- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jracking

-

Model Number:

-

radio shuttle rack system

-

Depth:

-

Customized

-

Weight Capacity:

-

500~5000kg

-

Width:

-

Customized

-

Height:

-

Customized

-

Product name:

-

radio shuttle rack system

-

Usage:

-

Warehouse Storage System

-

Color:

-

Customized

-

MOQ:

-

1 Sets

-

Packing:

-

Customers' Request

-

Size:

-

Customized Size

-

Finish:

-

Powder Coated

-

Application:

-

Widely Used

-

Certificate:

-

AS4084-2012 /CE/ ISO/RMI

Quick Details

-

Type:

-

Automated Retrieval

-

Material:

-

Steel

-

Feature:

-

Corrosion Protection

-

Use:

-

Warehouse Rack

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jracking

-

Model Number:

-

radio shuttle rack system

-

Depth:

-

Customized

-

Weight Capacity:

-

500~5000kg

-

Width:

-

Customized

-

Height:

-

Customized

-

Product name:

-

radio shuttle rack system

-

Usage:

-

Warehouse Storage System

-

Color:

-

Customized

-

MOQ:

-

1 Sets

-

Packing:

-

Customers' Request

-

Size:

-

Customized Size

-

Finish:

-

Powder Coated

-

Application:

-

Widely Used

-

Certificate:

-

AS4084-2012 /CE/ ISO/RMI

Product Parameter

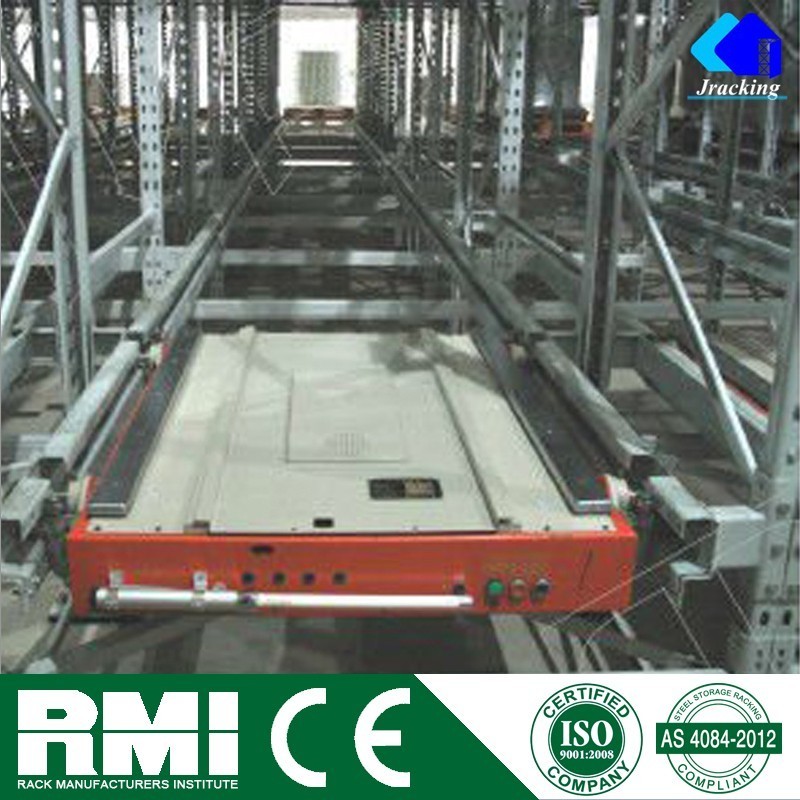

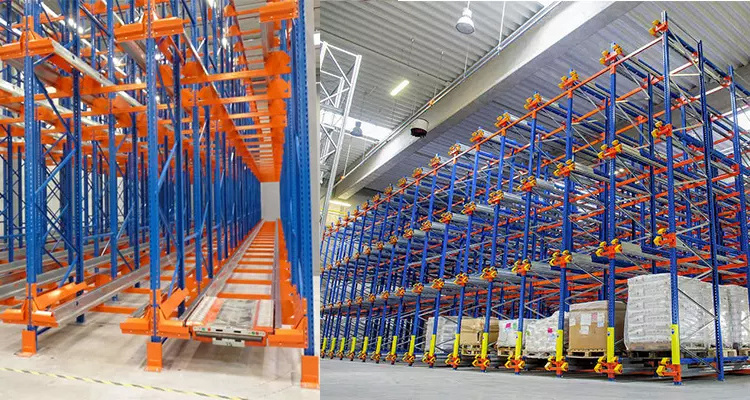

Radio Shuttle System

Jracking Shuttle Racking System is a high-density storage system. The shuttle cart, which is controlled by a wireless remote, takes the pallets in and out of the racking system. The forklift don’t need to enter the storage area. The first pallet’s location at either end is where the forklift loads and unloads the goods.

