- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TSAUTOP

-

Model Number:

-

Tripod-transport

-

Printing:

-

Water Transfer Printing

-

Main Material:

-

1.5mm SS41# Cold rolled plate punching screw female connector

-

Water Recirculation System:

-

Stainless Pump, AC308V, 3 Phase, 50/60Hz 18kw

-

Activator Sprayer:

-

automatic HVLP spray gun

-

Recycling Fan:

-

High-pressure silent fan, air volume 1900M3/h, 0, 75KW

-

Conveying motor:

-

servo motor 0.4kw HF-KN43J-S100

-

Out size:

-

9*1*0.8m

-

Part A:

-

Continuous film flowing machine

-

Part B:

-

Single-axis reciprocating activator spraying machine

-

Part C:

-

Hydro dipping tank

-

Part D:

-

Tripod Transport Device

Quick Details

-

Method:

-

TSAUTOP Fully Automatic Hydro Dipping Machine

-

Usage:

-

Water Transfer Printing

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TSAUTOP

-

Model Number:

-

Tripod-transport

-

Printing:

-

Water Transfer Printing

-

Main Material:

-

1.5mm SS41# Cold rolled plate punching screw female connector

-

Water Recirculation System:

-

Stainless Pump, AC308V, 3 Phase, 50/60Hz 18kw

-

Activator Sprayer:

-

automatic HVLP spray gun

-

Recycling Fan:

-

High-pressure silent fan, air volume 1900M3/h, 0, 75KW

-

Conveying motor:

-

servo motor 0.4kw HF-KN43J-S100

-

Out size:

-

9*1*0.8m

-

Part A:

-

Continuous film flowing machine

-

Part B:

-

Single-axis reciprocating activator spraying machine

-

Part C:

-

Hydro dipping tank

-

Part D:

-

Tripod Transport Device

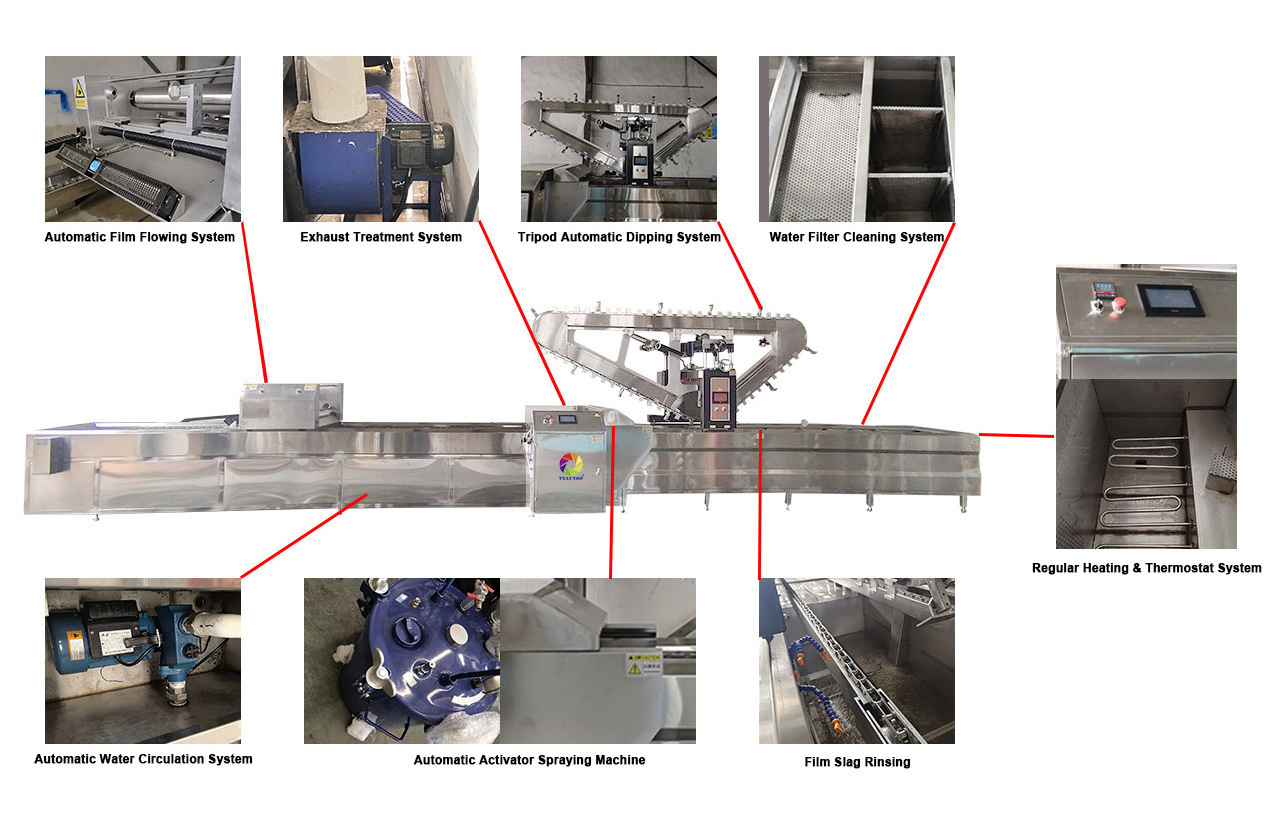

Product Overview

TSAUTOP CE Certification New Design Fully Automatic Tripod-transport Hydro Dipping Machine For Sale

