- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HuaRui

-

Model Number:

-

Fiberglass Chopped Strand

-

Surface Treatment:

-

Chopped

-

Processing Service:

-

Chopped Strand

-

Product name:

-

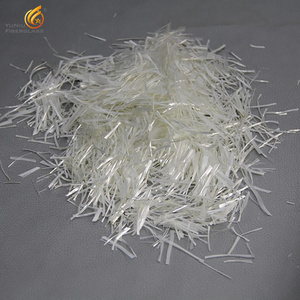

Fiberglass Chopped Strands

-

Advantage:

-

Higher Strength Light Weight

-

Type:

-

SiO2 96%

-

Special Type:

-

Zro2 16.5%

-

Color:

-

White

-

Material:

-

High silica Fiberglass Yarn

-

Feature:

-

Corrosion Resistance

-

Length:

-

6mm

-

Usage:

-

Concrete Cement Mortar Mix

Quick Details

-

Application:

-

construction, industry

-

Technique:

-

Chopped Strand, Chopped

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HuaRui

-

Model Number:

-

Fiberglass Chopped Strand

-

Surface Treatment:

-

Chopped

-

Processing Service:

-

Chopped Strand

-

Product name:

-

Fiberglass Chopped Strands

-

Advantage:

-

Higher Strength Light Weight

-

Type:

-

SiO2 96%

-

Special Type:

-

Zro2 16.5%

-

Color:

-

White

-

Material:

-

High silica Fiberglass Yarn

-

Feature:

-

Corrosion Resistance

-

Length:

-

6mm

-

Usage:

-

Concrete Cement Mortar Mix

|

Product Name

|

|

|

Type

|

High silica fiberglass yarn

|

|

Monofilament diameter (μm):

|

6

|

|

Short cut length (mm):

|

7

|

|

SiO2 content(%):

|

>96

|

|

Zro2 content(%):

|

16.5% (Special Type)

|

【

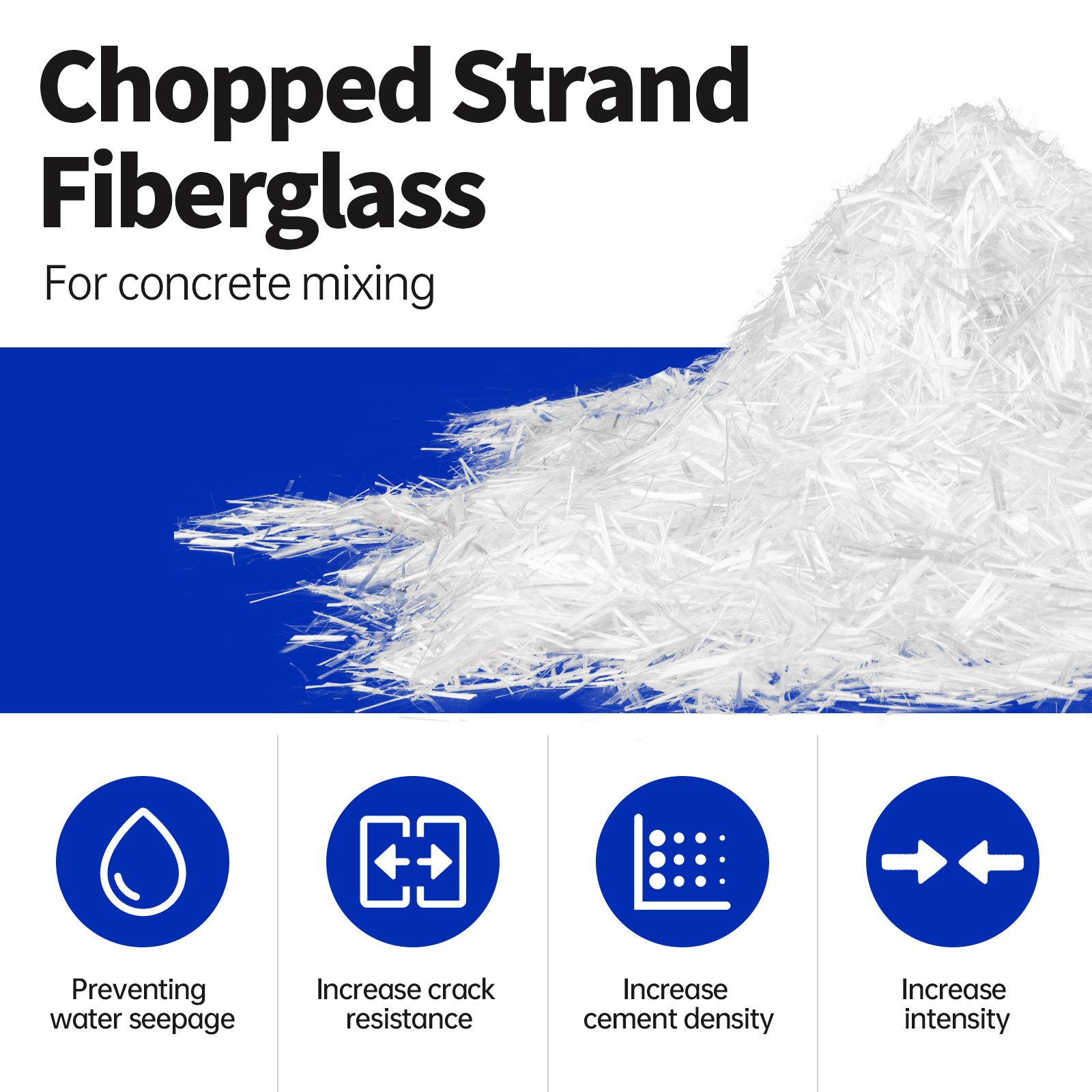

Fiberglass for Concrete

】Mixing fiberglass and concrete mortar to enhance the toughness of the mortar, so to avoid the formation of fine cracks。

【

Impact Resistance

】High-strength fiber filaments are interconnected into a dense net, which holds the cement tightly. Can effectively enhance the impact and earthquake resistance of cement。

【

Tips for use

】Just mix with sand, cement, and fiber. Add 1 pound of glass fiber per 27 cubic inches of concrete, add an appropriate amount of water, and mix well. Note that the mixing time is 30-60 seconds longer than without the fiberglass。

Hot Searches