- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Requirments

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized size

-

Warranty:

-

1 Year

-

Product name:

-

ATOP Stainless Steel Rainbow Color PVD Vacuum Coating Machine

-

Coating Method:

-

Vacuum Base Magnetron Sputtering

-

Technology:

-

Magnetron Sputtering+multi-arc Ion Coating

-

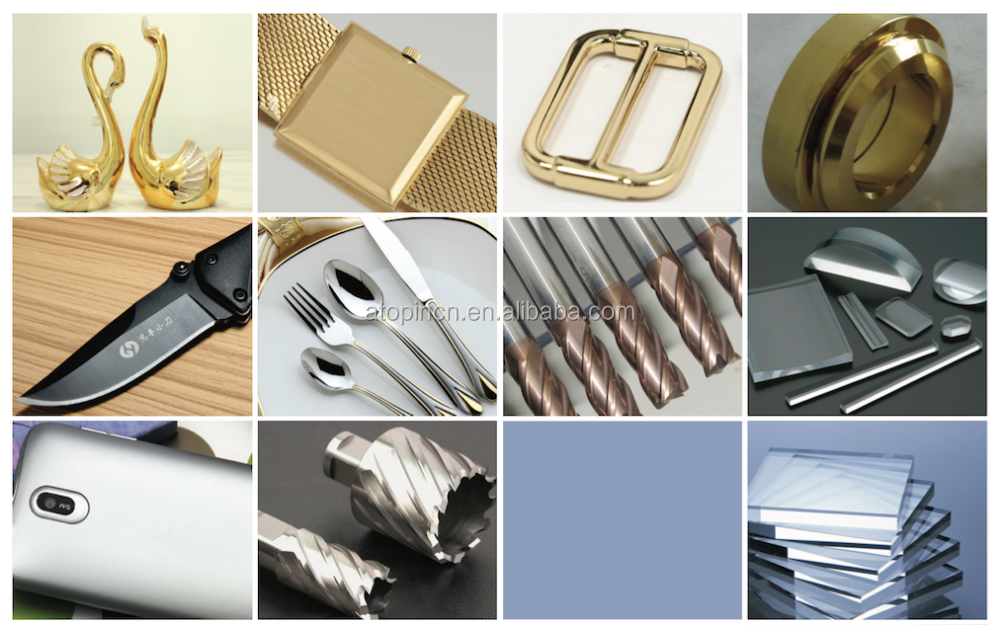

Application:

-

Crafts,Gifts,Hardware appliances,etc

-

Coating film:

-

Decorative Film,function film

-

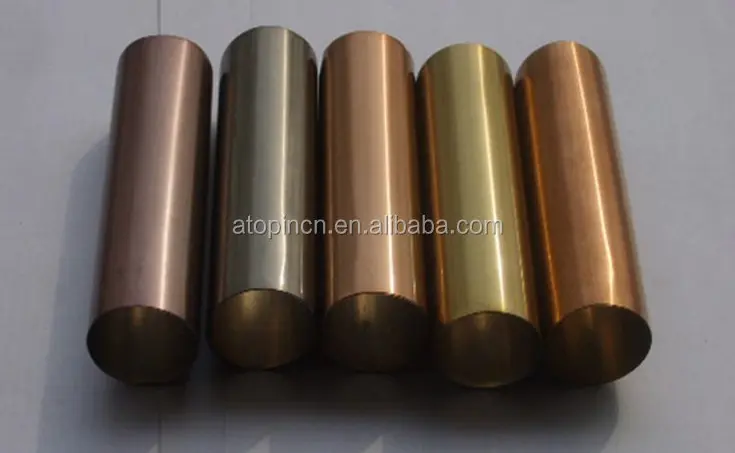

Coating color:

-

Multi Color Etc

-

Main Feature:

-

equipment ion source

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Weight:

-

4t-8t

-

Certification:

-

CE ISO9001

Quick Details

-

Machine Type:

-

PVD COATING MACHINE

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ATOP

-

Voltage:

-

Requirments

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized size

-

Warranty:

-

1 Year

-

Product name:

-

ATOP Stainless Steel Rainbow Color PVD Vacuum Coating Machine

-

Coating Method:

-

Vacuum Base Magnetron Sputtering

-

Technology:

-

Magnetron Sputtering+multi-arc Ion Coating

-

Application:

-

Crafts,Gifts,Hardware appliances,etc

-

Coating film:

-

Decorative Film,function film

-

Coating color:

-

Multi Color Etc

-

Main Feature:

-

equipment ion source

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Weight:

-

4t-8t

-

Certification:

-

CE ISO9001

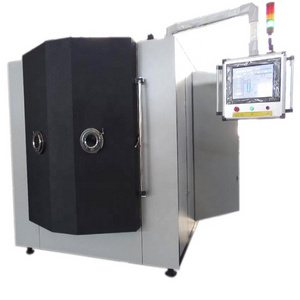

ATOP Stainless Steel Rainbow Color PVD Vacuum Coating Machine

1. It equipments cryogenic ion secondary source, some substrate without heating the material, It can directly do the cold plating film at room temperature, save energy, increase productivity.

2. The maximum of the temperature for tool coating chamber can 600 degrees, In addition to the tool Coater coating applications require heating device, other applications do not need the device.

3. High deposition rate, High coating speed, it can be widely used to do the decorative coating, functional coating on a variety of products. So it is a ideal equipment to do the high-grade and best coating for mass production.

4. Magnetron sputtering principle is based on the theory of the cathode glow discharge, it expend the cathode surface magnetic field near the work piece surface. Then it improves the sputtered atom ionization rate. It keeps the magnetron sputtering uniformity, also can improve the surface shining effect.

5. The arc plasma evaporation source is reliable, it can work under 40A current in optimizing the cathode and the magnetic field structure, it will happen atomic diffusion between the coating and the material. It also has the advantages that lon Beam Assisted Deposition.

6. Vacuum pumping system, electric control system and complete vacuum coating system can be customized according to user requirements.

PACKAGE:

Packed in standard export packing.

DELIVERY TIME:

Delivery: 45-70 days after the day of deposit payment (except holidays).

Machine acceptance inspection: we will inform the customer the test date of the machine within the delivery date. The customer can arrange the exact date to our workshop to inspect the machine. When the machine passing by the inspection, the customer pay the balance payment and we will transport the machine to Shanghai Port.

About Us

Vacuum coating is the major business of Atop Industry Co.,Ltd, We have more than 20 years of experience in the industry, our factory has obtained ISO quality management system and CE certificate. 100% Strictly carry on the design, production and testing to each equipment under ISO9001: 2008 quality management system, which ensures the stability and high quality products providing to tens of thousands of customers use.

Our main products include continuous magnetron sputtering coating production line (SiO2, ITO, AZO, TCO, low-e) plane arc tooling coating machines , multifunctional intermediate frequency magnetron sputtering coating equipment, Multi-arc compound ion coating machine, optical coating machine and ion plating technology, including : unbalanced magnetron, intermediate frequency magnetron sputtering and arc evaporation source, ion source auxiliary coating and the combination of a variety of technical features. The rolling coating machine which takes the high frequency induction evaporation technology can satisfy the PET, PVC, OPP, CPP strip material, laser holographic anti-counterfeiting materials such as film, capacitors, polyester cloth and other vacuum aluminum plating and evaporation of the medium material requirements.

UP to now, our company has been serving more than thousands of customers widely in solar photovoltaic (PV), low radiation coated glass, flat panel display, semiconductor, light, hardware clock, mold, electron, food, plastics and other industries.

With stable-quality, high-efficient products and excellent customer service , Atop Industry Co.,Ltd has gained great reputation from more and more domestic and foreign customers!

Turnkey Service: including film research and equipment research, manufacturing, installation, debugging, trial production, personnel training. our company has perfect after-sales service network and more than 10 individuals experienced after-sales service team, all-round for customers solve various problems of vacuum equipment and process.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Q: How much is the price o f the products?

A: Our products are customized, please tell us you requirements and configuration of the product, the price varies greatly for different configuration.

Q: How long is your delivery time?

A: Generally 45-70 days after deposit.

Q: How much is the MOQ?

A: MOQ is 1 set

Q: What is your terms of payment ?

A: T/T with 30% deposit, 70% before delivery.