1) This Production Line includes a tripod transfer machine, washing machine ,drying tunnel and paint cabinet;

2) Manual loading on the tripod: the parts are transferred to the transfer room through belt line transmission, which is equipped with automatic electrostatic dust removal device;

3) Film Flowing: The flow film is equipped with an electrostatic dust removal device to reduce the amount of residual static electricity on the surface of the film; the head can move back and forth in the chute to facilitate the adjustment of the soaking time of the film;

4) The method of transporting the film in the tank: the roller adds water to drive the film;

5) Water circulation in the water tank: a small cycle in the water tank, the membrane residue is filtered through six times of filtration, and the filtered water is circulated to the tail for heating, and the water flow is used to ensure the stability of the water temperature and reduce the production of waste water;

6) Spraying activator: The activator is sprayed by a single-axis reciprocating machine, and the side wall of the tank is equipped with exhaust to reduce the concentration and odor of VOCs in the operating area; the spray gun flow, fan shape, air pressure, atomization, etc. can be adjusted externally for easy operation;

7) Film residue filtration: 6-stage filtration;

8) The transfer chain spacing is 50-65cm, which is convenient to adjust the width;

9) The transfer adopts a tripod to automatically enter the water, and the water enters smoothly without shaking or shaking, ensuring that the lines are not deformed;

10) Washing: It is convenient to drain and supply water, the water can be recycled, and the pressure and density of water jets are reasonable;

11) Drying: stable operation, automatic constant temperature control, uniform temperature in the furnace, perfect heat insulation protection system, and energy saving;

Product Paramenters

|

Name

|

Fully Automatic Tripod-transport Hydro Dipping Machine

|

1

|

|

Part A

|

Continuous film flowing machine

|

1

|

|

|

Out size: 9000*1600*1400(mm)

|

|

|

|

Recycling fan:High-pressure silent fan, air volume 1900M3/h, 0, 75KW

|

1

|

|

|

Main material: 1.5mm SS41# Cold rolled plate punching screw female connection production, surface spray-paint treatment

|

|

|

|

cylinder:850mm*φ160mm*10mm 201# Stainless steel round tube precision machining

|

1

|

|

|

Extension shaft:φ50mmStainless steel light circle production, easy to disassemble width adjustable

|

2

|

|

|

Conveying Motor: Geared motor 0.4KW

|

1

|

|

|

Thermostat:Omron

|

1

|

|

|

Inverter: Gtech 0.75Kw

|

1

|

|

|

Contactor: French Schneider LCIE-1810-220AC

|

|

|

|

Touch screen: Xinje 7 inch/TG765-MT

|

1

|

|

|

Electronic valve: smc 24v

|

4

|

|

|

Pneumatic pressure reducing valve: smc

|

4

|

|

Part B

|

Single-axis reciprocating actiator spraying machine

|

1

|

|

|

Conveying motor: servo motor 0.4kw HF-KN43J-S100

|

1

|

|

|

Driver: Drive 0.4kw MR-JE-40A

|

1

|

|

|

Conveying motor2: Servo motor 0.75kw HF-KN43J-S100

|

|

|

|

Driver: drive 0.75kw MR-JE-40A

|

|

|

|

Plc: FX3G-42MT

|

1

|

|

|

Spray gun: automatic HVLP spray gun

|

1

|

|

|

Taiwan Sanhe Pressure Tank: 40L

|

1

|

|

|

Y-axis synchronous belt Track: 40mm*40mm*1000mm

|

1

|

|

|

Base frame: 50mm*50mm*2.0mm stainless steel square tube welded

|

1

|

|

|

Exhaust fan: high-pressure silent fan, air flow 4000M3/h, power: 2.2kw, 380v

|

1

|

|

|

Sealing plate: 201# rusted steel wire drawing board bound

|

1

|

|

Part C

|

Hydro dipping tank

|

|

|

|

(1) Outer Size: 9000mm(L)*1000mm(W)*900mm(H)

|

|

|

|

Tank body: T2.0 201# stainless steel plate tied and welded

|

|

|

|

Tank bracket: 201 # stainless steel pipe welded, with φ14*80 foot cup ±20 adjustable at the bottom.

