Model:

DLG110

Main motor:

22kw

Cutting motor:

1.1kw

Feeding motor:

0.75kw

Water pump:

0.37kw

Heating:

18kw

Dimension(m):

2.5*0.9*1.8

Net weight:

1260kg

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SBN

-

Voltage:

-

380V/50HZ

-

Power:

-

120kw

-

Dimension(L*W*H):

-

22000x2500x3200mm

-

Weight:

-

5000kg

-

Material:

-

Wheat flour

-

Function:

-

Multifunction

-

Model:

-

DLG 110

-

Capacity:

-

100-120kg/h

-

Export countries:

-

All over the world

-

Processing Types:

-

Automatic

-

Motor:

-

Simens

-

Package:

-

Wooden Case

-

Usage:

-

Food Processing Industry

-

Energy:

-

Electricity Diesel Steam Gas

-

Certification:

-

CE BV ISO9001

Quick Details

-

Production Capacity:

-

100%

-

Type:

-

industrial pasta making machine italy

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SBN

-

Voltage:

-

380V/50HZ

-

Power:

-

120kw

-

Dimension(L*W*H):

-

22000x2500x3200mm

-

Weight:

-

5000kg

-

Material:

-

Wheat flour

-

Function:

-

Multifunction

-

Model:

-

DLG 110

-

Capacity:

-

100-120kg/h

-

Export countries:

-

All over the world

-

Processing Types:

-

Automatic

-

Motor:

-

Simens

-

Package:

-

Wooden Case

-

Usage:

-

Food Processing Industry

-

Energy:

-

Electricity Diesel Steam Gas

-

Certification:

-

CE BV ISO9001

Product Description

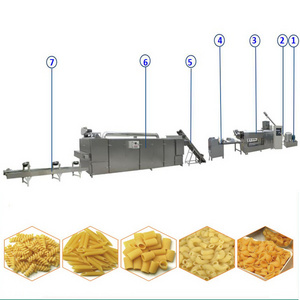

This machine line can use wheat flour as main material to make different shapes pasta , like tube , elbow , screw , shell etc .Equipment configuration is perfect , advanced production technology ; good quality products , simple and reliable operation ; is the ideal equipment to make macaroni .

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts, Field maintenance and repair service

|

|

Local Service Location

|

Egypt, Viet Nam, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Malaysia, Argentina, Algeria, Bangladesh, South Africa, Ukraine, Uzbekistan

|

|

Showroom Location

|

Brazil, Indonesia, Pakistan, India, Thailand, Malaysia

|

|

Condition

|

New

|

|

Type

|

industrial pasta making machine italy

|

|

Production Capacity

|

100%

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

SBN

|

|

Voltage

|

380V/50HZ

|

|

Power

|

120kw

|

|

Dimension(L*W*H)

