- Product Details

- {{item.text}}

Quick Details

-

Item Name:

-

pu pouring low pressure pu foam robot arm injection molding machine

-

Machine Type:

-

Foam Net

-

Type:

-

energy saving

-

Raw material:

-

Metal

-

Metering pump:

-

Germany/ China

-

Feature:

-

high efficiency

-

Special:

-

increase the roating angle function

-

Weight:

-

1.5-3Ton

-

Power:

-

11kw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Certification:

-

ce

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Item Name:

-

pu pouring low pressure pu foam robot arm injection molding machine

-

Machine Type:

-

Foam Net

-

Type:

-

energy saving

-

Raw material:

-

Metal

-

Metering pump:

-

Germany/ China

-

Feature:

-

high efficiency

-

Special:

-

increase the roating angle function

-

Weight:

-

1.5-3Ton

-

Power:

-

11kw

|

Hello, thanks for your trip here, this is EMM :)

How do you like this product ? please feel free to send us inquiry, it would be great if you can leave your contact information as well, this will make our communication much more effective. |

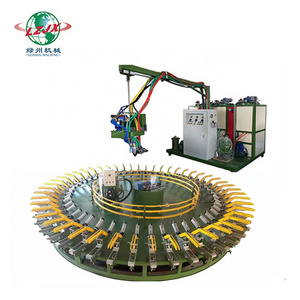

EMM078-A300 pu pouring low pressure polyurethane foam robot arm injection molding machine

EMM078 series High Pressure machine is that our company follows the international’s advanced technological products, The Main parts are imported from foreign countries, technical and safety performance of the equipment has reached the advanced level of the same product of the same period abroad.

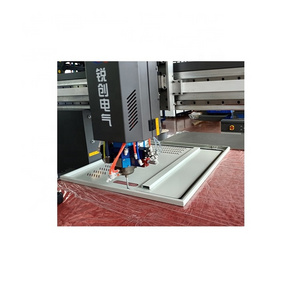

When developing the EMM series high pressure machine, Technology with the "best practices" "plug and play", all of the machine’s parts and module are installed at one frame, component’s pipes short, pressure small, precise at the temperature control, optimization of the control technology, improve the equipment’s reliability and the production’s quantity.

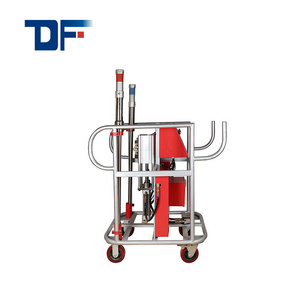

EMM078-A300 pu pouring low pressure polyurethane foam robot arm injection molding machine(Closed loop control system) High pressure machine has 1 POLY. barrel and 1 ISO. barrel, and two metering units drive by independence motors, through changing the pumps output to change the pumps output. This kind of machine is specially used in the polyurethane pouring products.

Product specification

2.1 Type:EMM078-A300 pu pouring low pressure polyurethane foam robot arm injection molding machine

2.2 Suitable foaming system:

2.3 Suitable material viscosity (22°C):

polyol : max. 800-6000 mPs

isocyanate: max. 5-200 mPs

2.4 Pouring output: 150~1530 g/s (1:1), with ratio range adjustable 5:1~1:1

2.5 Pouring program time: 0.5~99.99sec

2.6 Inject the quantity of the procedure:

Manual inject: 9

Automatic inject: 99

2.7 Metering unit: Measurement accuracy≤0.5%

EMM078-A300 pu pouring low pressure polyurethane foam robot arm injection molding machine

