- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Three system

-

Computerized:

-

Yes

-

Gauge:

-

7 GG, 12 GG, 14 GG, 16 GG, 9 GG, 5 GG, 10GG, 8GG, 3-5-7 multi-gauge, 8-10-12 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Arrow star

-

Power:

-

1.5 W, AC220v/380v 50/60HZ

-

Weight:

-

1250 KG

-

Dimension(L*W*H):

-

2850*1100*1800 mm

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

Fully Jacquard Sweater Knitting Machine

-

System:

-

single carriage with double system

-

Knitting Width:

-

52 inch (36-80 inch all available )

-

Brand:

-

ARROW STAR

-

Model:

-

AS52-2S

-

Running speed:

-

1.4m/S

-

Motor:

-

Servo Motor

-

Product Name:

-

Arrow star computerized sweater knitting machine price

Quick Details

-

Type:

-

Crochet

-

Production Capacity:

-

100pcs/day

-

Knitting Style:

-

Warp

-

Knitting Method:

-

Three system

-

Computerized:

-

Yes

-

Gauge:

-

7 GG, 12 GG, 14 GG, 16 GG, 9 GG, 5 GG, 10GG, 8GG, 3-5-7 multi-gauge, 8-10-12 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Arrow star

-

Power:

-

1.5 W, AC220v/380v 50/60HZ

-

Weight:

-

1250 KG

-

Dimension(L*W*H):

-

2850*1100*1800 mm

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

Fully Jacquard Sweater Knitting Machine

-

System:

-

single carriage with double system

-

Knitting Width:

-

52 inch (36-80 inch all available )

-

Brand:

-

ARROW STAR

-

Model:

-

AS52-2S

-

Running speed:

-

1.4m/S

-

Motor:

-

Servo Motor

-

Product Name:

-

Arrow star computerized sweater knitting machine price

Product Description

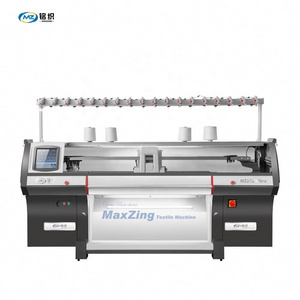

AS52-3S three system sweater flat knitting machine

It applies unique cam and needle bed to achieve transfer,tuck,eyelet stitch,jacquard,apparent shape, hidden shape and other regular pattern knitting functions.It can knit basic stitch like plain stitch,rib fabric,links and links,interlock stitch,etc.irregular multi-color jacquard,twist flowers weft organization,aran,cord weave,racked stitch,cable,intarsia,etc.

It is suitable to use synthetic,wool,acrylic,mixed fiber,yarn material etc to knit ready-made cardigan,hat,gloves,scarf and

accessories of cloth.Machine through subsection control and adjustable pulling rev,it can complete complex knitting and improve production efficiency.

It is suitable to use synthetic,wool,acrylic,mixed fiber,yarn material etc to knit ready-made cardigan,hat,gloves,scarf and

accessories of cloth.Machine through subsection control and adjustable pulling rev,it can complete complex knitting and improve production efficiency.

Products specification

|

Model

|

Knitting width

|

Machine Size (CM)

|

|

Weight (KG)

