- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dazhen

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Vary

-

Weight:

-

500 KG

-

type:

-

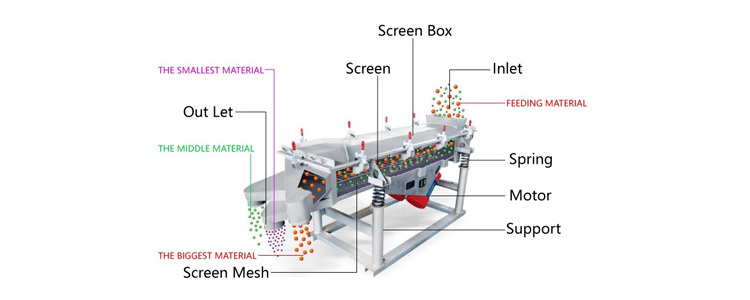

linear vibrating sieve shaker

-

application:

-

scrap metal recycling

-

deck:

-

2-3

-

screen mesh:

-

as required

-

construction material:

-

mild steel or stainless steel

Quick Details

-

Type:

-

linear vibrating sieve shaker

-

Marketing Type:

-

linear vibrating sieve shaker

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dazhen

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Vary

-

Weight:

-

500 KG

-

type:

-

linear vibrating sieve shaker

-

application:

-

scrap metal recycling

-

deck:

-

2-3

-

screen mesh:

-

as required

-

construction material:

-

mild steel or stainless steel

scrap metal recycling equipment linear vibrating sieve shaker

for aluminum shavings magnesium turnings metal powder

Hot Searches