|

|

|

|

Conveying Chain: Stainless steel C2060 large ball center hole rolling chain with Φ9mm round branches, one round branch every

76.2mm. |

1

|

|

|

Stainless steel C2060 stainless steel crankset φ160mm

|

6

|

|

|

Conveying motor: 0.75kw geared motor (Japan GTR)

|

1

|

|

|

Design speed: 900mm/min (0-3M/min) adjustable

|

|

|

|

Frequency conversion: GE Tech 1.5Kw 23v 1 PHASE

|

|

|

|

Circulating water pump: 1HP internal circulation

|

1

|

|

|

Heater: 316# stainless steel heating tube, power: 6kw/pc

|

3

|

|

|

One active/passive axis each

|

1

|

|

|

Bearing seat: two FT206/FL206 each

|

2

|

|

|

Chain: 38.1 double pitch 201 # stainless steel chain drive

|

1

|

|

|

Track: 304# 50mm*100mm*2mm

|

|

|

Part D

|

Tripod Transport Device

|

|

|

|

size:3400mm(L)*300mm(W)*1220mm(H)

|

1

|

|

|

Angle adjustment: turbine angle regulator (finishing)

|

1

|

|

|

Triangle type: the upper and lower distance governor, Aluminum profiles are machined and formed by CNC;

|

1

|

|

|

Conveying motor: 0.75kw geared motor (Japan GTR)

|

1

|

|

|

Gears: 16 finely machined

|

|

|

|

Conveying motor 2: 0.4kw geared motor (Japan GTR)

|

1

|

|

|

Frequency conversion: SMC 0.75Kw

|

1

|

|

|

Surface milky white spray treatment

|

|

|

|

Up and down lifter

|

1

|

|

|

Left and right angle adjuster

|

1

|

Details Images

Related Products

Our Service

Why Choose Us

OUR FACTORY

CERTIFICATE

FAQ

Q1:How expensive is hydro dipping?

A1:Most hydrographics shops charge around $75 to $80 per wheel, depending on labor costs and

customizations. If hydrodipping is part of a wheel painting package, the cost may be higher.

Q2:What equipment is needed for hydro dipping?

A2:A hydro dip kit is perfect for beginners. The kit includes a hydrographic activator, speed shapes for testing, samples films for testing, and a spray gun system to be used for your top coat or base paint if needed.

Q3:Can I Hydro dip at home?

A3:While there are many companies specializing in hydro dip art for large items (e.g. cars and sports equipment), it's possible to do the process on your own and be creative. Purchase a home hydro dip kit online to apply a design of your choice, with minimal equipment or experience.

Q4:Is Hydro dipping permanent?

A3:While there are many companies specializing in hydro dip art for large items (e.g. cars and sports equipment), it's possible to do the process on your own and be creative. Purchase a home hydro dip kit online to apply a design of your choice, with minimal equipment or experience.

Q4:Is Hydro dipping permanent?

A4:Hydrographics, otherwise known as Hydro dipping, is paint based printing process. Once your item

is painted and hydro dipped, they are protected with an automotive grade clear coat, whilst this is a permanent change, if you ever did change your mind, you could simply paint over it.

is painted and hydro dipped, they are protected with an automotive grade clear coat, whilst this is a permanent change, if you ever did change your mind, you could simply paint over it.

Q5:Is Hydro dipping easy?

A5:When you have a complete hydro dipping kit, the process is easy and fun. You can use the patterns that come with the kit or have a custom pattern applied to the film.You fill a container with water and lay the film on the surface.

Q6:Can you Hydro dip guns?

A6:Because the pattern is printed on water-soluble polyvinyl alcohol film, it can dissolve when sprayed with a chemical agent.

Q7:Is Hydrographics a profitable business?

A7:According to industry estimates, the hydro dipping industry is estimated to be a $1 billion industry with a large chunk of the revenue coming from large scale hydrographic companies, and the smaller percentage coming from individual and small local companies.

Q8:Can you Hydro dip shoes?

A8:Hydro dipping is cool way to customize a pair of vans or other shoes.

Q9:What shoes are best for Hydro dipping?

A9:Popular shoes to hydro dip include Nike Air Max, Nike Air Force 1, and Nike Air Jordans. You can also dip Converse All Stars, classic Vans Slip-Ons, and even Nike Slides. If you have a new pair of shoes you want to customize, or an old pair you want to give new life to, go it!

Q10:What is Hydro dipping activator?

A10:The activator is a chemical that liquefies the ink on the hydro dip film. After you have primed the object and painted it, the item is ready for the film. ... The film is carefully placed on the water surface of a dipping tank. Once the film is hydrated, you add the activator.

Hot Searches