- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

zhengke

-

Voltage:

-

220-440V

-

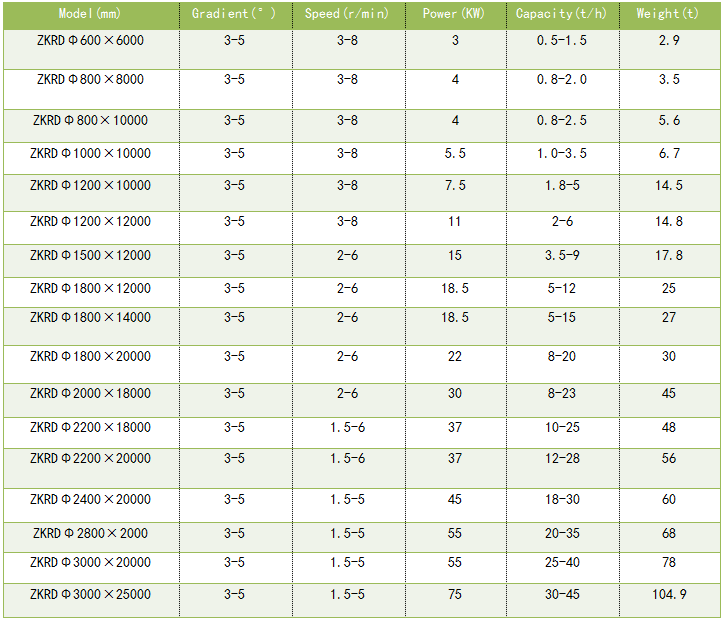

Power:

-

3-75kw

-

Dimension(L*W*H):

-

based on different model

-

Warranty:

-

1 Year

-

Weight:

-

2.9-104.9t

-

Certification:

-

CE,ISO9001-2008

-

Installation:

-

Engineer's Guide

Quick Details

-

Type:

-

Tray Dryer

-

Model Number:

-

ZKRD

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhengke

-

Voltage:

-

220-440V

-

Power:

-

3-75kw

-

Dimension(L*W*H):

-

based on different model

-

Warranty:

-

1 Year

-

Weight:

-

2.9-104.9t

-

Certification:

-

CE,ISO9001-2008

-

Installation:

-

Engineer's Guide

High quality suitable price quartz sand/silica sand rotary dryer/drying machine

Product Description

High quality suitable price quartz sand/silica sand rotary dryer/drying machine is employed to reduce or minimize the moisture content of building meteriasl, coment meterials and other materials. It is widely used to dr raw materials which contains high moisture up to 12% or 15% and more.

High quality suitable price quartz sand/silica sand rotary dryer/drying machine is used for drying coal briquettes, mineral briquettes, iron briquettes fluorite powder briquettes. It is one of the most important equipment in the production line.

Structure of rotary dryer Rotary dry mainly consist of drum barrel, roll ring, wheel gear, lifting board, chain, reduction gears and motor etc parts. It is match with conveyor,dust remover and draught fan etc equipment.

Working Principle

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Often, indirect heated dryers are used when product contamination is a concern.

Company Introduction

Integrating technology and industrial trade,

Zhengzhou Kehua Industrial Equipment Co., Ltd

is a professional manufacturer,

the products have been widely sold in over 20 provinces and regions in China and are exported to Malaysia, Thailand, Philippines, India, Northern Ireland of United Kingdom, United States, Australia, Indonesia, Israel, Egypt, Oman, Moldova, Kazakhstan, South Africa etc.

Certificated of rotary dryer: