- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PT

-

Year:

-

2022

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2500mm*1100mm*2100mm

-

Weight (T):

-

1.5 T

-

Model Number:

-

PT-CPP01

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

New Product 2022

-

Production capacity:

-

4 pieces/min

-

Working pressure:

-

≤ 45T

-

Working stroke:

-

Up stroke≤150mm,Down stroke≤150mm

-

Filling depth:

-

≤ 150mm

-

Product mold:

-

Can be customized according to the tablet features

-

Apply to shape:

-

Round,square,or special-shaped,suitable for a variety of shapes

-

Power supply:

-

7.5kw 9kw(Servo)

-

Weight&size:

-

2200mm*950mm*2050mm

Quick Details

-

Machine Type:

-

Single Column Hydraulic Press

-

Slide Stroke (mm):

-

700

-

Return Force (kN):

-

1500 kN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PT

-

Year:

-

2022

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2500mm*1100mm*2100mm

-

Weight (T):

-

1.5 T

-

Model Number:

-

PT-CPP01

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

New Product 2022

-

Production capacity:

-

4 pieces/min

-

Working pressure:

-

≤ 45T

-

Working stroke:

-

Up stroke≤150mm,Down stroke≤150mm

-

Filling depth:

-

≤ 150mm

-

Product mold:

-

Can be customized according to the tablet features

-

Apply to shape:

-

Round,square,or special-shaped,suitable for a variety of shapes

-

Power supply:

-

7.5kw 9kw(Servo)

-

Weight&size:

-

2200mm*950mm*2050mm

Product Description

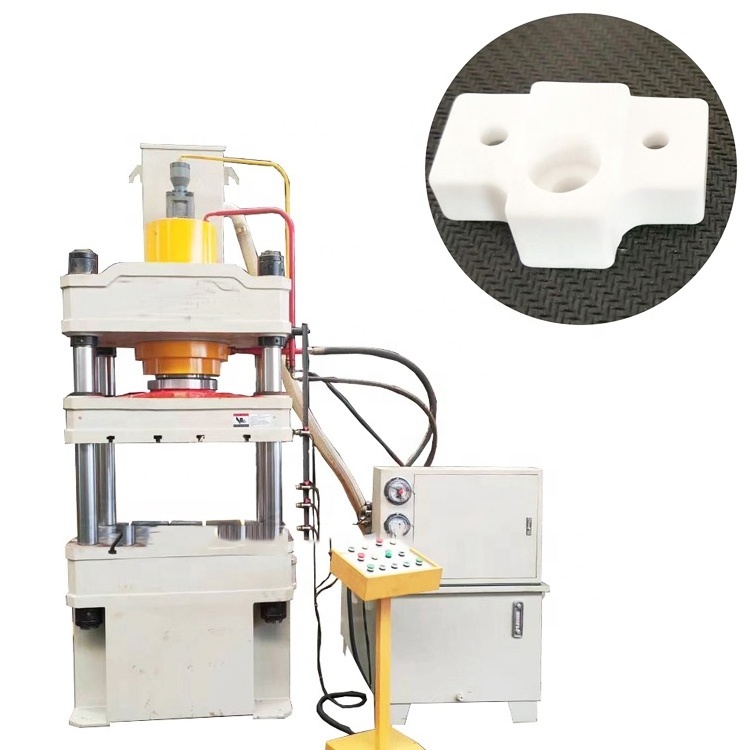

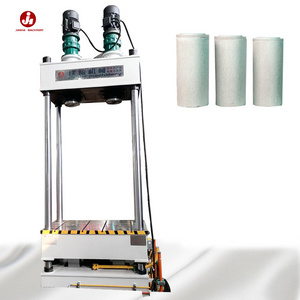

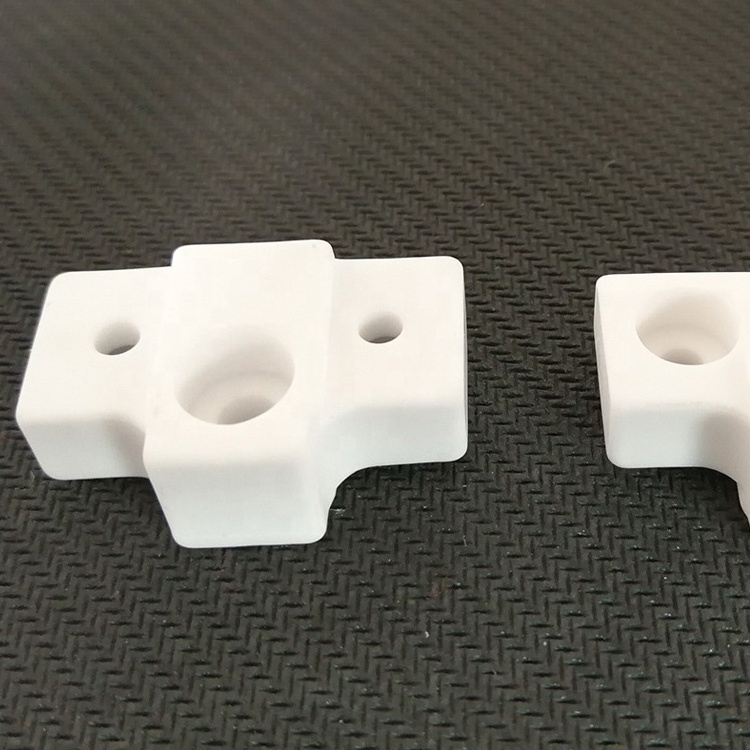

Ceramic Powder Press

Ceramic powder press molding is also called press molding. It is characterized by a low binder content, only a few percent (generally 7% to 8%), can be directly calcined without drying, and the body shrinks small, and can be automated.

