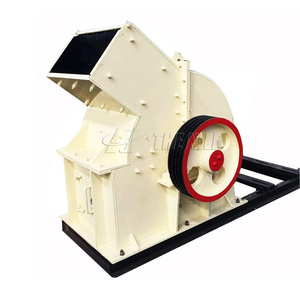

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sinolion

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

1700 KG

-

Warranty:

-

18 month excluding spare parts

-

Marketing Type:

-

New Product 2023

-

Model:

-

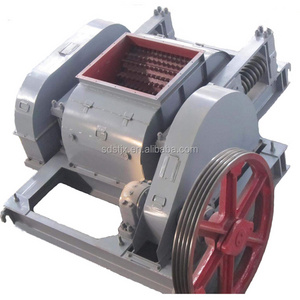

double roll crusher machine

-

Installation:

-

supply manual and send engineer to guide user

-

Feeding size:

-

0-25mm

-

Discharge size:

-

adjustable from 0-40mm

-

Double roller material:

-

manganese steel

-

Motor quantity:

-

2 motors

-

Wearing parts:

-

rollers and v-belt

-

Price:

-

negotiable

-

Color:

-

yellow, white, red, blue, gray( or as client request)

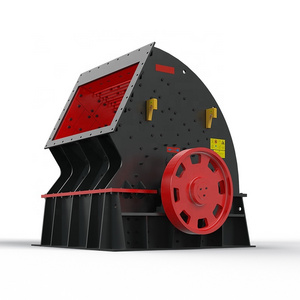

Quick Details

-

Application:

-

chemical industry, stone, ore, glass, coal

-

Capacity(t/h):

-

5-120t/h

-

Place of Origin:

-

China

-

Brand Name:

-

Sinolion

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

1700 KG

-

Warranty:

-

18 month excluding spare parts

-

Marketing Type:

-

New Product 2023

-

Model:

-

double roll crusher machine

-

Installation:

-

supply manual and send engineer to guide user

-

Feeding size:

-

0-25mm

-

Discharge size:

-

adjustable from 0-40mm

-

Double roller material:

-

manganese steel

-

Motor quantity:

-

2 motors

-

Wearing parts:

-

rollers and v-belt

-

Price:

-

negotiable

-

Color:

-

yellow, white, red, blue, gray( or as client request)

Double roller crusher description :

The double roller salt crusher is applied to crushing various medium hardness materials such as limestone, slag, coal etc. in metallurgy, cement, chemistry and other industries for primary and secondary crushing.

Double roller salt crusher working principle:

Double roll crusher adopts two motors, which takes two rollers to rotate reversely by the transmission. When the materials drop on the rollers through the feeding hopper, under the friction of the rollers, they are dragged between the rollers, grinded by the rollers, the crushed materials are pushed rotatorily by the rollers.

The double roll crusher is suitable for crushing medium, high hardness materials in metallurgy, building materials, refractory materials. This series of laboratory double roll crusher is mainly composed of a roller, the roller support bearings, compaction and adjusting device and the drive components. The grain size regulation: wedge or gasket adjusting device is arranged between the two roller, the top of the wedge device with adjusting bolt, when adjust the adjusting bolt will pull up the wedge, the wedge will move the activities roller from fixed wheel.

Double roll crusher technical parameters:

| Model |

Roller diameter (mm) |

Roller length (mm) |

Input size (mm) |

Output size (mm) |

Capacity (t/h) |

Power (KW) |

Weight (t) |

| 2PG-400X250 | 400 | 250 | ≤25 | 0-8 | 5-10 | 5.5x2 | 1.5 |

| 2PG-500X400 | 500 | 400 | ≤30 | 0-10 | 8-20 | 11x2 | 3.2 |

| 2PG-610X400 | 610 | 400 | ≤40 | 0-20 | 13-35 | 15x2 | 4.5 |

| 2PG-610X800 | 610 | 800 | ≤40 | 0-20 | 15-40 | 18.5x2 | 12.25 |

| 2PG-750X500 | 750 | 500 | ≤45 | 0-20 | 15-40 | 18.5x2 | 12.25 |

| 2PG-750X700 | 750 | 700 | ≤45 | 0-20 | 20-50 | 22x2 | 14 |

| 2PG-900X500 | 900 | 500 | ≤55 | 0-40 | 20-50 | 22x2 | 14 |

| 2PG-900X900 | 900 | 900 | ≤55 | 0-50 | 20-70 | 37x2 | 16.8 |

| 2PG-900X1200 | 900 | 1200 | ≤55 | 0-50 | 25-90 | 55x2 | 20.8 |

| 2PG-1200X1000 | 1200 | 1000 | ≤70 | 0-60 | 25-100 | 45x2 | 40.2 |

Laboratory double roll crusher spare parts:

Teeth roller crusher specifications:

| Model |

Feed size (mm) |

Capacity(t/h) |

Power (KW) |

Weight (t) |

||||

| Discharge size(mm) | ||||||||

| 15 | 30 | 50 | 75 | 125 | ||||

| 2PGC-450x500 |

80-150 150-300 |

20 | 35 |

80 50 |

85 | 145 | 11x2 | 4.15 |

| 2PGC-400x600 |

80-150 150-300 |

30 | 50 |

105 70 |

85 | 190 | 15x2 | 4.6 |

| 2PGC-500x750 |

80-150 150-300 |

42 | 68 |

145 85 |

120 | 255 | 22x2 | 5.7 |

| 2PGC-600x900 |

80-150 150-300 |

58 | 80 |

180 100 |

145 | 320 | 30x2 | 7.2 |

| 2PGC-750x750 |

80-200 200-400

|

60 | 80 |

185 90 |

140 | 205 | 37x2 | 11 |

| 2PGC-900x900 |

80-200 200-400 |

70 | 100 |

220 110 |

185 | 380 | 45x2 | 13.8 |

| 2PGC-750x1500 |

80-200 200-400 |

85 | 125 |

205 110 |

180 | 250 | 45x2 | 13 |

| 2PGC-750x1800 |

80-200 200-400 |

120 | 150 |

250 175 |

220 | 380 | 55x2 | 14.6 |

Teeth roller crusher structure:

2PGC series of river stone crusher price mainly consist of roller, the roller support bearings, pinch and adjustparts of the device and the driving device and other components.

1. Pre-sale service:

1) Sinolion will provide production line design, quotation sheet, working sites video, machinery photos, sample testing(gold ore, tin ore , iron ore, tungsten processing in laboratory).

2) Welcome to visit us at any time, we will pick you up.

2. Sale service:

1) Keep clients updated when our company gets advance payment.

2) Confirm production details with clients.

3) Take photos and send all pictures to customers during production.

4) Inspection and testing the product before delivery;

5) Clients are welcome to inspect the equipment when the equipment are ready to delivery.

6) logistics service if needed.

3. After Sale service:

1) Provide foundation drawing to the clients for installation.

2) Besides, our engineers are available to help with installation and workers training.

3) Repairing and maintenance if any problem during the warranty.

4) Spare parts and wearing parts will be offered with production cost in 10 years.