- Product Details

- {{item.text}}

Quick Details

-

Material:

-

wooden

-

Weight:

-

2200kg

-

Size:

-

1600*1800*1300

-

Power:

-

22kw

-

Keywords:

-

slop oil sludge oil water separator

-

Name:

-

LWS 3 phase slop oil sludge water separator

-

Title:

-

three phase decanter centrifuge

-

Drum diameter:

-

420mm

-

Drum length:

-

1720mm

-

speed:

-

0-3300r/min(adjustable)

-

Capacity:

-

≥7T/h

-

material:

-

304/316L stainless steel

-

control type:

-

PLC control

-

operation:

-

automatical continuous operation

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Indonesia, Pakistan, India, Russia, Thailand, Ukraine

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

Quick Details

-

Applicable Industries:

-

waster water, crude oil

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fivemen

-

Material:

-

wooden

-

Weight:

-

2200kg

-

Size:

-

1600*1800*1300

-

Power:

-

22kw

-

Keywords:

-

slop oil sludge oil water separator

-

Name:

-

LWS 3 phase slop oil sludge water separator

-

Title:

-

three phase decanter centrifuge

-

Drum diameter:

-

420mm

-

Drum length:

-

1720mm

-

speed:

-

0-3300r/min(adjustable)

-

Capacity:

-

≥7T/h

-

material:

-

304/316L stainless steel

-

control type:

-

PLC control

-

operation:

-

automatical continuous operation

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Indonesia, Pakistan, India, Russia, Thailand, Ukraine

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

LWS 3 phase decanter petroleum/ slop oil sludge oil water separator for oil water sludge separation

the centrifugal force, which effectively prevents the phases mixture and incomplete separation. Ordinary three

Material: high quality stainless steel

Bearing: SKF brand. A special selection and arrangement of bearings provides for long life and exceptional reliability

Wear protection: carbide sheets of spiral feeder and replaceable alloy sleeves of drum outlet and spiral feeder outlet

Feature of 3 phase industrial decanter centrifuge

1. Robust quality

2. Outstanding separation effect

3. Wide usage in the fish oil and fishmeal field

4. Corrosion resistant an resistant key parts

5. Flexible length-to-diameter model for customerized.

6. Famous and reliable electrical components

| Feature |

The decanter centrifuge can be adjusted to suit individual requirements by varying:

1. Bowl speed to ensure the exact relative centrifugal force required for optimized separation.

2. Differential speed, for optimized balance between liquid clarity and solids discharge capacity.

3. Pond depth in the bowl for optimized balance between liquid clarity and solid dryness.

| Application |

The machine is widely used in industries as municipal and industrial waste water treatment, food processing, pharmaceuticals and chemicals, etc.

1. Solid phase dehydration: dehydration effect for processing materials of solid particles.

2. Particle size classification: used in the removal of material of large diameter solid particles.

3. Liquid clarification: used for removing solid particles in the suspension liquid are clarified.

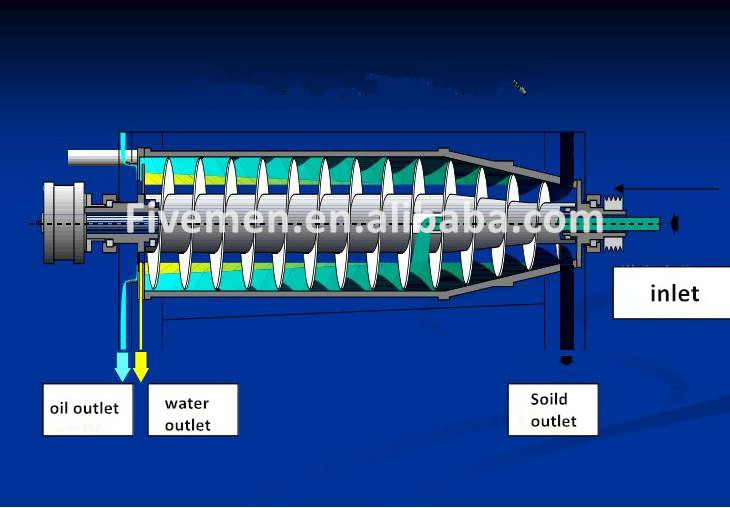

| Working principle |

Separation takes place in a horizontal cylindrical bowl equipped with a scroll conveyor. The processing material is fed into the bowl through a stationery inlet tube and is smoothly accelerated in the accelerate chamber. Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl.

| Technical parameters |

|

Type |

Bowl diameter ( mm ) |

Bowl length/ Bowl diameter |

Bowl speed (r/min) |

Main Power ( Kw ) |

|

LWS355 |

355 |

3.3-4.5 |

4000 |

15-18.5 |

|

LWS420 |

420 |

4.1 |

3600 |

22 |

|

LWS500 |

500 |

4.2 |

3000 |

30 |

|

LWS530 |

500 |

4.2 |

3000 |

30 |

|

LWS580 |

580 |

4.1 |

2800 |

45 |

|

LWS620 |

620 |

4 |

2800 |

45 |

|

Note: In case of differences between the table and the user manual, the latter shall prevail. |

||||

|

Main Parts |

Application site