- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50/60hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoli/Aote

-

Dimension(L*W*H):

-

9600x2600x2700mm

-

Weight:

-

9500 KG

-

Function:

-

Laminating film on paper sheets

-

Laminating type:

-

Waterbased and thermal lamination

-

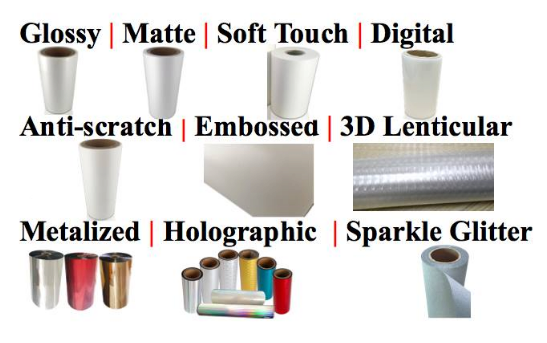

Laminating Material:

-

PET/BOPP/PVC/Metalized film

-

Speed:

-

0-10m/min

-

Feeding way:

-

High speed automatic feeder

-

Heating Way:

-

Electromagnetic heating

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

-

Marketing Type:

-

Major Product

Quick Details

-

Packaging Type:

-

Film, case

-

Packaging Material:

-

Plastic, Wood

-

Driven Type:

-

Electric

-

Voltage:

-

380v 50/60hz

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoli/Aote

-

Dimension(L*W*H):

-

9600x2600x2700mm

-

Weight:

-

9500 KG

-

Function:

-

Laminating film on paper sheets

-

Laminating type:

-

Waterbased and thermal lamination

-

Laminating Material:

-

PET/BOPP/PVC/Metalized film

-

Speed:

-

0-10m/min

-

Feeding way:

-

High speed automatic feeder

-

Heating Way:

-

Electromagnetic heating

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE

-

Marketing Type:

-

Major Product

Product Description

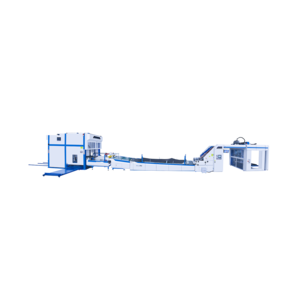

QLFM-1100 series fully automatic vertical lamination machine is designed for waterbased glue and thermal lamination multi-functions. It’s with latest built-in electromagnetic heating device, one-click start, and automatic stacking board exchanging functions. Features high automation, high laminating speed, high accuracy, electrical appliance is centralized by programmable system, touch screen easy to operate.

Lamination Usage

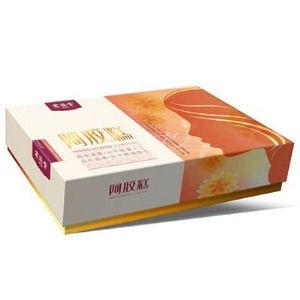

Paper box

Gift box, shoe box, food box, medicine box, express box...

Paper bag

Gift bag, shopping bag, food bag, eco-friendly bag...

Packaging paper

Gift packaging paper, book cover packaging paper...

Book

Poster, magazine, picture, calendar, catalog, leaflet...

Card

Business card, greeting card, post card, advertisement card...

Label

Book label, drink label, food label, sticker...

Product Paramenters

|

Model

|

QLFM-1100A

|

|

Max. Paper Size

|

1000x1080mm

|

|

Min. Paper Size

|

285x350mm

|

|

Recommended Paper Thickness

|

100~500gsm

|

|

Recommended Film Thickness

|

8~25micron

|

|

Max. Laminating Speed

|

100m/min

|

|

Voltage

|

380V 50HZ

|

|

Total Power

|

75kw

|

|

Working Power

|

25~40kw

|

|

Lap Accuracy

|

±2mm

|

|

Regular Pressure

|

5~15Mpa

|

|

Dimension(L*W*H)

|

9600x2600x2700mm

|

|

Packaging Size(L*W*H)

(Wooden Pallet)

(40GP Container)

|

1850x2100x2200(Feeder Unit)

2360x2200x2550(Lamination Unit)

2200x2100x1850(Cutting Unit)

2200x2040x2200(Stacker Unit)

|

|

Total Weight

|

9500kg

|

Details

1. Feeder Part

Equipped with high-speed offset feeder and chain drive non-stop pre-stacking system, it can realize high-speed and non-stop continuous paper feeding and greatly improve the production efficiency. The machine adopts man-machine interactive control buttons for easy operation.

2. Delivery Platform

Equipped with high-precision paper stop front regulator and side regulator, the paper is accurately positioned, and the lap positioning is accurate with small error; The flexibly adjustable paper pressing wheel group can adapt to different sizes of paper to ensure stable paper feeding. At the same time, non-static stainless steel pattern platen is adopted to ensure fast and smooth paper feeding, with nice appearance .

