- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customizable

-

Dimension(L*W*H):

-

111*275*170mm

-

Weight:

-

3 KG

-

Machinery Capacity:

-

customizable

-

Name:

-

Butterfly Valve

-

Material:

-

SUS304

-

Packing:

-

PE Bag

-

Function:

-

Liquild flow control

-

Surface:

-

Polishing 0.4 Micron

-

Gross capaity:

-

1300L

-

Useful capacity:

-

1000L

-

Cooling way:

-

Cooling way

-

Cleaning way:

-

CIP in situ cleaning, with rotary spray cleaning ball

-

Insulation:

-

Polyurethane-thickness: 100mm

Quick Details

-

Place of Origin:

-

Shandong China

-

Brand Name:

-

Hermann

-

Voltage:

-

customizable

-

Power:

-

customizable

-

Dimension(L*W*H):

-

111*275*170mm

-

Weight:

-

3 KG

-

Machinery Capacity:

-

customizable

-

Name:

-

Butterfly Valve

-

Material:

-

SUS304

-

Packing:

-

PE Bag

-

Function:

-

Liquild flow control

-

Surface:

-

Polishing 0.4 Micron

-

Gross capaity:

-

1300L

-

Useful capacity:

-

1000L

-

Cooling way:

-

Cooling way

-

Cleaning way:

-

CIP in situ cleaning, with rotary spray cleaning ball

-

Insulation:

-

Polyurethane-thickness: 100mm

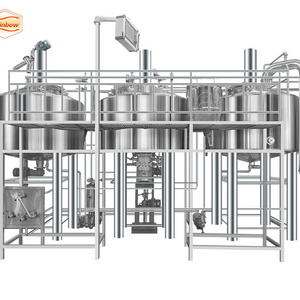

Provide the complete beer production line from brewing equipment to beer package machine

|

1.Malt Milling System

|

Mill machine

|

Stainless steel/Carbon steel

|

|

|

|

Grist case

|

Stainless steel

|

|

|

|

Flexible conveyor

|

Outer PPR or Stainless steel

|

|

|

2.Brewhouse System

|

Mash tun

|

Inner:3mm;outer:2mm

Motor agitation Steam jackets/Electric elements/Fire direct heating |

|

|

|

Lauter tun

|

Inner:3mm;outer:2mm

Rack system; False bottom filter |

|

|

|

Kettle tun

|

Inner:3mm;outer:2mm

Steam jackets/Electric elements/Fire direct heating |

|

|

|

Whirlpool tun

|

Inner:3mm;outer:2mm

Side tangent whirlpool inlet |

|

|

|

Hot water tank

|

Inner:3mm;outer:2mm

Steam jackets/Electric elements/Fire direct heating |

|

|

|

Accessories

|

Mash pump;;Heat exchange plate;Hop back system; Brewhouse Pipes;

|

|

|

3.Fermentation System

|

Fermentation tank

|

Pressure:3Bar;

Inner:3mm;outer:2mm;with insulation; Cooling jackets; |

|

|

|

Accessories

|

Yeast Saving Tank;

|

|

|

4.Cooling System

|

Glycol water tank

|

Inner:3mm;outer:2mm

|

|

|

|

Accessories

|

Chiller; Glycol water pump; Pipes & Valves;

|

|

|

5.CIP System

|

Acid tank

|

Pump; Pipes & Valves

|

|

|

|

Caustic tank

|

|

|

|

|

Trolley

|

|

|

|

|

Accessories of the CIP System

|

|

|

|

6.Control System

|

Automatic/Semi-auto

|

|

|

|

7.Filtering System

|

Candle type diatomite filter/Membrane filter/Bag filter

|

|

|

|

|

Bright beer tank

|

Double-layer with insulation;

|

|

|

8.Filling System

|

Glass bottle line

|

Capacity:800-1200 BPH

Washing heads:8;Filling heads:8;Capping heads:3 Optional: Capacity:1500-2000 BPH Washing heads:16;Filling heads:16;Capping heads:6 |

|

|

|

Canning line

|

Capacity:1000-1500 CPH

Filling heads:12;Capping heads:1 |

|

|

|

Keg system

|

Keg filling machine;Keg washing machine;Keg washing and filling unity machine;

|

|

For more product details, please contact us.

Send Inquiry>>

Shandong Hermann Biological Engineering Co.,Ltd. is an equipment manufacturer focusing on the global biological fermentation industry, with more than 19 years' experience in the field of biological engineering industry, beer (beverage) brewing equipment and filling machine industry, always specializing in the manufacture of high-end equipment. Company is major engaged in beer brewing equiment,providing high-end integrated services from product design,production,processing,installation and technical process reaining for large,mediuu,micro breweries,hotel restaurants,bar brewing enthusiasts.

·

Germany Brau Beviale 2018

·

Shanghai CBC Exhibition 2018

·

Germany Brau Beviale 2019

·

Shangh

ai CBC Exhibition 2019

·

The 101th China Food and Drink Fair

·

2019 HERMANN CUP the 12th Internati-

onal Conference of Beer and Beverage

Technology

·

30T Fermenters

·

Canada 2000L Brewery Plant

·

Shanghai 1000L Brewpub

·

Domestic 3000L Brewpub

·

Netherlands 2000L BBT

·

Argentina 2000L Fermenter

·

KAERA 1000L Brewing System

·

20000L Fermenters in China

Send Inquiry>>

1.How to achieve temperature control?

The PLC or digital dispalyer could control the temperature by connecting with the PT 100 sensor.The brewing tanks with rock wool to keep warm,the fermenters and bright beer tank with PU as cooling jacket to keep cool.

2.Which countries your products are exported to?

Our stainless steel microbrewery equipment are sold all over the world and with related certifications.

3.How to use your machine?

We have paper instructions in English, and we will teach till you do it well.

4.How long is your delivery time?

Usually it takes about 50 working days to manufacture a brewery.Depending on the size of the brewery,the amount of custom designed equipment,our general workload and the way of shipping this period can be shorter or longer.

5.Do you provide after-sales service?

Yes,we could provide after-sales service.We have many professional engineers, they can go to your place and teach your person installation and brewing.

1. Container loading(20GP/40GP/40HQ).

2. Packed with plastic film and iron frame for main tank.Fittings use iron cabinet.

3. Customer's requirements available.

Hot Searches