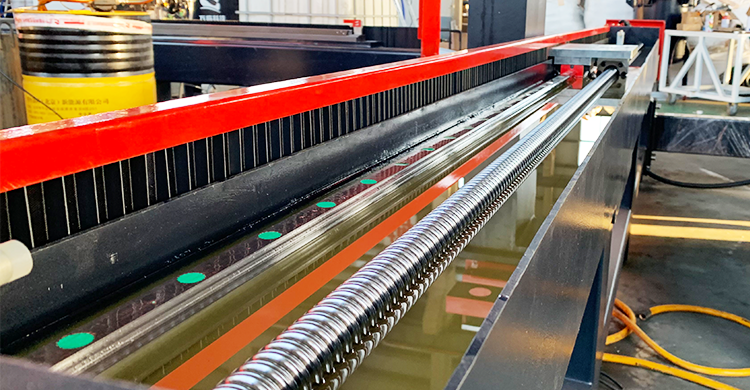

The guide screw is completely immersed in the oil tank, which can fully lubricate and prevent the wear of the transmission system from the splashing of abrasive and water. And it has high cutting accuracy, but also greatly improves the service life of the equipment, and solves the serious accuracy attenuation problem of water jet cutter in the past, and the cutting is accurate at any time

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

150

-

Cutting Accuracy(mm):

-

0.1

-

Brand Name:

-

WONLEAN

-

Voltage:

-

420MPA

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

2000MM*1500MM

-

Weight (KG):

-

5000 KG

-

Name:

-

Water Jet Cutting Machine

-

Type:

-

5 axis cnc waterjet

-

Keyword:

-

cnc water jet cutting machine

-

Application:

-

Material Cutting

-

Structure:

-

Oil immersion

-

Machine Cover:

-

Stainless Steel

-

Intensifier:

-

ACCUSTREAM

-

Main Motor:

-

SIEMENS Motor

-

Servo Motor:

-

Yaskawa

-

Rail Screw:

-

HIWIN

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Table Travel (X) (mm):

-

2000

-

Table Travel (Y) (mm):

-

1500

-

Table Travel (Z) (mm):

-

150

-

Cutting Accuracy(mm):

-

0.1

-

Brand Name:

-

WONLEAN

-

Voltage:

-

420MPA

-

Rated Power:

-

37KW

-

Dimension(L*W*H):

-

2000MM*1500MM

-

Weight (KG):

-

5000 KG

-

Name:

-

Water Jet Cutting Machine

-

Type:

-

5 axis cnc waterjet

-

Keyword:

-

cnc water jet cutting machine

-

Application:

-

Material Cutting

-

Structure:

-

Oil immersion

-

Machine Cover:

-

Stainless Steel

-

Intensifier:

-

ACCUSTREAM

-

Main Motor:

-

SIEMENS Motor

-

Servo Motor:

-

Yaskawa

-

Rail Screw:

-

HIWIN

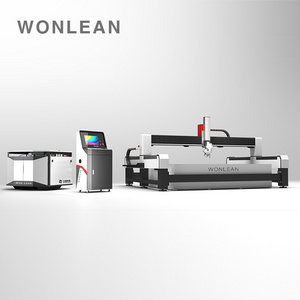

Waterjet Cutting Machine for glass, metal, stone and rubber, plastic, etc.

Product Description

16

Years

Experience

CNC WATERJET

CUTTING MACHINE

✔

Support non-standard customization

✔

Provide free sample trial cutting service for you

15 years of practice creates classic

WONLEAN new generation water jet cutting machine

√

All cast iron bed

√

Oil-immersed structure

√

Automatic variable pump

√

Fully intelligent system

Oil-immersed structure

Concrete casting bed

After finite element analysis, the bed is welded in one body by making full use of the optimum stress point and supporting structure. After the aging treatment, concrete is poured into the bed body, which has strong stability and excellent shock absorption, greatly reduces the stress of the machine bed and maintains the long-term guarantee of accuracy

Split structure

Stainless steel body

The X,Y,Z axis adopts double sealing design, with external high-quality stainless steel brushed shell and high-quality dust-proof folding cloth, which can provide effective hard protection and full sealing for the equipment, and is the most effective sealing form of waterjet cutter at present