3. Lamination Main Part

The up drying part adopts a large drying cylinder, coated with special material, equipped with groups of built-in heating lamps, supplemented by drying channel thermal circulation system, which can not only greatly reduce the heating time, improve the heating effect and ensure the coating quality, but also save much energy consumption.

The core lamination part adopts a high-precision steel cylinder, equipped with the latest built-in

electromagnetic heating technology. The heating efficiency is higher, the temperature control is more stable, and the coating quality is effectively improved;

The high-precision rubber lamination cylinder adopts high-grade rubber materials, and the surface is smooth and flat to ensure the laminating quality.

electromagnetic heating technology. The heating efficiency is higher, the temperature control is more stable, and the coating quality is effectively improved;

The high-precision rubber lamination cylinder adopts high-grade rubber materials, and the surface is smooth and flat to ensure the laminating quality.

Electrical appliance is centralized by programmable system, with eletromagnetic heating system drive.

4. Glue Coating Part

The high-precision glue coating system can fine tune the coating thickness by controlling the position between the scraper and the roller, ensures uniform coating, reduces glue consumption while ensuring the lamination quality.

The automatic glue circulation system can realize the automatic circulation of glue, which is easier and more convenient for maintenance and cleaning.

The automatic glue circulation system can realize the automatic circulation of glue, which is easier and more convenient for maintenance and cleaning.

The air shaft is marked with scale, to load film easily. There is an inflatable gas gun for air shaft; The tension of the film roll can be easily adjusted through the tension controller; The electric waste film winding rack assists in winding excess waste film.

Equipped with 10 inch color human-computer interaction touch screen, the interface is simple and easy to operate. The operator can view the working state of the machine at any time through the display screen, and easily set and adjust various parameters; A new NC one-click-start button is added to facilitate the operator to run the machine quickly.

5. Slitting Part

Adopt disc knife, coordinate with pneumatic roller separating system, can slit BOPP and OPP film perfectly.

(If you use PET or metalized foil, there is Chain knife and Hot knife cutting device optional)

(If you use PET or metalized foil, there is Chain knife and Hot knife cutting device optional)

The paper anti-curvature mechanism can solve the problem of curling that may occur after lamination of thin paper, so as to make the paper more flat and facilitate the subsequent slitting and stacking.

6. Stacker Part

After slitting, the paper can be smoothly received even if the paper is very thin through the corrugating mechanism; The fan group provides downward thrust to prevent paper from flying out of the receiving stack when the running speed is too fast .

The automatic paper stacker can stack single or multiple sheets at the same time. The paper is stacked neatly, which is convenient for transportation and subsequent processing; The stacked paper can be counted automatically through the infrared sensor.

The stacker is equipped with latest automatic stacking board exchanging technology, it can automatically output and receive paper when the paper stacking capacity is almost full, which greatly saves the man hours required for manual board exchanging, and significantly improves the work efficiency.

Related Products

Part of Configurations

|

Touch Screen

|

China Flexem

|

|

Encoder

|

Japan Omron

|

|

Inverter

|

China Kewo

|

|

AC Contactor

|

France Schneider

|

|

Intermediate Relay

|

France Schneider

|

|

Push Button Switch

|

China Yijia

|

|

Small broken Fuser

|

China Chint

|

|

Programming Controller

|

Chinese Taiwan Delta

|

|

Servo Drive

|

Chinese Taiwan Delta

|

|

Motor 5.5KW

|

China Dongfang

|

|

High speed Feeder

|

China Runze

|

|

Converters

|

France Schneider

|

|

Digital Control Devices

|

Chinese Taiwan Delta

|

Packing&Shipping

Regularly adopts moisture-proof and shock-proof fumigation-free strong wooden box packaging which is suitable for long-distance road transportation and various types of weather condition.

Company Introduction

Ruian Aote Packaging Machinery Co, Ltd.

processes near twenty years of experience in manufacturing lamination machine of post-press equipment. Our strength in researching, designing, manufacturing and servicing process has developed us as one of top professional company in China. Our strong technical force, high-quality products, "Aoli" trademark and perfect after-sales service have won the trust of users at home and abroad.

FAQ

1. What's your delivery time?

Regularly within 30 days upon production schedule after receved payment. (upon confirmation)

2. After-sale service and warranty?

We provide 1 year warranty period. During the period, we supply the spare parts in free for replacement in case of any quality problem. And you will enjoy life time technical support by our professional after-sales team.

3. D o you have engineer available for installation, training and test to my factory?

Don’t worry, we have installation service. All the machines have been adjusted and tested well in our workshop before delivery. If you require, our engineer will come to your factory for technical support. But you shall pay extra installation cost upon final confirmation.

(Except for special period and circumstances)

4. Any certifications?

Yes all the machines have passed

ISO9001

and

CE

certification. And we have patents about chain knife, heating roller and powder cleaning.

We have been rated as "Reliable Products", "Honoring Contract, Keeping Promises” , "Enterprise Integrity", "AAA grade credit enterprise" by our

government.

Hot Searches