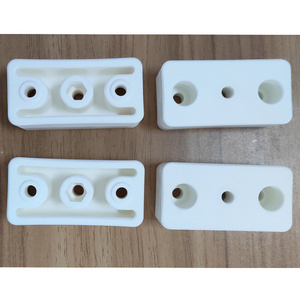

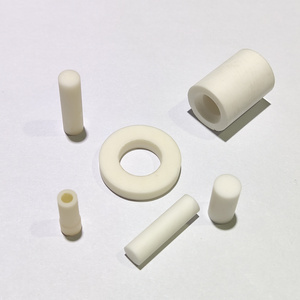

One of the main uses of alumina ceramic is as an insulation material for electrical components. In other applications, it is used for its exceptional strength and corrosion and wear resistance.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Winner

-

Shape:

-

Tubular

-

Color:

-

Light Yellow/White

-

Usage:

-

Industry Usage

-

Size:

-

1-1000mm Custom

-

Feature:

-

High Hardness

-

Advantage:

-

Professional Technical Support

-

Item:

-

Al2o3 Ceramic Parts

-

MOQ:

-

1-10Pcs

-

Purity:

-

95%-99.7%

-

Certificate:

-

ISO9001:2015

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

AL-1

-

Brand Name:

-

Winner

-

Shape:

-

Tubular

-

Color:

-

Light Yellow/White

-

Usage:

-

Industry Usage

-

Size:

-

1-1000mm Custom

-

Feature:

-

High Hardness

-

Advantage:

-

Professional Technical Support

-

Item:

-

Al2o3 Ceramic Parts

-

MOQ:

-

1-10Pcs

-

Purity:

-

95%-99.7%

-

Certificate:

-

ISO9001:2015

Alumina ceramic

Alumina ceramic is a well-known, long-wearing industrial oxide ceramic with high hardness. It is manufactured from bauxite and can be shaped using injection molding, die pressing, isostatic pressing, slip casting, diamond machining, or extrusion. Alumina ceramics have the same sintered crystalline body as sapphire and ruby.

|

Product Name

|

Machining Ceramic

|

|

|

|

|

|

|

|

|||||||

|

Material

|

Aluminum , zirconia, silicon nitride, boron nitride, silicon carbide

|

|

|

|

|

|

|

|

|||||||

|

Length

|

10mm - 1000mm

|

|

|

|

|

|

|

|

|||||||

|

Size

|

According to drawings or samples

|

|

|

|

|

|

|

|

|||||||

|

Torlerance

|

+/- 0.01mm

|

|

|

|

|

|

|

|

|||||||

|

Surface Roughness

|

Ra 0.05

|

|

|

|

|

|

|

|

|||||||

|

Shipping

|

Air Express (DHL/UPS/TNT/ FedEx)

|

|

|

|

|

|

|

|

|||||||

|

Lead time

|

10 - 30 days

|

|

|

|

|

|

|

|

|||||||

|

Properties

|

Units

|

Steatite Ceramic

|

Cordierite Ceramic

|

Mullite Ceramic

|

95% Al₂O₃

|

99% Al₂O₃

|

Zirconia Ceramic

|

Silicon Nitride

|

|

Colour

|

|

White

|

Yellow

|

White

|

White

|

Ivory

|

White

|

Grey

|

|

Density

|

g/cm3

|

2.7

|

1.9

|

2.6

|

3.5

|

3.85

|

6

|

3.2

|

|

Flexural Strength

|

Mpa

|

140

|

30

|

120

|

280

|

340

|

1150

|

600

|

|

Compressive Strength

|

MPa

|

900

|

350

|

500

|

2100

|

2200

|

2500

|

2500

|

|

Max Use Temperature

|

°C

|

1000

|

1200

|

1300

|

1400

|

1650

|

1500

|

1800

|

|

Thermal Condutivity

|

W(m.K)

|

2~3

|

1.3~1.8

|

2~6

|

16~28

|

19~30

|

2.5

|

20

|

|

Thermal Expansion Cofficient

|

10^-6/°C

|

7 ~ 9

|

1.5~3.5

|

5~6

|

6.5~7.5

|

6~8

|

8~10

|

3~4

|

|

ThermalShock Resistance

|

△TC

|

100

|

300

|

150

|

140

|

150

|

250

|

600

|

|

Specific Heat

|

J/kg.K

|

850

|

800

|

900

|

950

|

950

|

500

|

500

|

|

Dielectric Strength

|

KV/mm

|

20

|

—

|

30

|

12

|

10

|

5

|

20

|

|

Dielectric Constant

|

Er

|

6

|

—

|

8

|

9

|

9

|

12

|

6

|

Hot Searches