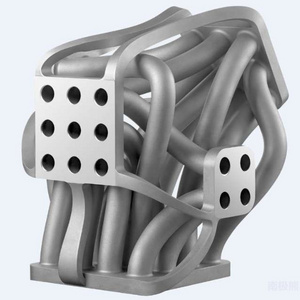

Designers often chose DMLS for its ability to produce all-in-one metal assemblies and highly precise metal parts with complex features like internal supports and lattices. DMLS does not have upfront setup or tooling costs, making it an affordable option for fully dense metal parts, with the design freedom of additive manufacturing. With DMLS’s affordability, speed, and superior design freedoms, companies and creators can build metal designs they never thought possible and produce accurate metal components.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WP

-

Product name:

-

Custom SLM Metal Aluminum 316L Stainless Steel 3D Printing service

-

Material:

-

Aluminum, stainless steel, titanium, hard steel, nickel

-

Process:

-

Direct Metal Laser Sintering (DMLS) 3D Printing Service

-

Surface treatment:

-

Sanding, high polishing, chrome plating, anodizing, sand blasting

-

Application:

-

Mechanical parts, engineering parts, medical device, auto parts

-

Service:

-

OEM / ODM 3D printing service

-

Equipment:

-

ZRapid Tech metal 3d printer

-

Keyword:

-

Metal 3d printing service

-

Drawing Format:

-

2D/(PDF/CAD/DWG)3D(STL/OBJ/IGES/STEP)

-

Tolerance:

-

+- 0.2- 0.3mm

Quick Details

-

CNC Machining or Not:

-

Not CNC Machining

-

Material Capabilities:

-

Aluminum, Hardened Metals, Stainless steel, Titanium

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WP

-

Product name:

-

Custom SLM Metal Aluminum 316L Stainless Steel 3D Printing service

-

Material:

-

Aluminum, stainless steel, titanium, hard steel, nickel

-

Process:

-

Direct Metal Laser Sintering (DMLS) 3D Printing Service

-

Surface treatment:

-

Sanding, high polishing, chrome plating, anodizing, sand blasting

-

Application:

-

Mechanical parts, engineering parts, medical device, auto parts

-

Service:

-

OEM / ODM 3D printing service

-

Equipment:

-

ZRapid Tech metal 3d printer

-

Keyword:

-

Metal 3d printing service

-

Drawing Format:

-

2D/(PDF/CAD/DWG)3D(STL/OBJ/IGES/STEP)

-

Tolerance:

-

+- 0.2- 0.3mm

What is DMLS/SLM?

DMLS / SLM 3d printing service belong to the powder bed fusion 3D printing family. The two technologies have a lot of similarities: both use a laser to scan and selectively fuse (or melt) the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in both processes are metals that come in a granular form.

Materials

Metal 3D Printing Material Options at WayNe ProtoType

Below is our available metal alloys for 3D printing. Various heat treatments are available depending on material.

Below is our available metal alloys for 3D printing. Various heat treatments are available depending on material.

|

Material Name

|

Layer Thickness

|

Apparent Density

|

Tensile Strength

|

Yield Strength

|

|

Aluminum (AlSi10Mg)

|

15-53μm

|

1.45g/cm3

|

≥330Mpa

|

≥245Mpa

|

|

Stainless steel (316L)

|

15-53μm

|

3.9g/cm3

|

≥560Mpa

|

≥480Mpa

|

|

Titanium (TC4)

|

Titanium (TC4)

|

2.5g/cm3

|

≥600Mpa

|

≥540Mpa

|

|

Harden Steel(MS1)

|

15-53μm

|

4.3g/cm3

|

≥1090Mpa

|

≥1000Mpa

|

|

Nickel base alloy(GH4169)

|

15-53μm

|

4.4g/cm3

|

≥980Mpa

|

≥700Mpa

|

Size and Tolerance

Direct metal laser sintering (DMLS) is an industrial metal 3D printing process that builds fully functional metal prototypes and production parts in 7 days or less. A range of metals produce final parts that can be used for end-use applications.

|

Capabilities

|

Description

|

|

Maximum build size

|

280*280*350mm (11''*11''*13.7'')

|

|

Standard lead time

|

4 days

|

|

Dimensional accuracy

|

+/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter

|

|

Layer thickness

|

.0012” - .0016" depending on material

|

|

Surface Roughness

|

150-400 µin Ra, depending on build orientation and material used for the build

|

Surface Finish

Standard

Standard: In addition to the removal of support structures, the part surface is media blasted to provide a uniform finish.

Polished

Black anodized

Additional DMLS post-processing, such as CNC Machining of features and polishing, are evaluated on a case-by-case basis and can be

requested in the quoting tool.

requested in the quoting tool.

Ideal DMLS Applications

Direct metal laser sintering (DMLS) is an additive metal printing technology that builds metal parts from a CAD file by

selectively fusing stainless steel or aluminum powder into thin layers.

Direct metal laser sintering’s layer-by-layer printing allows multiple parts to be combined during the printing process. With

traditional manufacturing processes, metal parts are machined or metal casted into several parts and assembled. Printing an all-in-one assembly strengthens the finished part while reducing the weight and cost of production significantly. DMLS techniques can also create parts at a high density. This is ideal for parts under high pressure such as in oil and gas industries.

Rapid Tooling

selectively fusing stainless steel or aluminum powder into thin layers.

Direct metal laser sintering’s layer-by-layer printing allows multiple parts to be combined during the printing process. With

traditional manufacturing processes, metal parts are machined or metal casted into several parts and assembled. Printing an all-in-one assembly strengthens the finished part while reducing the weight and cost of production significantly. DMLS techniques can also create parts at a high density. This is ideal for parts under high pressure such as in oil and gas industries.

Rapid Tooling

Because DMLS parts are strong yet lightweight, they are widely used for rapid tooling, fixtures, and jigs.

Rapid Prototyping

DMLS metal laser printing is typically affordable and fast, and therefore is often used to make proof-of-concept models and fully functional late-stage prototypes.

Production

Cast-quality finish (fully dense) and durable materials make DMLS printing a favorite technology for end-use products.

Rapid Prototyping

DMLS metal laser printing is typically affordable and fast, and therefore is often used to make proof-of-concept models and fully functional late-stage prototypes.

Production

Cast-quality finish (fully dense) and durable materials make DMLS printing a favorite technology for end-use products.

Recommend Products

SLA 3d printing service

SLA(Stereo Lithography Apparatus): uses an ultraviolet (UV) laser to turn light-sensitive resin (a liquid material that becomes hard when ultraviolet light is shined on it) into solid 3D objects, layer by layer.

Material:

Resin (ABS-Like and Acrylic-like)

Application: SLA: is very good way to make the complex structure and small parts with good tolerance and very good surface finish, can be paint in different colors.

MJF 3d printing service

Multi Jet Fusion or MJF 3D printing technology is perfect for those times when you are looking for lower porosity, short lead times and unsurpassed surface quality. If you are manufacturing complex end-use parts and have decided to produce it in a low

volume, then MJF can be the best option for you.

volume, then MJF can be the best option for you.

Part is made by HP printer, and has got very good strength, now it is mostly in grey black color.

Material: PA11, PA12, PA2200, PA12GB

CNC machining services

Material: Aluminum, stainless steel, brass, hard steel, titanium. bronze.

Hot Searches