|

Name

|

Radio shuttle system

|

Material

|

Q235a

|

||

|

Size

|

Customized Size

|

Color

|

Customized

|

||

|

Depth

|

Customized

|

Weight Capacity

|

500~5000kg

|

||

|

Width

|

Customized

|

Height

|

Customized

|

||

|

Finish

|

Powder Coated

|

|

|

||

|

Usage

|

Warehouse Storage System

|

|

|

||

|

Packing

|

Customers' Request

|

|

|

||

|

Certification

|

AS4084-2012 /CE/ ISO/RMI

|

|

|

||

|

Free Sample

|

Available (Delivery Cost on Buyer)

|

|

|

||

|

OEM

|

Available

|

|

|

||

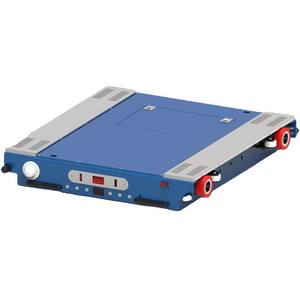

Product Introduction

|

Technical Characteristic

|

|

|

|

|||

|

Running Speed

|

Standard type

|

Low temperature type

|

Advanced type

|

|||

|

|

Vmax_empty:1.2m/s Vmax_full:0.8m/s

|

Vmax_empty:1.0m/s Vmax_full:0.8m/s

|

Vmax_empty:1.5m/s Vmax_full:1.0m/s

|

|||

|

|

The Highest in China

|

The Highest in the world

|

|

|||

|

Loading

|

1.5T (Heavy Load Type 2T) Leading in China

|

|

|

|||

|

Operating Efficiency

|

Closed-loop control of servo system is adopted to reach faster speed, which is 1.5~2 times faster than that in other counterparts.

|

|

|

|||

|

Rapidity & stability

|

Motion parameter and curve of equipment are configured to realize both rapidity and stability.

|

|

|

|||

Direction for use

1. The shuttle has a high precision of parts that move along the aisles between shelves according to computer instructions.

2. The forklift don’t need to enter the storage area. The first pallet’s location at either end is where the forklift loads and unloads the goods.

3. The system could achieve both FIFO and FILO modes.

Description of application effect

1. Can make full use of to 90% of the total area

2. Can store with both last in first out and first in first out system

3. Reduce crashes between forklift and rack, Decreased incidents and maintenance costs

4. Can reach 40meters deep

Installation, Maintenance & Repair

Installation

Jracking will provide detailed installation drawing and on-site installation guidance for your project. Professional technician will adjust and test the shuttle cart for at least one week to ensure the shuttle racking system could work well.

Maintenance

Regular maintenance shall be made in accordance with application manual and maintenance manual.

Jracking’s technician will train the responsible person in your warehouse how to do the routine maintenance.

Lifelong maintenance is provided for guaranteeing customer interests. Jracking is willing to provide lifelong paid service beyond the warranty period. Spare parts for the racking or shuttle cart would be supplied at the most favorable prices.

Repair

One year warranty is promised by Jracking after successful installation and commissioning, excluding natural disaster and man-made damage.

Jracking’s technician will train the responsible person in your warehouse some basic fault conditions and handling methods. If meeting difficult situations, the technician would go and solve the problems on site.

We really appreciate your trust for Jracking and Jracking’s product.

Please kindly keep us posted if you have any suggestion or requirement for our products.

Jracking will provide detailed installation drawing and on-site installation guidance for your project. Professional technician will adjust and test the shuttle cart for at least one week to ensure the shuttle racking system could work well.

Maintenance

Regular maintenance shall be made in accordance with application manual and maintenance manual.

Jracking’s technician will train the responsible person in your warehouse how to do the routine maintenance.

Lifelong maintenance is provided for guaranteeing customer interests. Jracking is willing to provide lifelong paid service beyond the warranty period. Spare parts for the racking or shuttle cart would be supplied at the most favorable prices.

Repair

One year warranty is promised by Jracking after successful installation and commissioning, excluding natural disaster and man-made damage.

Jracking’s technician will train the responsible person in your warehouse some basic fault conditions and handling methods. If meeting difficult situations, the technician would go and solve the problems on site.

We really appreciate your trust for Jracking and Jracking’s product.

Please kindly keep us posted if you have any suggestion or requirement for our products.

Product Categories

Hot Searches