It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing the workpiece on the machine’s table while the cutting tools attached to the spindle rotates and moves to shape the workpiece into a finished product.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TF

-

Brand Name:

-

TF

-

Tolerance:

-

ISO 2768-mH or as per drawing

-

Materials:

-

Aluminum, brass, ABS, POM, PA6, nylon, PP etc

-

Testing facility:

-

3D image measuring instrument

-

Service:

-

CNC turning services, CNC milling services

-

Color:

-

As request

-

Equipment:

-

3/4/5-axis machining center

-

Minimum order:

-

1pcs

-

Surface roughness:

-

Ra0.01-1.6

-

Process:

-

Cnc machining+deburrs

-

Application:

-

Industry

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Other

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

TF

-

Brand Name:

-

TF

-

Tolerance:

-

ISO 2768-mH or as per drawing

-

Materials:

-

Aluminum, brass, ABS, POM, PA6, nylon, PP etc

-

Testing facility:

-

3D image measuring instrument

-

Service:

-

CNC turning services, CNC milling services

-

Color:

-

As request

-

Equipment:

-

3/4/5-axis machining center

-

Minimum order:

-

1pcs

-

Surface roughness:

-

Ra0.01-1.6

-

Process:

-

Cnc machining+deburrs

-

Application:

-

Industry

CNC Milling:

CNC turning:

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations used.

5-axis CNC Machining:

5-axis CNC machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting.

|

Product name

|

CNC machining services

|

|

Surface treatment

|

Anodizing, bead blasting, black oxide, polishing, powder coating, painting, brushing, electroplating, passivation, or customer’s requirements.

|

|

Material capacities

|

Metal: aluminum alloy, stainless steel, brass, copper, tool steel, carbon steel, iron.

Plastic: ABS, POM, PC(Poly Carbonate), PC+GF, PA(nylon), PA+GF, PMMA(acrylic), PEEK, PEI, etc.

|

|

CNC processing scope

|

CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC lathe, high precision 5-Axis turning-milling combined machining.

|

|

Tolerance

|

±0.002 ~ ±0.005mm

|

|

Surface roughness

|

Min Ra 0.02~3.2

|

|

Drawing format

|

IGS, STP, STEP, X_T, DXF, DWG, Pro/E, PDF, PNG, JPG.

|

|

Package

|

Tissue paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc, can be customized according to customer's requirements.

|

|

Delivery

|

DHL, FedEx, EMS, UPS, or customer's requirements.

|

|

Aluminum

|

AL1100, AL1050, AL1070, AL1060, AL2014, AL2017, AL2024, AL3003, AL5052, AL5754, AL6061, Al6063, AL6082, AL7075, LY12, LY11, 2A12 etc.

|

|

Stainless steel

|

SS201, SS301, SS303, SS304, SS316, SS416 etc.

|

|

Steel

|

4140, 4340, Q235, Q345B, 20#, 45#, DC01, SPCC, SPHC, CGCC, A36, 1213, 12L14, 1215 etc.

|

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, C36000 etc.

|

|

Copper

|

C11000, C12000, T1, T2, T3 etc.

|

|

Titanium alloy

|

TC1, TC2, TC3, TC4, etc.

|

|

Plastic

|

ABS, PC, PP, PE, POM, delrin, nylon, PEEK, PEI, etc.

