- Product Details

- {{item.text}}

Quick Details

-

Power:

-

420KW-3000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

100000 kg

-

Product Name:

-

Clinker Cement Grinding Station

-

Color:

-

Customers' Requirements

-

Application:

-

Cement Clinker, Limestone

-

After Sale Service:

-

Engineer Overseas Service

-

Motor:

-

Chinese Brand

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Fuel:

-

Coal, Mazut, Gas etc.

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Advantage:

-

Timely Delivery and Installation, Fast Technical Support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMJO

-

Voltage:

-

220v, 380v, 440v

-

Power:

-

420KW-3000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

100000 kg

-

Product Name:

-

Clinker Cement Grinding Station

-

Color:

-

Customers' Requirements

-

Application:

-

Cement Clinker, Limestone

-

After Sale Service:

-

Engineer Overseas Service

-

Motor:

-

Chinese Brand

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Fuel:

-

Coal, Mazut, Gas etc.

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Advantage:

-

Timely Delivery and Installation, Fast Technical Support

Product Description

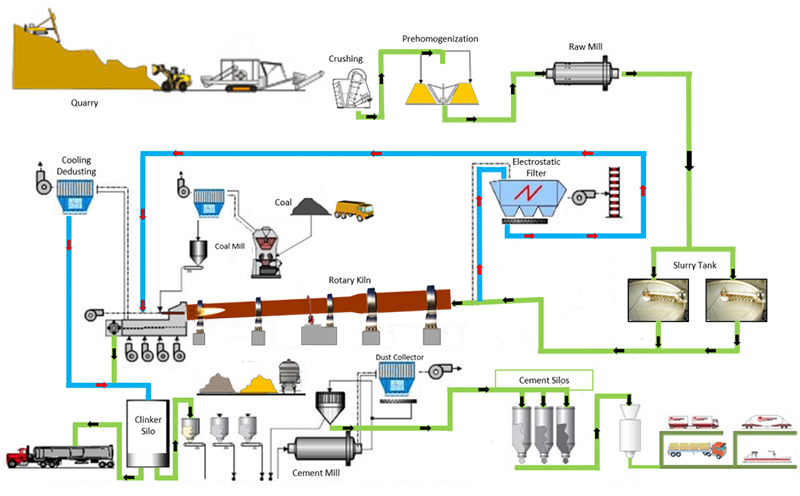

The cement production line is a series of continuous equipment and processes used in a cement plant to produce cement.

It consists of the following main components.

1. Raw material preparation system

The raw materials of cement such as gray stone, clay, sand and so on are crushed, proportioned and mixed to make them meet the production requirements. Common equipments are jaw crusher, hammer crusher, mill, etc.

2. Pre-treatment system

Dry the mixed raw materials to remove the moisture. Commonly used equipment are rotary dryer, tube dryer and so on.

3. Firing system

After drying the raw material powder in the rotary kiln for firing, through the high temperature to melt the raw materials, resulting in cement clinker. Firing system is the core part of cement production.

4. Cooling and grinding system

The clinker from the kiln is rapidly cooled in the cooler, and then the cooled cement clinker is further ground in the cement mill to obtain cement products.

5. Packing and transportation system

The ground cement is transported to the packing system through the conveyor for packing, and then transported to the customers or stored in the warehouse through the transportation system.

Reasonable configuration and matching of cement production line directly affects the quality and efficiency of cement production. A complete cement production line from raw materials to finished cement, need to have dozens of different equipment to complete together.

During the whole cement production process, the composition and proportion of raw materials, as well as the process parameters of calcination and grinding need to be strictly controlled to ensure the production of high quality cement. Modern cement production lines usually adopt automated control systems to improve production efficiency, reduce energy consumption and ensure the safety of the production process.

Cement production line is an industrial production line used to produce cement, which is mainly composed of a series of equipment.

The following is the general equipment composition of cement production line:

Crushing equipment:

Crushing equipment is used to crush raw materials such as limestone, clay and iron ore into small pieces, and common crushing equipment includes jaw crusher and hammer crusher.

Preheating equipment:

Preheating equipment is usually a rotary kiln or precalciner, which is used to preheat the raw materials at about 600℃ to 900℃ to improve their reactivity.

Firing equipment:

The firing equipment is mainly a cement kiln, which is used to calcine the preheated raw materials at a high temperature to make them undergo a chemical reaction and produce cement clinker. During the firing process, the raw materials are gradually lowered in the kiln and slowly rotated inside the kiln.

Cooling equipment:

Cooling equipment is mainly cooling machine, which is used to cool the cement clinker rapidly after firing to stabilize its physical properties.

Grinding equipment:

Grinding equipment is mainly cement mill, which grinds the cooled clinker and appropriate amount of slag, ore and other mixtures into cement powder with suitable fineness.

Fly ash treatment equipment (optional):

For some cement plants, they may also be equipped with fly ash treatment equipment, which is used to treat industrial waste fly ash and make it a raw material to assist cement production.

Packaging equipment:

The final stage of the cement production line is the packaging equipment, which is used to package and load the produced cement for transportation and sale.

It is worth noting that the composition of specific cement production line equipment may vary depending on factors such as the scale of production, process flow, type of raw materials and technology level. The above equipment is just a general example, which does not mean that the equipment composition of all cement production lines is exactly the same.

There are two main methods used in the blending process of cement manufacturing, namely, the dry process and the wet process.

a) Dry process:

1. The calcareous and muddy raw materials are firstly put into the gyratory crusher for crushing to get blocks of 2-5 cm size.

