1. Packaging:

Packed by standard import & export wooden cases or carton boxes, or by full containers.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Model Number:

-

YG-JD260

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

7100*3000*2200mm

-

Weight:

-

4500 KG

-

Product name:

-

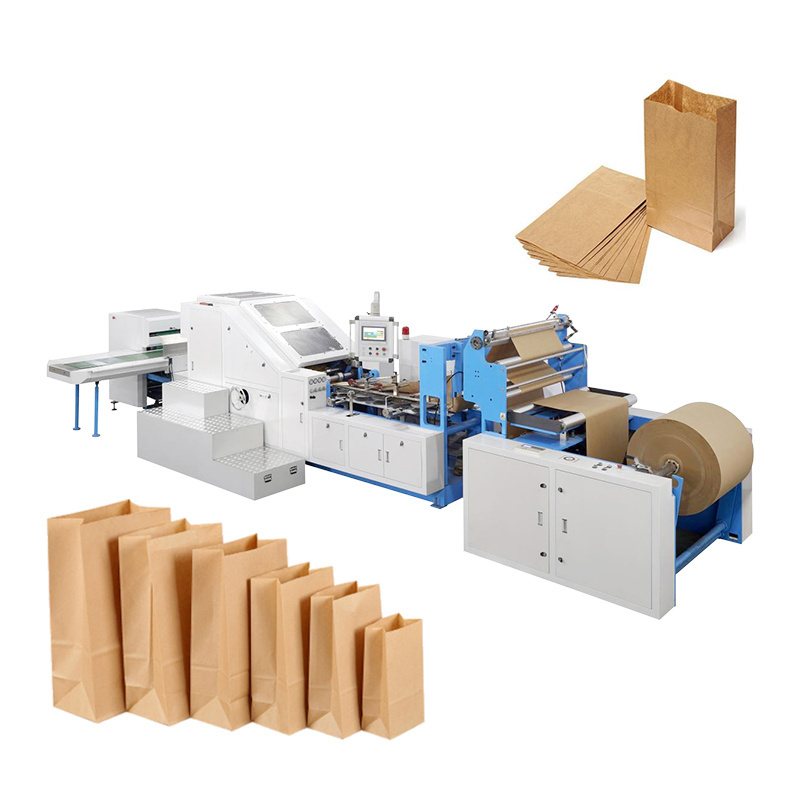

Fully Automatic Paper Bag Making Machine

-

Name:

-

Paper bag making machine

-

Application:

-

Packaging for Food, Clothes, Shoes, etc.

-

Keywords:

-

Bag Marking Machine

-

Function:

-

Paper Bag Producing

-

Speed:

-

50-600pcs/min

-

Key words:

-

High Speed Shopping Bag Making Machine

-

Feature:

-

Advanced Technology

-

Bag Width:

-

50-800mm

-

Type:

-

Paper Shopping Bag Making Machine

Quick Details

-

Machine Type:

-

bag making machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Model Number:

-

YG-JD260

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

7100*3000*2200mm

-

Weight:

-

4500 KG

-

Product name:

-

Fully Automatic Paper Bag Making Machine

-

Name:

-

Paper bag making machine

-

Application:

-

Packaging for Food, Clothes, Shoes, etc.

-

Keywords:

-

Bag Marking Machine

-

Function:

-

Paper Bag Producing

-

Speed:

-

50-600pcs/min

-

Key words:

-

High Speed Shopping Bag Making Machine

-

Feature:

-

Advanced Technology

-

Bag Width:

-

50-800mm

-

Type:

-

Paper Shopping Bag Making Machine

Products Description

Automatic

high speed paper bag making machine

flat square bottom standing V type carry food fed shopping kraft small grocery paper bag making machine

Product performance and usage:

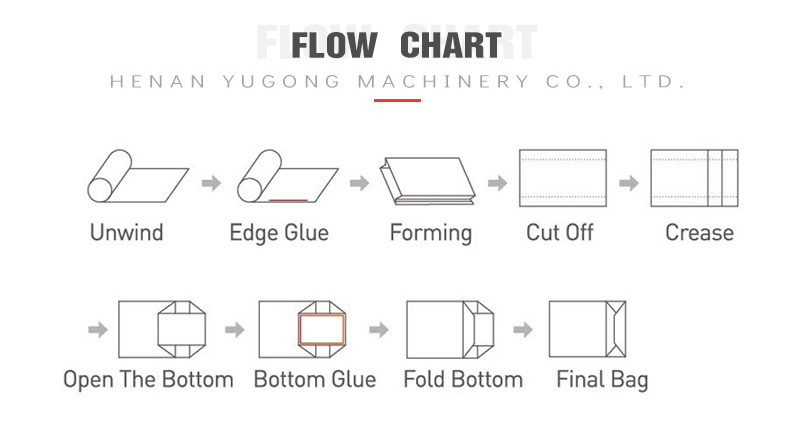

Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper,medico paper and so on, bag making process consist of puncture, side gluing,sidefolding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in onetime. Our machine have advantage of easy operation, high effeciency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment friendly paper bag.

Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as kraft paper, striped brown paper, slick paper, food coated paper,medico paper and so on, bag making process consist of puncture, side gluing,sidefolding, bag forming, cut off, bottom folding, bottom gluing, finish product delivered in onetime. Our machine have advantage of easy operation, high effeciency, more steady, it is an ideal machine for make different kind of paper bag, snack food paper bag, bread paper bag, dry fruit paper bag and environment friendly paper bag.

Product Paramenters

|

Model

|

YG-JD260

|

|

Cutting Length

|

110-460mm

|

|

Bag length (L)

|

100-450mm

|

|

Bag width(W)

|

70-250mm

|

|

Insert size(G)

|

20-120mm

|

|

Paper bag speed

|

30-300pcs/min

|

|

Paper width

|

160-780mm

|

|

Maximum diameter of paper material

|

1000mm

|

|

Inner diameter of paper

|

76mm

|

|

Paper thickness

|

35-80g/m2

|

Main feature:

1. The man-machine interface of Weilun touch screen is adopted, the operation function is clear at a glance, easy to control.

2. Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability.

3. Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size.

4. The loading and unloading of raw material adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic

constant tension control.

5. Brushless servo motor is used to correct the deviation of raw material and reduce the adjustment time of paper roll alignment.

1. The man-machine interface of Weilun touch screen is adopted, the operation function is clear at a glance, easy to control.

2. Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability.

3. Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size.

4. The loading and unloading of raw material adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic

constant tension control.

5. Brushless servo motor is used to correct the deviation of raw material and reduce the adjustment time of paper roll alignment.

Details Images

Product packaging

Automatic high speed paper bag making machine flat square bottom standing V type carry food fed shopping kraft small grocery paper bag making machine

Hot Searches