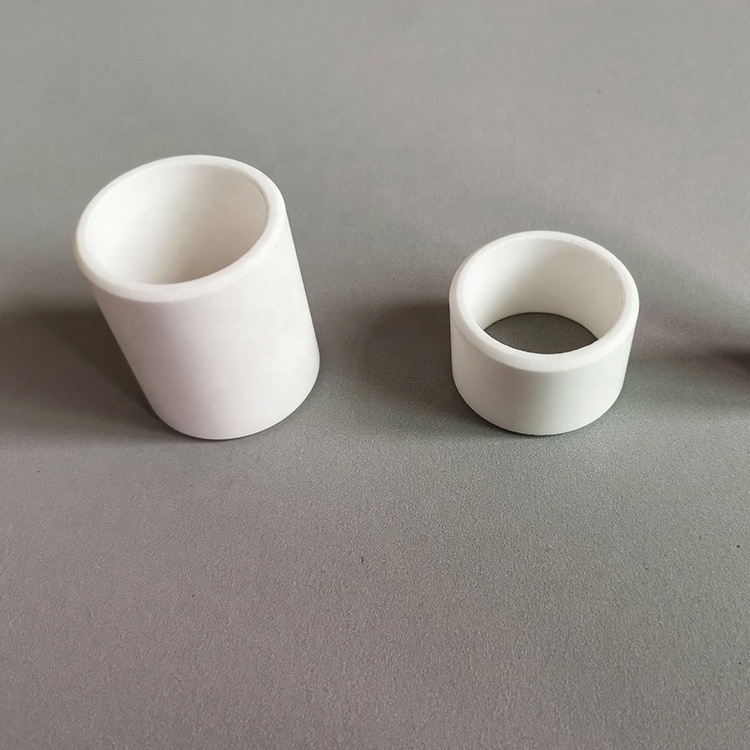

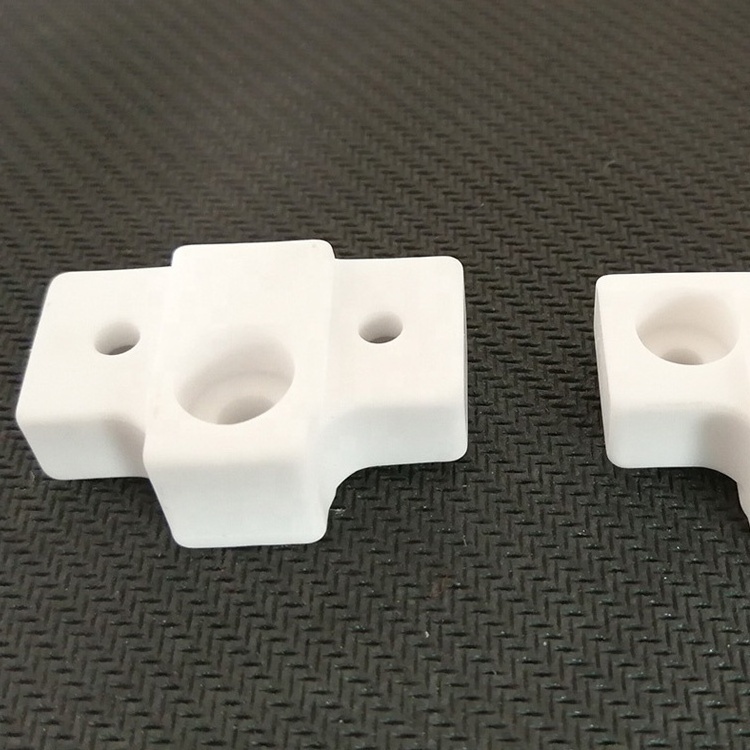

Finished products

Feature

* It is free to manufacture geometrically complex products directly.

* The molding cycle is short, only a few tenths to a few hundredths of the time of pouring and hot press molding, the strength of the blank is high, the production can be automated, and the management and control of the production process is also very convenient, suitable for mass production.

* Due to the good fluidity of the binder, the densities of the injection molded blanks are quite uniform.

* Due to the powder and binder mixing is very uniform, the gap between the powder is very small, the shrinkage characteristics of the sintering process is basically the same, so the products are uniform in all parts of the density with high geometric dimensional accuracy.

* The molding cycle is short, only a few tenths to a few hundredths of the time of pouring and hot press molding, the strength of the blank is high, the production can be automated, and the management and control of the production process is also very convenient, suitable for mass production.

* Due to the good fluidity of the binder, the densities of the injection molded blanks are quite uniform.

* Due to the powder and binder mixing is very uniform, the gap between the powder is very small, the shrinkage characteristics of the sintering process is basically the same, so the products are uniform in all parts of the density with high geometric dimensional accuracy.

Specification

|

Production capacity

|

4 pieces/min(the actual speed according to product process

requirement)

|

|

Working pressure

|

≤ 45T(1.Stepless adjustment 2.Bidirectional compress)

|

|

Working stroke

|

Up stroke≤150mm,Down stroke≤150mm(1.Stepless adjustment

2.Bidirectional compress)

|

|

Filling depth

|

≤ 150mm(1.Stepless adjustment 2.Bidirectional compress)

|

|

Product mold

|

Can be customized according to the tablet features(The mould can

compress 1 output more tablets percycle)

|

|

Apply to shape

|

Round,square,or special-shaped,suitable for a variety of

shapes,please consuit

|

|

Power supply

|

7.5kw 9kw(Servo)

|

|

Weight&size

|

2200mm*950mm*2050mm

(L*W*H)

|

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Hot Searches