2. The crushed material is put into ball mill or tube mill again for fine grinding to get fine particles.

3. The finely ground material is screened and stored in a hopper.

4. Next, these powdered minerals are mixed in the required proportions to form a dry raw meal mixture which is stored in silos ready to be fed into the rotary kiln.

5. In the rotary kiln, the raw materials are mixed in specific proportions to ensure that the average composition of the final product remains appropriate.

b) Wet Process:

1. Raw materials are first crushed and made into powder form and then stored in silos.

2. the clay is washed in a scrubber mill to remove the organic matter adhering to the clay.

3. the powdered limestone and washed clay are fed into a channel, flowed and transferred to a mill where they are thoroughly mixed to form a paste known as slurry.

4. The grinding process can be carried out in a ball mill or a tube mill or even both.

5. The slurry is then introduced into a collection tank where its composition can be adjusted.

6. The slurry, which contains about 38-40% water, is stored in tanks and is ready for the rotary kiln.

It is important to note that the above process only covers the blending stage of the cement manufacturing process, the actual production process also includes other important steps such as calcination and cooling to obtain the final cement product.

Working Flow

Which is better, the dry process or the wet process?

If we consider the quality and rate then wet process is better and if we consider fuel consumption and time of process then dry process is better. Difference between dry and wet process in table form:

|

Dry Process

|

Wet Process

|

|

1. Mixing of raw material in dry state in blenders.

|

1. Mixing of Raw materials in wash mill with 35 to 50% water.

|

|

2. The dry materials exiting the mill are called “kiln feed”.

|

2. Materials exiting the mill are called “slurry” and have flowability characteristics.

|

|

3. Fuel consumption is low i.e., 100 kg of coal per tonne of cement produced

|

3. Fuel consumption is high i.e., 350 kg of coal per tonne of cement produced

|

|

4. Cost of production is less.

|

4. Cost of production is high

|

|

5. Capital cost is high due to blenders.

|

5. Capital cost (Cost of establishment) is comparatively less

|

|

6. Size of the kiln needed for manufacturing of cement is smaller.

|

6. Size of the kiln needed for manufacturing of cement is bigger.

|

|

7. Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material.

|

7. Raw material can be mixed easily, so a better homogeneous material can be obtained

|

Main Equipment

Cement m

aking machinery

mainly includes crushing equipment, grinding equipment, calcination equipment, dust removal equipment, packaging equipment and preheater, coal mill, cooler, steel silo.

1. Crushing & Proportioning

Primary crushing involves limestone rock fed through large capacity crushers. This reduces the rock to a maximum size of approximately 150 mm. Secondary crushing further reduces this to 75mm or under. Residule material is stacked and reclaimed with a bridge reclaimer in a cross section so that the homogeneous limestone is fed further in the process. This averages the limestone quality.

Primary crushing involves limestone rock fed through large capacity crushers. This reduces the rock to a maximum size of approximately 150 mm. Secondary crushing further reduces this to 75mm or under. Residule material is stacked and reclaimed with a bridge reclaimer in a cross section so that the homogeneous limestone is fed further in the process. This averages the limestone quality.

2. Raw milling & Blending

Crushed particles are ground to 90 microns or less in a closed circuit ball mill with high efficiency separator. The raw meal is transferred to continuous blending silos (CFC) for homogenization ,extracted by load cell hopper for feeding to the kiln preheaters.

Crushed particles are ground to 90 microns or less in a closed circuit ball mill with high efficiency separator. The raw meal is transferred to continuous blending silos (CFC) for homogenization ,extracted by load cell hopper for feeding to the kiln preheaters.

3. Pyro processing

Raw material is heated to over 1,450 °C in a pre-heater tower,then through a pre-calciner and finally to the rotary kiln.

Raw material is heated to over 1,450 °C in a pre-heater tower,then through a pre-calciner and finally to the rotary kiln.

4. Burning

As the material progresses through the kiln, certain elements areremoved in the form of gases. The remaining elements unite to form a new substance (clinker) with new physical and chemical characteristics. Clinker is formed in small marble sized pieces

As the material progresses through the kiln, certain elements areremoved in the form of gases. The remaining elements unite to form a new substance (clinker) with new physical and chemical characteristics. Clinker is formed in small marble sized pieces

5. Cooling, Milling, Storage & Packing

Clinker is discharged from the kiln and the temperature is reduced in grate coolers. The hot air from the coolers is redirected back to the kiln, this saves fuel and increases burning efficiency.

Portland cement, the basic ingredient of concrete, is a combination of calcium, silicon, aluminum, iron and small amounts of other ingredients to which gypsum is added in the final grinding process to regulate the setting time of the concrete.

Our Advantages

Since the establishment of the company in 1995, it has developed into a large-scale enterprise integrating scientific research, production and sales. Our factory can produce cement production line equipment with various outputs, ensuring quality, timely delivery, and timely and efficient after-sales service.

Our senior technical engineers can provide solutions to the problems you encounter through online or quickly arrive at your production site at any time, and our experienced installation team can quickly and efficiently build and install your cement line factory, allowing you Produce cement products that meet the requirements in the shortest time, allowing you to see benefits in the shortest time.

Packing & Delivery

Customer Cases

500TPD Cement Production Line in

Philippines

1000TPD Cement Production Line in

Peru

2000TPD Cement Production Line in Oman

800TPD

Cement Production Line

in

Uzbekistan

Hot Searches