- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

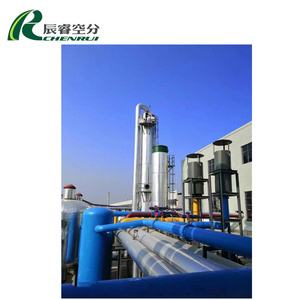

Product name:

-

Cryogenic liquid nitrogen equipment

-

Color:

-

white

-

Function:

-

liquid nitrogen production

-

Package:

-

Export packing or customized

-

Application:

-

Manufacturing Plant,Energy & Mining and other

-

Usage:

-

liquid nitrogen Production

-

Technology:

-

Cryogenic

-

Feature:

-

High Effective

-

MOQ:

-

1

-

purity:

-

high purity

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Weight:

-

13500 KG

-

Dimension(L*W*H):

-

Actual Size

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Cryogenic liquid nitrogen equipment

-

Color:

-

white

-

Function:

-

liquid nitrogen production

-

Package:

-

Export packing or customized

-

Application:

-

Manufacturing Plant,Energy & Mining and other

-

Usage:

-

liquid nitrogen Production

-

Technology:

-

Cryogenic

-

Feature:

-

High Effective

-

MOQ:

-

1

-

purity:

-

high purity

|

Technical parameters of small and medium cryogenic air separation equipment

|

|

|

|

|

|

|

|

|

|

|||||||||

|

model

|

SDON-120/300

|

SDON-180/500

|

SDON-350/900

|

SDON-600/1500

|

SDN-1600/70Y

|

SDON-1000/1100

|

SDON-1500/1500

|

SDON-3200/3200

|

SDQN-5000/5000

|

|||||||||

|

parameter

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Nitrogen Outputting(Nm³/h)

|

300

|

500

|

900

|

1500

|

2000

|

1100

|

1500

|

3200

|

5000

|

|||||||||

|

Nitrogen pressure (MPa)

|

0.02

|

0.02

|

0.02

|

0.02

|

0.02

|

0.02

|

0.02

|

0.02

|

0.02

|

|||||||||

|

Nitrogen purity (%O₂)

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

≤10PPm

|

|||||||||

|

Liquid nitrogen outputting (L/h)

|

120

|

180

|

350

|

600

|

800

|

1000

|

1500

|

3200

|

5000

|

|||||||||

|

Liquid nitrogen pressure (MPa)

|

0.04

|

0.04

|

0.04

|

0.04

|

0.04

|

0.04

|

0.04

|

0.04

|

0.04

|

|||||||||

|

Liquid nitrogen purity (%O₂)

|

99.6

|

99.6

|

99.6

|

99.6

|

99.6

|

99.6

|

99.6

|

99.6

|

99.6

|

|||||||||

|

Air consumption (Nm³/h)

|

1000

|

1500

|

2800

|

3600

|

4600

|

5500

|

8300

|

18000

|

26000

|

|||||||||

|

Air compressor outlet pressure (MPa)

|

0.65

|

0.65

|

0.65

|

0.65

|

0.65

|

0.65

|

0.65

|

0.65

|

0.65

|

|||||||||

1.How can I get the quotation fast?

Tell us your required flow of nitrogen/oxygen ;

The required purity of nitrogen/oxygen ;

The input pressure of your compressed air supply

The pressure of the nitrogen/oxygen used in your application

Tell us your application is helpful to do the recomendation

2.What is the use/application of oxygen and nitrogen?

Ⅰ.Use of oxygen: (application of oxygen plant)

Iron and steel industry: blowing high-purity oxygen into the converter to oxidize carbon, sulfur, phosphorus, silicon and other impurities in iron can greatly shorten the smelting time and improve the quality of steel;

Chemical industry: the use of oxygen in the production of chemical fertilizers from ammonia can strengthen the process and increase the production of chemical fertilizers;

Machinery industry: metal cutting and welding;

National defense industry; liquid oxygen can be used as accelerant for rockets and supersonic aircraft, and combustibles soaked in liquid oxygen can be used as explosives; medical sector: first aid and auxiliary treatment of patients.

Ⅱ.Use of nitrogen (application of nitrogen plant)

Metallurgy, electronics and petroleum industries: as a protective gas;

Chemical industry: synthetic ammonia to produce fertilizer, nitric acid, etc.;

High-tech industry: The low temperature of liquid nitrogen can make some materials obtain superconducting properties.

Food industry: quick-freezing, preservation and preservation of food; medical sector: refrigerant;

3. What is cold box in air separation unit?

An important component in gas separation plants are the so-called “cold boxes”. Cold boxes are (pressure) vessels that hold a gas or liquid at a very low temperature.

4. What is ASU in oxygen plant?

A cryogenic air separation unit (ASU) is a plant that utilizes the distinct properties between the primary components of air to produce highly purified oxygen, nitrogen, and sometimes other gases, such as argon.

5. What is the difference of PSA and Cryogenic plant to produce Oxygen/Nitrogen?

Ⅰ. Adsorption method

Let the air pass through the molecular sieve adsorption tower, and use the molecular sieve to selectively adsorb the oxygen and nitrogen components in the air to separate the air to obtain oxygen.

Ⅱ. Cryogenic rectification (cryogenic air separation plant)

The air is compressed and cooled to make the air saturated and liquefied, and the oxygen and nitrogen are separated by means of rectification by utilizing the difference in the boiling points of the oxygen and nitrogen components, so as to obtain oxygen and nitrogen with high purity.

Cryogenic method is a combination of cryogenic and rectification. It is the most widely used air separation method at present and occupies a dominant position in the oxygen production industry at home and abroad.

Hot Searches