|

|

Basic size range

|

Fine

|

Medium

|

Coarse

|

Very coarse

|

|

0.5 up to 3

|

.05

|

± 0.1

|

± 0.2

|

-

|

|

Over 3 up to 6

|

± 0.05

|

± 0.1

|

± 0.3

|

± 0.5

|

|

Over 6 up to 30

|

± 0.1

|

± 0.2

|

± 0.5

|

± 1

|

|

Over 30 up to 120

|

± 0.15

|

± 0.3

|

± 0.8

|

± 1.5

|

|

Over 120 up to 400

|

± 0.2

|

± 0.5

|

± 1.2

|

± 2.5

|

|

Over 400 up to 1000

|

± 0.3

|

± 0.8

|

± 2

|

± 4

|

|

Over 1000 up to 2000

|

± 0.5

|

± 1.2

|

± 3

|

± 6

|

|

Over 2000 up to 4000

|

-

|

± 2

|

± 4

|

± 8

|

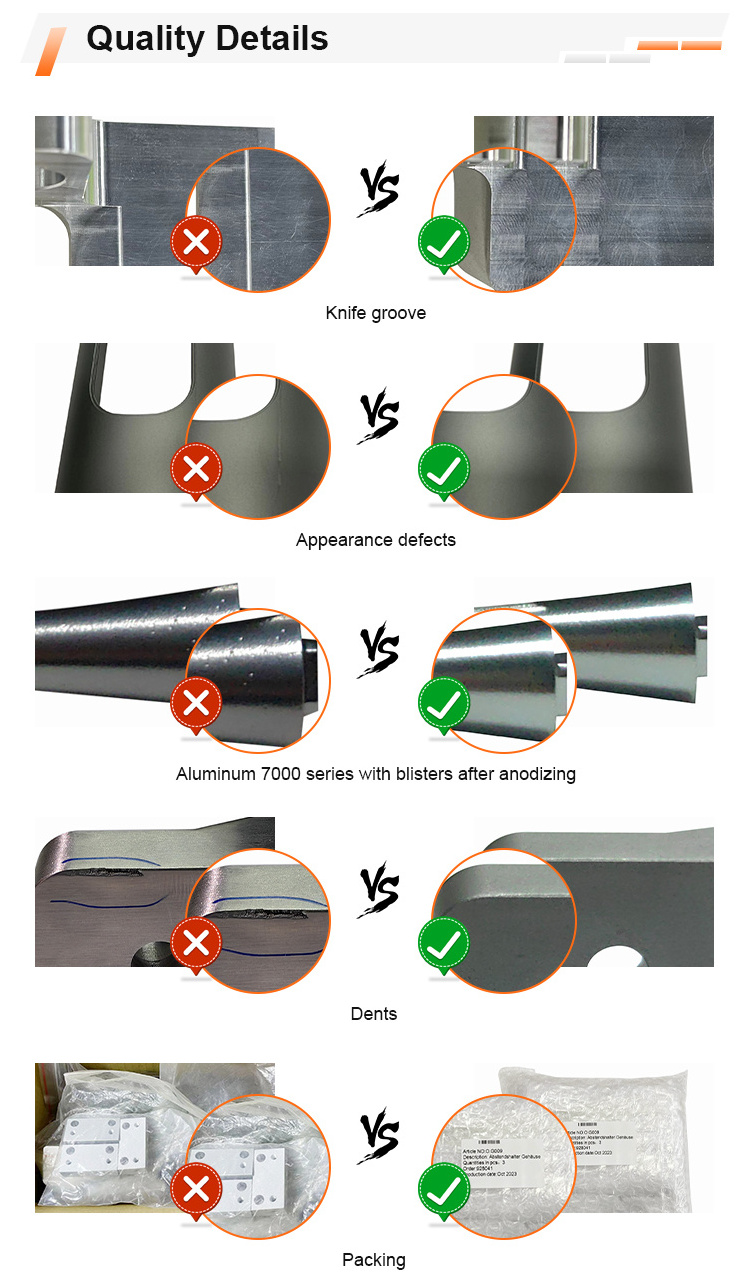

In order to live up to the trust of our customers, quality control and assurance is achieved through:

1. Comprehensive written procedures and policies.

2. Details records of incoming raw material.

3. Analysis of root cause of non conformances.

4. Fully equipped inspection department.

5. Consistent calibration and labeling of inspection tools.

Shenzhen Tuofa Technology Co., Ltd.

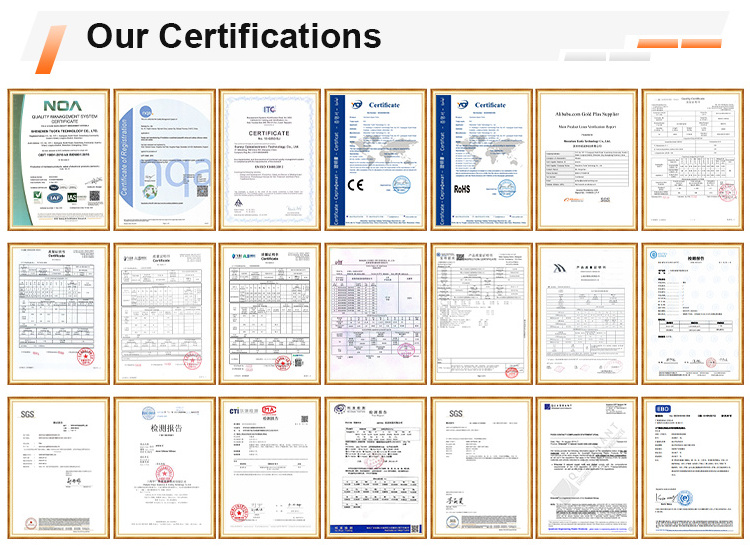

was established in 2006. We specialize in all kinds of CNC milling parts, CNC turning parts, 5-axis CNC machining, surface treatment, and assembly services. Commonly process materials are as follows: stainless steel, steel, titanium, plastic, aluminum, brass alloy, special metal ect. For surface finishing, we can supply as follows: electrogalvanizing, electroplating chromium, electroplating nickel, titanium plating, sandblasting anodizing, QPQ, polishing, and electrophoresis ect. We have passed validation of ISO9001, SGS, TUV, ROHS, CE ect, and we have got many awards from our customers. We can assemble andproduce one-stop service instead of customers, eliminating intermediate links, savingtime and cost for customers.

|

1

|

Q: Are you a factory or trading company?

A: Tuofa is an experience factory in Shenzhen of China, welcome to visit our factory.

|

|

2

|

Q: Can you provide one-stop sevice including of material, processing, finish, assembly etc?

A: Yes, we can.

|

|

3

|

Q: What's your minumum order quantity(MOQ)?

A:

1

piece, small order quantities are welcome.

|

|

4

|

Q: Will my design drawings be safe when you get it?

A: Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

|

|

5

|

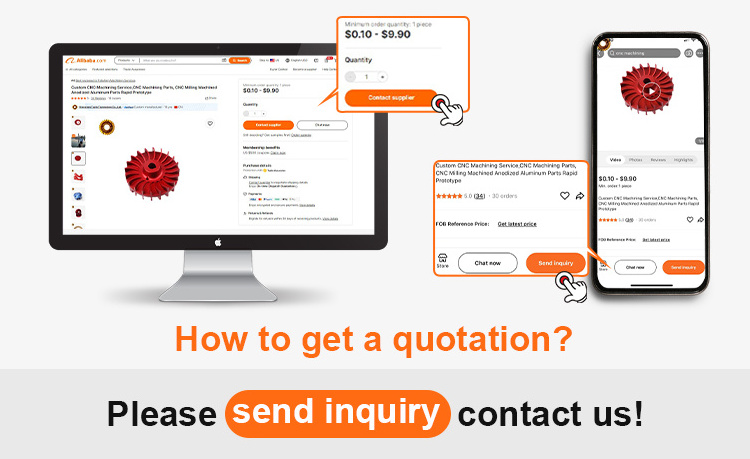

Q: How can I get a quotation?

A: To get prices in

1

hour, please provide information below with your inquiry:

1) Drawings format 2d(dwg/dxf/pdf)/3d(step/stp/igs) or sample.

2) Material requirement.

3) Surface treatment.

4) Quantity.

5) Any special demands or requirements, such as packing, labels, delivery, etc.

|

|

6

|

Q: How do you control the quality?

A: Strictly adhere to the

ISO9001 Quality Management System

.

|

|

7

|

Q: What is the shipping method?

A: 1) Door to door service: DHL, UPS, FedEx, TNT.

2) The ocean shipping or air shipping is also available for big orders.

3) You also can use your own forwarder account.

|

|

8

|

Q: What is lead time for sample get?

A:

3

days fastest.

|

|

9

|

Q: How can I pay?

A: 1) Bank to bank wire transfer to accounts.

2) Paypal.

3) Western Union.

4) T/T.

5) Other.

|

|

10

|

Q: What is your after-sales service?

A: Please feedback to our sales, we will take action in 12 hours.

|

Hot Searches