|

Component material |

POLY. |

ISO. |

|

Quantity |

1 | 1 |

|

Metering Pump type |

A2VK12(12cc/rev) (Gelanrex) |

A2VK12(12cc/rev) |

|

Shift Motor |

5.5 | 5.5 |

|

Speed(rpm) |

1450 |

1450 |

|

Pump sealing lubricating |

Magnetic coupling (Maintenance-free) |

Magneticcoupling (Maintenance-free) |

Packaging &shipping

|

Packaging Details |

standard export packing |

|

Shipping |

FOB shanghai by sea |

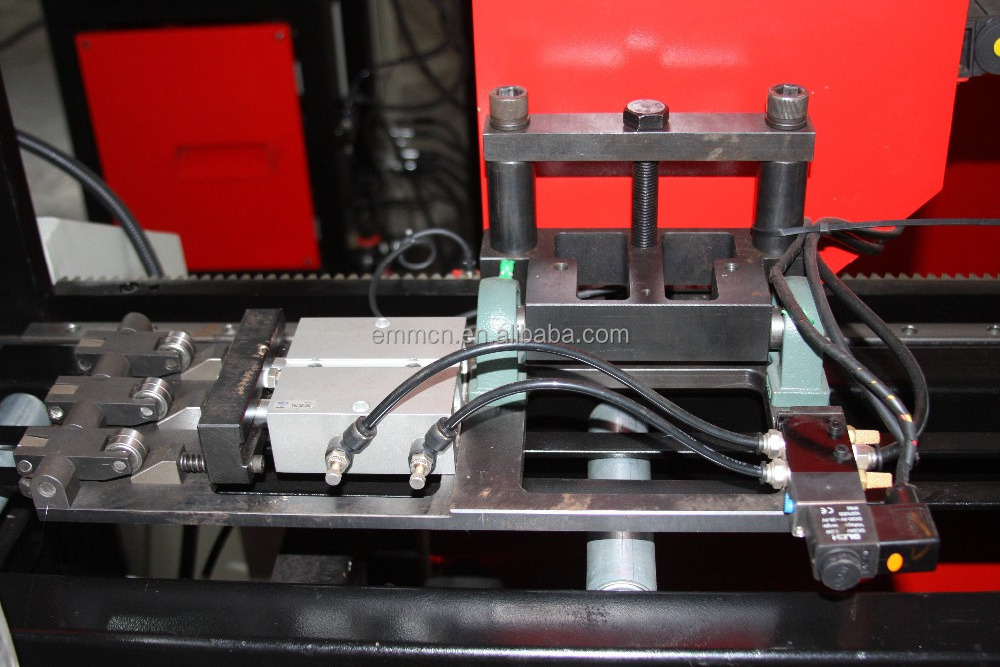

All the parts such as Shift motor , Gear metering pump , Bracket , Coupling is using to metering the components’ flowout.

.Car inside and outside gadget . Heating board

.Keeping warm in refrigerator . Pipe insulation

.Soft and hard foam or self-tegument in furniture . Imitation wood products

. Decorative cornice . Floral foam

. Memory pillow . Foam Mattress

We assist customers in well understanding the product information like features, functions and applications and so on. As for the detailed procuring information or drawings, our professionals will first conduct a careful examination and then recommend the most suitable machines or devise proper schemes for customers. We also provide free samples if necessary.

Service during the Sale

1. We are manned with professional salesmen and technicians to provide the information, technical support and the optimal solutions with high cost performance.

2. Based on the specific requirements of customers and the lead time, we will formulate a rigorous operation process. Through the close cooperation of Commodity Department, Sales Department, Technical Department and the Ocean Shipping Department, we are devoted to timely supplying customers with superior machines.

3. Generally, certain quantity of quick-wear parts will be delivered with the goods. The delivery deadline depends on the specific order, which is usually within 1 to 3 months.

After-sale Service

1. One year warranty is provided.

2. Customers can send photos or samples for our confirmation once the parts are damaged within the one year warranty. If the parts are not damaged by misoperation , we will reply to customers within 48 hours and provide free parts for replacement. Besides, for the parts out of commission and beyond the

warranty, we only charge for the basic costs of parts.

3. We regularly follow up the service condition of products, and timely analyze and copy with the feedbacks. As for the disputes, we will figure out effective actions to reach mutual satisfaction.