|

22000x2500x3200mm

|

|

Weight

|

5000kg

|

|

Certification

|

CE BV ISO9001

|

|

Warranty

|

1 Year

|

|

|

Field installation, commissioning and training

|

|

Marketing Type

|

Hot Product 2019

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Motor

|

|

Key Selling Points

|

Competitive Price

|

|

Material

|

Wheat flour

|

|

Function

|

Multifunction

|

|

Model

|

DLG 110

|

|

Capacity

|

100-120kg/h

|

|

Export countries

|

All over the world

|

|

Processing Types

|

Automatic

|

|

Motor

|

Simens

|

|

Package

|

Wooden Case

|

|

Usage

|

Food Processing Industry

|

|

Energy

|

Electricity Diesel Steam Gas

|

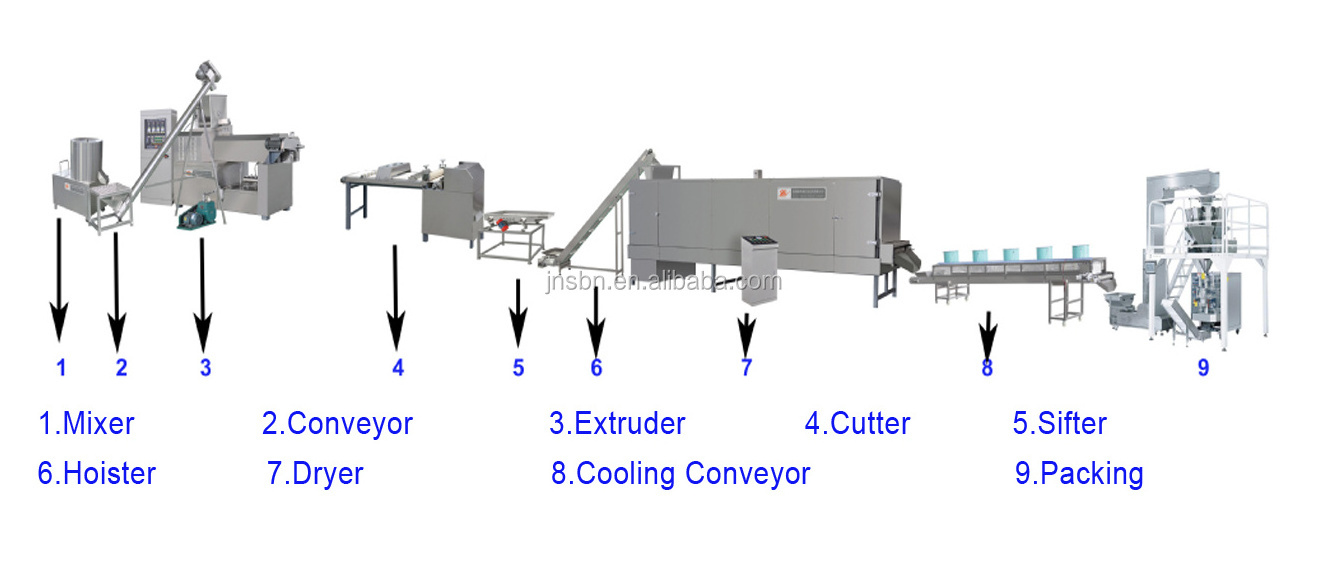

Main equipment

Single screw extruder

Patent:

Vacuum Pump.For the pasta ,the biggest problem is with bubbles and air inside.With the vacuum pump,which can extract air from feeding part,so there will be no any air and bubbles inside.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

Function:

1.Specially decide single-screw system extreude and form the raw material into different sizes and shapes.

2.Controlling system,feeding system,extruding system,heating system, water cooling system, cutting system,lubricating,system,vacuum technology,

Features:

1.Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC.

2.Barrel material is alloy steel, hardness is 52HRC.

3.The gear box has forced lubrication system.

4.All the motor is controled by Inveter, which can save power and protect the extruder.

Adopt American HONEYWELL burner,the proportion of firepower is adjusted, full combustion, high thermal efficiency, no black smoke.

Using Omron temperature control table, Siemens PLC and touch screen control, high temperature accuracy (±1 degree)

Features:

1. Adopts stainless steel punching plate type chain plate structure, which is durable;

2. Both sides of the belt to ensure that the material does not leak sideways;

3. The insulation boards around are all open-door type, with high temperature resistant sealing strips.

4. All bearings are isolated from the high-temperature gas in the box, in a low temperature area.

5. Adopt high-temperature-resistant fan to force the hot air circulation, hot air from bottom to top, even drying, obviously improve the drying efficiency;

6. The bottom plate of the oven adopts a slope shape, which is easy to clean.

7. The mesh belt adopts frequency conversion which is convenient for speed regulation;

8. With distributing machine, the raw materials are evenly distributed on the conveyor belt.

9. Built-in fire-fighting pipeline and sprinkler head, if the material is hot, it can be sprinkled with water.

10. Equipped with humidity adding and measuring device, will automatically open the fan.

Hot Searches