|

|

|

AS36S-3

|

36 inch

|

2050X750X1750

|

|

around 490

|

|

|

AS52S-3

|

52 inch

|

2450X750X1750

|

|

around 590

|

|

|

AS60S-3

|

60 inch

|

2650X750X1750

|

|

around 650

|

|

|

AS66S-3

|

66 inch

|

2800X750X1750

|

|

around 700

|

|

|

AS72S-3

|

72 inch

|

2950X750X1750

|

|

around 750

|

|

|

AS80S-3

|

80 inch

|

3150X750X1750

|

|

around 800

|

|

Details Images

Advantage of our flat knitting machine

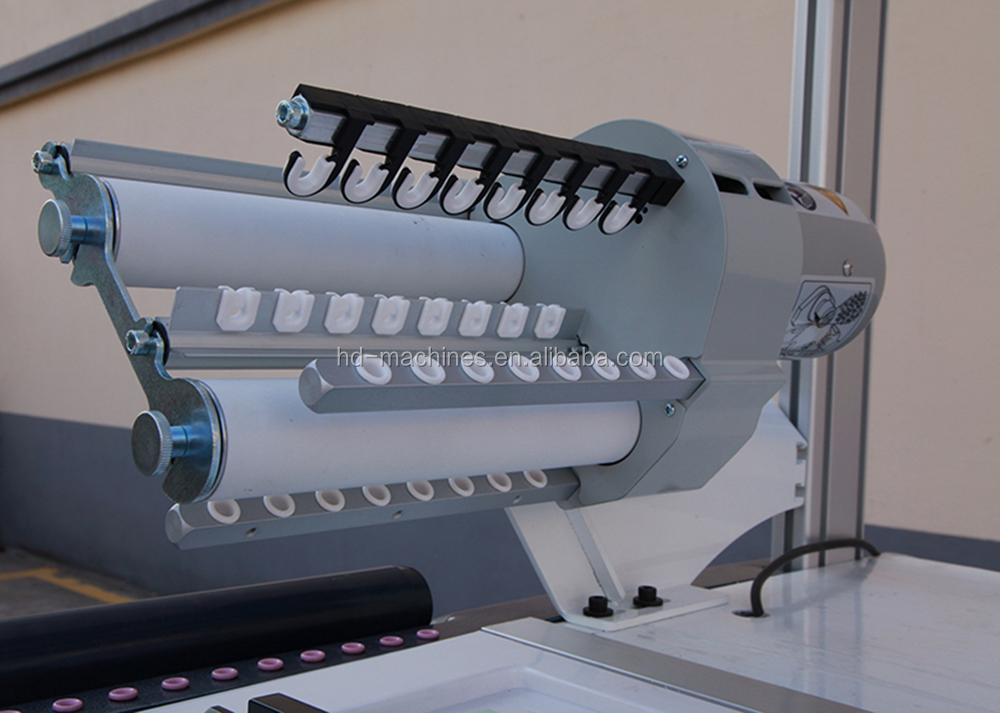

Positive feed yarn device

Positive yarn feed device could reduce resistance while yarn is moving , suit for fabrice with lace of elasticity and brittle fabric

to make the fabric even and improve knitting efficiency.

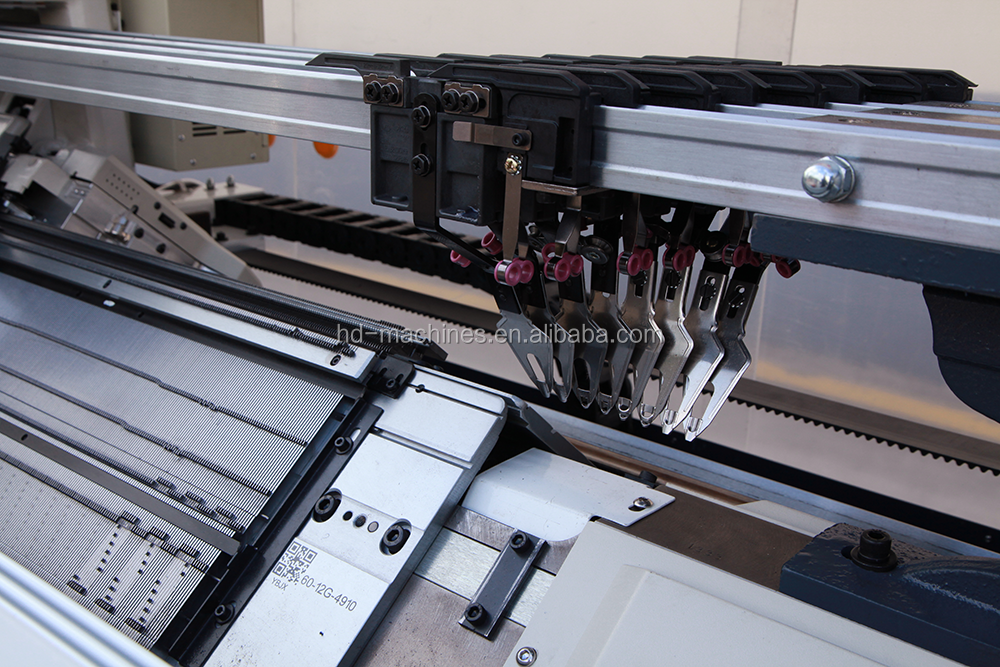

Ultra-small Carriage

Further optimize the size of the machine carriage ,reduce the carriage return distance and improve the efficiency .