Direct connection transmission system

The high-power servo motor is directly connected with the large-diameter guide screw. Compared with the traditional synchronous pulley belt connection, it has less transmission loss, higher precision, better stability. High accuracy without the slightest error

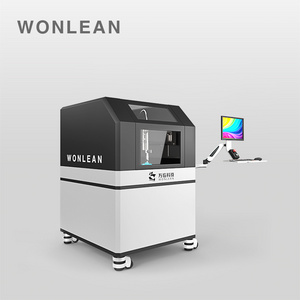

Intelligent 3D cutting

It can achieve fixed and variable angle 3D cutting within 75 degrees. The cutting head mechanism is made of aluminum alloy, with light weight, high strength and small load. The offset of the cutting position under the reaction of 380Mpa high pressure water is less than 0.01 mm, and the cutting accuracy is extremely high

Tilting compensation system

Through the dynamic compensation of the intelligent five axis software and two Japanese Yaskawa servo motors, the "V"shaped incision of the waterjet is accurately compensated to make the cutting incision vertical up and down or achieve bevel cutting within 8 degrees

Intelligent variable pressurization system

Equipped with a variable oil pump and an intelligent variable high pressure system composed of four imported valve bodies, which can intelligently adjust the amount of oil according to the pressure requirements and has high cutting efficiency, better oil temperature control and more energy-saving, so that each pressurization is just right

Wireless remote control handle everything under control

More flexible and convenient for tool setting Control equipment operation at any time Display feed values in real time

Magnetic design for easy access

Magnetic design for easy access

Intelligent identification and one-touch processing

Identify CAD E-drawings, automatically generate cutting path and access parameters, reduce manual coding and repeated operations, simple operation, improve production capacity

The main components adopt internationally renowned brands

World-leading quality accomplishes the WONLEAN classic

|

High pressure system specifications

|

|

|

|

|||

|

Model

|

WL30018Z

|

WL38030Z

|

WL42037Z

|

|||

|

Max. Pressure

|

300Mpa

|

380Mpa

|

420Mpa

|

|||

|

Continuous working pressure

|

260Mpa

|

340Mpa

|

380Mpa

|

|||

|

Power

|

18KW

|

30KW

|

37KW

|

|||

|

Maximum water flow

|

3.7L/min

|

3.7L/min

|

3.7L/min

|

|||

|

Maximum nozzle diameter

|

0.33mm

|

0.33mm

|

0.33mm

|

|||

|

Working power supply

|

380V/50HZ

|

|

|

|||

|

Technical parameters of gantry cutting platform

|

|

|

|

|

|

|

||||||

|

Model

|

WL2015BA

|

WL2030BA

|

WL3020BA

|

WL2040BA

|

WL2060BA

|

WL3060BA

|

||||||

|

X axis

|

2000mm

|

2000mm

|

3000mm

|

2000mm

|

2000mm

|

3000mm

|

||||||

|

Y axis

|

1500mm

|

3000mm

|

2000mm

|

4000mm

|

6000mm

|

6000mm

|

||||||

|

Z axis

|

150mm

|

150mm

|

150mm

|

150mm

|

150mm

|

150mm

|

||||||

|

Running speed

|

9000mm/min

|

|

|

|

|

|

||||||

|

Cutting accuracy

|

±0.1mm

|

|

|

|

|

|

||||||

|

control precision

|

±0.01mm

|

|

|

|

|

|

||||||

|

Repeat accuracy

|

±0.05mm

|

|

|

|

|

|

||||||

Product Advantages:

1.Cutting accuracy is up to 0.1mm.

2.The main core components of Intensifier is made in USA.

3.The guide screw with oil-immersed structure different from the traditional dry structure. The linear guide rail and ball screw are immersed in the oil tank ,which can fully lubricate the guide screw and further isolate the water and abrasive,so as to maintain the cutting accuracy.

4.The high-power servo motor and the guide screw are connected directly by flexible coupling, which eliminates the gap of traditional belt connection and improves the cutting precision.

Why Choose Us

Hot Searches