- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

139 KG

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

Pad Printing Machine Ink Cup

-

Pad plate size:

-

150*350mm

-

Closed cup diameter:

-

140mm

-

Application:

-

Tagless

-

Keywords:

-

touch screen PLC pad printer

-

Function:

-

high accurate tampo printing

-

Advantage:

-

touch screen PLC pad printer

-

Operation:

-

touch screen PLC

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KC

-

Voltage:

-

220V

-

Weight:

-

139 KG

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

Pad Printing Machine Ink Cup

-

Pad plate size:

-

150*350mm

-

Closed cup diameter:

-

140mm

-

Application:

-

Tagless

-

Keywords:

-

touch screen PLC pad printer

-

Function:

-

high accurate tampo printing

-

Advantage:

-

touch screen PLC pad printer

-

Operation:

-

touch screen PLC

Samples:

The pad printing process is a special printing technology passed on to China in the 1980s. Because it has a very obvious advantage in printing on the small area and bump surface products, it has made up for the lack of screen printing technology. Therefore, it has developed very fast. In the early 1990s, with the further opening of the Chinese market, a large number of foreign companies with electrons, plastic, gifts, toys, hardware, and automotive accessories were successively entered the Chinese market. Ultra -conventional development, according to incomplete statistics, the application of pad printing technology and screen printing technology in the above industries has reached 27 %, 64 %, 51 %, and 66 %.

There are many characteristics of the pad printing process: the adaptability of the printed matter is wide; there are many types of ink, and the pad printing ink and silk printing ink can basically be universal; the pad printing of different products can be easily completed by replacing fixture and printing block. The deformation of the rubber head has reached special products such as printing bowls, balls; grooves that can be printed, such as the inside of the rice cooker. The pad printer is one of the most widely used special printing machines. When you encounter a conventional machine that you cannot print it, you can consider using the pad printer.

Description:

|

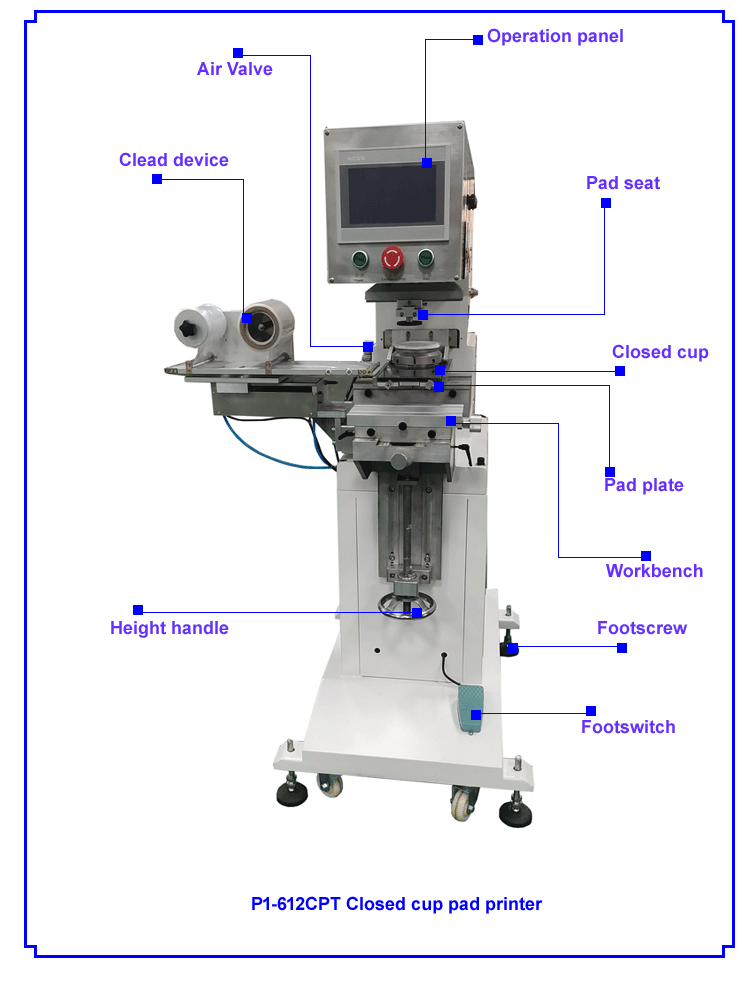

One color pad printer // Structure |

||

|

Working table |

Standard working table with 3-size adjustment |

|

|

Ink supply system |

140mm Closed -type system |

|

|

Plate type and size |

10mm Thick steel plate. |

|

|

One color pad printer// Usage and characters |

||

|

Guide |

|

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

|

One color pad printer // Parameter |

||

|

Technical parameters |

P1-612CPT one color sealed cup pad printer

|

|

|

P1-614CPT one color sealed cup pad printer

|

P1-616CPT one color sealed cup pad printer

|

|

|

Works supply |

|

|

|

Shipment parameter |

|

|

|

||

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

One color pad printer // Advantage |

||

|

Function |

|

|

Details

Structure

Catalogue

1. What is a pad printer?

Pad Printing Machine is the machine, which uses an indirect printing process, it is very suitable for printing irregular surface of small products, make up for the lack of screen printing process, known as the screen printing twin sisters .

2 . The difference between the Closed Cup Pad Printer and open inkwell pad printer

The open ink-tray pad printer uses the ink-tray as the ink supply way, the ink is exposed to the air, the VOC is easy to volatilize to cause the air pollution, the ink-tray pad printers sells mainly to China, Asia, Africa and Eastern Europe and so on the environmental pollution request is not Too high a country;

The closed cup pad printer uses the closed cup as the ink supply way, the ink is enclosed in the cup, the VOC can not volatilize to the air, does not have the pollution to the environment basically, the closed cup pad printers sells mainly to Western Europe, On the environment demanding countries and regions.

3. Shuttle pad printer and Turntable pad printer

Shuttle pad printer is installed shuttle table printing machine, printing back and forth between the colors in the printing, shuttle printing machine can only print one product at a time, more accurate overprint, slower; and Turntable pad printer is installed Rotary table of the printing machine, a 10-station, 16-station, 22-station in various forms. Turntable pad printing machine stations are required to install the same product for printing, faster, no printing shuttle printing machine accurate.

4. Pad printing machine operating system

The ordinary printing machine adopts the microcomputer control system to carry on the control, the high-end pad printing machine uses the PLC to carry on the control, specially the servo control system pad printing machine or the automatic pad printing machine, uses the PLC control system quite commonly.

5. Pad printing machine movement characteristics

Most of the pad printing machine pneumatic control, slower, low cost. With the printing quality and printing speed of the user's high demand in recent years, the use of mechanical control of the pad printing machine more and more common. Pad printing machine automation is the most distinctive trend, the use of automatic feeding system, prepress processing device, servo drive system, automatic printing, drying machine as one of the mechanical and pneumatic motion perfect combination, greatly improving the productivity.

6. How to evaluate the quality of the pad printer

Pad Printing machine technology content is low, more and more enterprises began to produce and sell pad printing machines, pad printing machines of uneven quality, how to evaluate the quality of pad printing machine is essential. As the majority of brand-name pad printing machine is not sold through the network, so, through Alibaba sales of pad printing machines are low-end pad printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the pad printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;