16 yarn carriages

The 16 yarns can be used by any weaving system and can be switched at any position. According to different knitting speed the control program can automatically adjust the position of the yarn nozzle.

Plus wide transmission belt

Specifical design double row synchronizing transmission belt let the machine with more stable running performance .

Motorized inversion bar & Tight handing head

The carriage inversion bar driven by motor ,carriage return is more accurate

Tight is controlled by the motor ,to achieve different degrees of tight tuck,ranging from 0 to 80 .

Auto oil system

Machine have fully automatic refueling system .Self-determind auto oiling when time up automatically refueling and lubrication the jack and spring needles on the needle bed ,avoide maintance problem ,increase machine serive life

LCD Touch screen

Humanized design control interface large memory capacity, can store about 1000 patterns, for tens of thousands of lines of complex patterns can also be read quickly without waiting. Stable performance make the operation more convenient, easy to learn ndunderstand.

Japanese MINEBEA Stitch motor

Adopt Japanese Minebea increase torque stitch motor . With Dynamic stitch function ,using high speed stepping motor multi-segment stitch function can be achieved in one course .

Servo Motor

Using cani control ,can achieve the rapid return and direction changing of the machine carriage ,accurate positioning ,smooth conmutation .

Product Paramenters

|

SPECIFICATION, GAUGE AND TECHNICAL PARAMETE

R

|

|

|

|

|

||||

|

Gauge

|

3G,3.5G,5G,7G,8G,9G,10G,12G,14G,16G,3-5-7G multi-gauge

|

|

|

|

||||

|

Knitting width

|

36,52,56,60,66,68,72,80,100,120 inch

|

|

|

|

||||

|

Knitting system

|

Single carriage with three system

|

|

|

|

||||

|

Knitting function

|

Knit, miss, turk, transfer, pointel, intarsia, jacquard, apparent or hide shaping and other regular or irregular patterns

|

|

|

|

||||

|

Knitting speed

|

Controlled by sevro-motor with 32 sections optional, max speed reach 1.2M/S

|

|

|

|

||||

|

Racking

|

Controlled by sevro-motor racking within 2 inches and with fine adjusting function

|

|

|

|

||||

|

Needle selection

|

Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector.

|

|

|

|

||||

|

Stitch density

|

Controlled by stepping motor, 32 section stitch selectable adjustable scope supported by subdivision technology: 0-650, the stitch

of the knitwear can be accurately controlled. |

|

|

|

||||

|

Transfer

|

Combined design, single or double cam system all can transfer together or separately. Also one cam do transfer, another cam system

for knitting, which will achieve high production |

|

|

|

||||

|

Sink system

|

controlled by stepping motor, adjustable to different knitwear, up to be various results of shaping and patterns.

|

|

|

|

||||

|

Comb system

|

Grip or knock-over the yam reliably (Optional)

|

|

|

|

||||

|

Cutters and Grippers

|

Include 2 cutters and 4 grippers, controlled by 6 motors respectively(Optional)

|

|

|

|

||||

|

Take-down system

|

Computer programs instruction,stepper motor control and 32-stagetension selection with an adjustable range between 0-100

|

|

|

|

||||

|

Color-changing sytem

|

2X8 yarn feeders at the single side of 4 guide rails, shiftable on any needle position

|

|

|

|

||||

|

Protection system

|

The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle

breakage, error programming occur, also set up the safety auto-lock protect device. |

|

|

|

||||

|

Control system

|

1. LCD industrial display, Can display various parameters, which can be adjustable during operation.

|

|

|

|

||||

|

|

2. USB memory interface,System memory 1G.

|

|

|

|

||||

|

|

3. Free design system is visual and easy to understand and software upgrade free of charge.

|

|

|

|

||||

|

|

4.Support multi-language operation as Chinese and English, Spanish, Russian etc.

|

|

|

|

||||

|

Power

|

Single-phase 220V/three-phase 380V,adopt advanced CMOS technology, having memorizing function at power shock stop.

|

|

|

|

||||

Knitting Samples

Our samples room

Hot Searches