- Product Details

- {{item.text}}

Quick Details

-

Type:

-

SF-1.2

-

Effect volume:

-

1.2 m3

-

Power:

-

6.6 KW

-

Capacity:

-

06-1.2 m3/min

-

Dia of impeller:

-

450 mm

-

Weight:

-

1400 kg

-

color:

-

customized

-

Function:

-

separating ores

-

Keywords:

-

flatation machine

Quick Details

-

Weight (KG):

-

800

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

henghong

-

Type:

-

SF-1.2

-

Effect volume:

-

1.2 m3

-

Power:

-

6.6 KW

-

Capacity:

-

06-1.2 m3/min

-

Dia of impeller:

-

450 mm

-

Weight:

-

1400 kg

-

color:

-

customized

-

Function:

-

separating ores

-

Keywords:

-

flatation machine

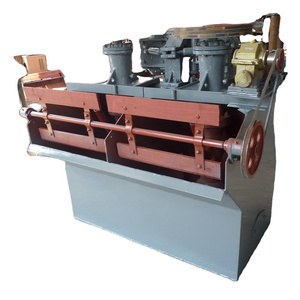

China Flotation Machine For Sale

HengHong flotation machine can be used for many minerals grinding, such as gold, copper, iron and zinc ore and so on. When you find us , you find the best mining machinery manufacturers.

Flotation Machine Introduction

Flotation Machine can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing, scavenging, selection or reverse flotation.In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry, so the separating purpose is finished.

Flotation Machine Working Principle

SF flotation cell adopts creative forward tank, double side blades of water wheels, draft tube and the false bottom device. The slurry in tank takes upper and lower circulation according to the fixed flow mode, which is conducive to suspension of coarse particle.

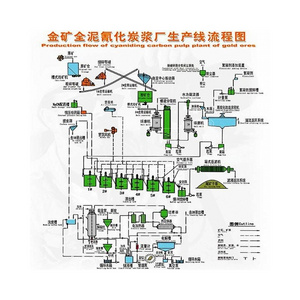

Flotation Machine Application

Flotation cell is widely used for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimed.

Jiangxi Henghong International Mining Machinery Co., Ltd. is the leading company in mining gravity separator machine designing & manufacturing in China. Up to now, we have developed four major product lines, they are mining milling machine, mining classifying separator mining flotation machine and the mining gravity separator. We have three senior engineers and two junior engineers on equipment designing and mining process designing. At the same time, we kept good relationship with some mining research institute and university, such as Jiangxi University of Science and Technology, Ganzhou Nonferrous Metallurgy Research Institute, Hunan Research Institute of Nonferrous Metals, and etc., to improve our designing and production, and also provide technology support for the mining project. With more than 30 years in mining business, we have accumulated enough experience in gold mining plant, tungsten mining plant, wolfram mining plant, tin mining plant, cassiterite mining plant, coltan mining plant, columibte mining plant, iron ore mining plant, black/beach sand mining plant designing, manufacturing, installing, commissioning and training. We could provide

the customized complete mining solution to our customer. Our major overseas market is Africa and Southeast Asia, and our products covers 43 global countries, as more and more customers are aware of our quality products and good service, this number is growing fast.Focus areas:Mining equipent, vibrating feeder, vibrating screen, crusher, ball mill, classifying serparator, leaching tank, flotation machine, gravity seprator, shaking table, spiral chute, jig machine, centrifugal concentrator and other mining equipments.

the customized complete mining solution to our customer. Our major overseas market is Africa and Southeast Asia, and our products covers 43 global countries, as more and more customers are aware of our quality products and good service, this number is growing fast.Focus areas:Mining equipent, vibrating feeder, vibrating screen, crusher, ball mill, classifying serparator, leaching tank, flotation machine, gravity seprator, shaking table, spiral chute, jig machine, centrifugal concentrator and other mining equipments.

1. Pre-sale services:

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

Hot Searches