Technical Parameter

Technical Parameter

| Parameter | Unit | TL-10 | TL-20 | TL-30 | TL-50 | TL-80 | TL-100 | TL-150 | TL-200 | TL-300 | TL-500 | |

| Flowrate | L/min | 10 | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | 500 | |

| Vacuum Range | MPa | -0.06~-0.095 | ||||||||||

| Working Pressure | MPa | ≤0.5 | ||||||||||

| Working Temperature | ℃ | ≤3080 | ||||||||||

| Heating Power | KW | 18 | 24 | 30 | 36 | 48 | 60 | 81 | 90 | 120 | 150 | |

| Total power | KW | 20 | 26 | 33 | 39 | 52 | 64 | 87 | 97 | 132 | 166 | |

| Inlet(outlet)Diameter | mm | Φ25 | Φ32 | Φ32 | Φ32 | Φ42 | Φ42 | Φ48 | Φ60 | Φ76 | Φ108 | |

| Net Weight | kg | 350 | 380 | 430 | 550 | 600 | 800 | 850 | 1000 | 1180 | 2200 | |

| Overall Dimensions | L | mm | 1300 | 1300 | 1350 | 1400 | 1450 | 1500 | 1550 | 1700 | 1850 | 2200 |

| W | mm | 850 | 900 | 950 | 1000 | 1000 | 1100 | 1150 | 1400 | 1450 | 1800 | |

| H | mm | 1500 | 1600 | 1700 | 1700 | 1700 | 1750 | 1800 | 1850 | 1900 | 2100 | |

Performance Index

| Item | Index after processing |

| Content of granule | ≤6G(NAS 1638) |

| Content of water | ≤80ppm |

| Demulsifying value | ≤15min (GB/T7605) |

| Flash point | >172℃(GB/T 3536) |

| Rust Test in Liquid Phase | GB/T 3536 |

| Mechanical Impurities | (GB/T 511)No |

Application

Widely used in power, metallurgy, chemical industry and other industries for steam turbine, water turbine, gas turbine and turbine generator set turbine oil online purification treatment. It can demulsify and dehydrate turbine oil and low viscosity lubricating oil with severe water intake, turbidity and emulsification, remove the mechanical impurities such as water, soap, gum, acid, pigment and metal particles in the oil, and make the emulsified oil transparent and clear. It is also used for purifying steam turbine oil used in other machinery and power equipment or hydraulic transmission oil and anti-wear hydraulic oil based on steam turbine oil.

Features

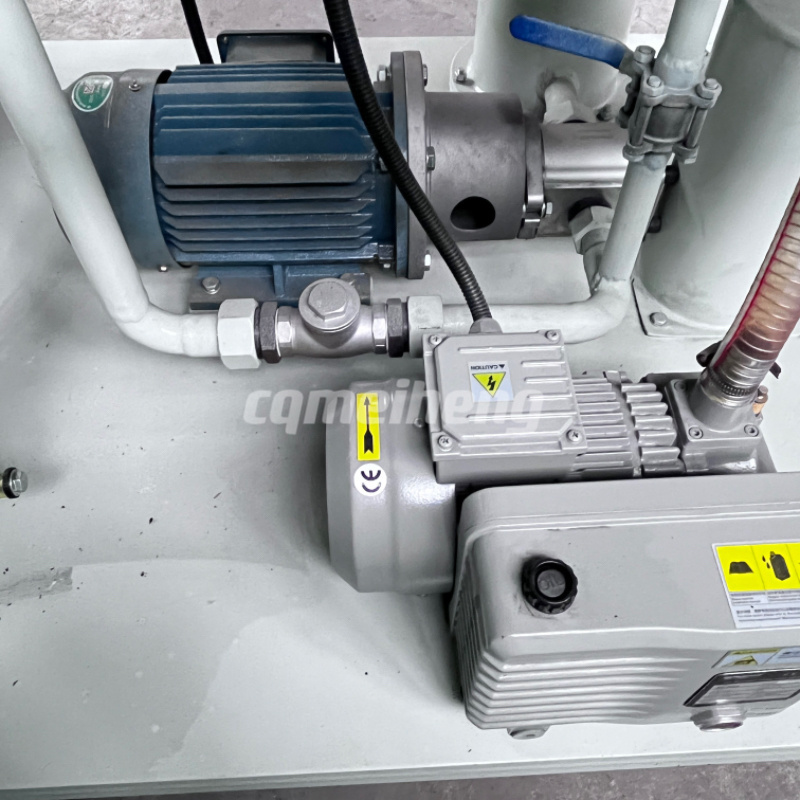

1. The polymer magnetic material imported from Germany is used as filter equipment, multi-level precision filtration, step by step encryption, to ensure high filtration accuracy, so that the filtered impurities contain particle size ≤5μm.

2. The combination of aggregation and separation technology and three-dimensional flash technology can easily treat severely emulsified oil without the use of deemulsifier. The use of efficient degassing elements and UK technology can quickly separate the water and gas in the oil, and the degassing and dehydration efficiency is high.

3. The equipment is equipped with advanced liquid level control instrument, which can automatically adjust the oil balance in and out, truly achieve man-machine separation, and make the operation more convenient and reliable. And has a trinity interlock automatic safety protection function to avoid the adverse effects of misoperation.

4. The equipment is equipped with automatic pressure control protection device. When the working pressure exceeds the set rated pressure, the power supply will be automatically cut off and the equipment will automatically stop. The filter is equipped with a sound and light pressure difference automatic alarm device. When the filter element is blocked so that the pressure reaches a certain value, the audible and light alarm signal will be automatically issued to protect the normal operation of the equipment.

5. The use of domestic well-known electrical appliances as the main control components, so as to fully ensure the high performance of the equipment continuous operation without fault.

6. Using special precision oil pump, stable operation in vacuum state, strong suction energy, low noise, to meet the requirements of environmental protection.

7.The machine has the characteristics of small and efficient, easy to move and easy to lift, suitable for on-site live operation, can be in any grade of steam turbine or water turbine online clean oil treatment.

After-sales Services

>>>

One year guarantee for product quality. (People damaged parts are charged).

Lifelong maintenance and spare parts supply.

Free design of fixtures as customers requ

ired.